Nuclear power station non-active engineering safety system

A safety system and passive technology, applied in the field of nuclear power plant safety equipment, can solve problems such as undiscovered pressure vessels, and achieve the effects of reducing construction costs, reducing quantities, and simplifying structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

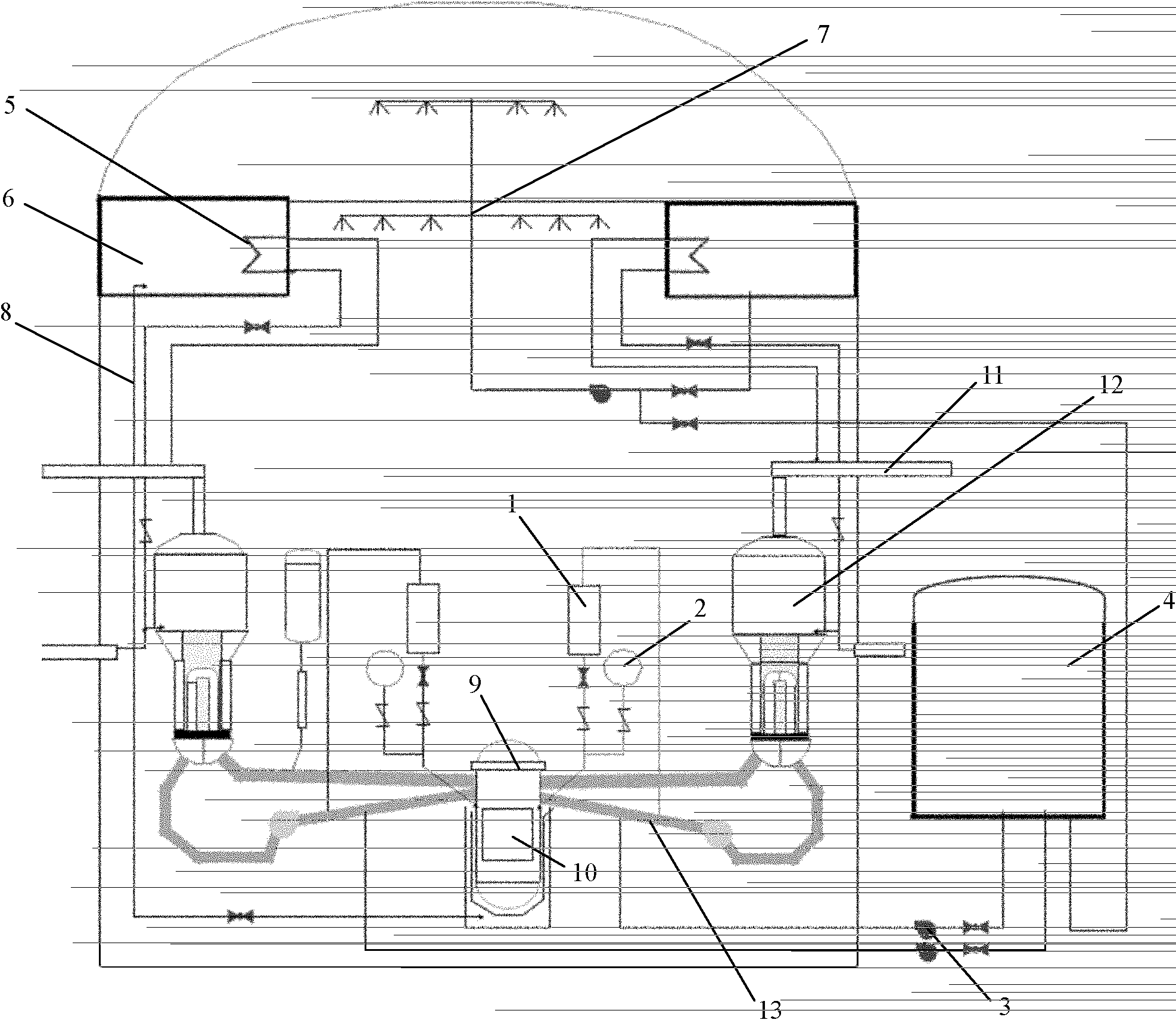

[0020] Such as figure 1 As shown, a passive special safety system for pressurized water reactor nuclear power plants includes several columns of passive high-pressure core water supply tanks 1 corresponding to the number of columns and the number of loops. The passive high-pressure core water supply tanks 1 is set higher than the core 10, and communicates with the primary circuit of the reactor through the safety injection pipeline, and the valve on the injection pipeline is triggered to open by the low pressure signal of the primary circuit. In addition, the ad hoc safety system also includes several rows of passive waste heat discharge heat exchangers 5 on the secondary side corresponding to the number of circuits, and the heat transfer tube bundles of each row of passive waste heat discharge heat exchangers 5 on the secondary side Immersed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com