Tower kettle of rectifying tower

The technology of a rectifying tower and a tower kettle is applied in the field of chemical equipment, which can solve the problems of lowering the liquid concentration, unfavorable rectification separation, affecting the concentration effect of the reboiler, etc., and achieves the effects of increasing the concentration, reducing the concentration and improving the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

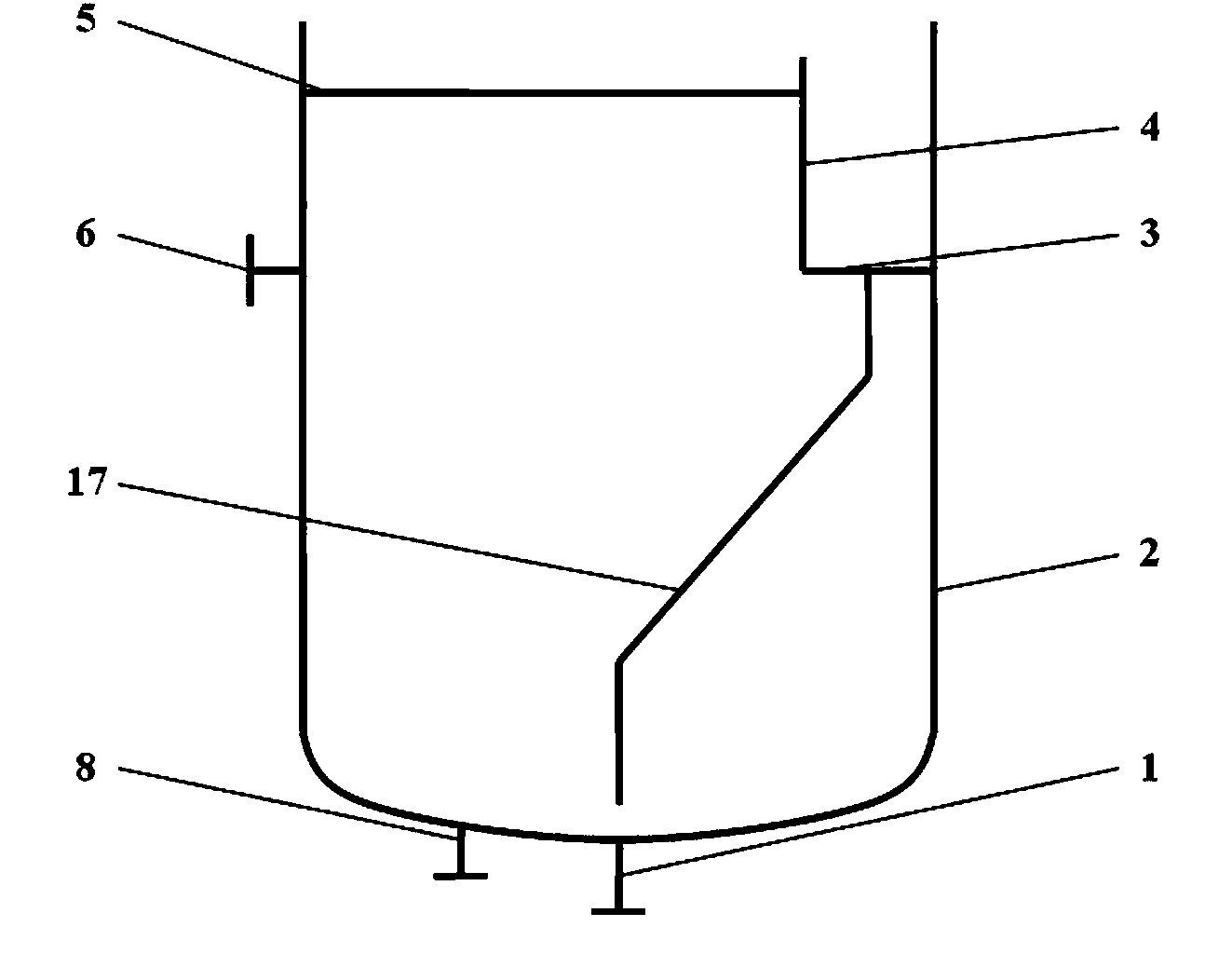

[0020] Combine below figure 2 And specific embodiment, the present invention is described in detail.

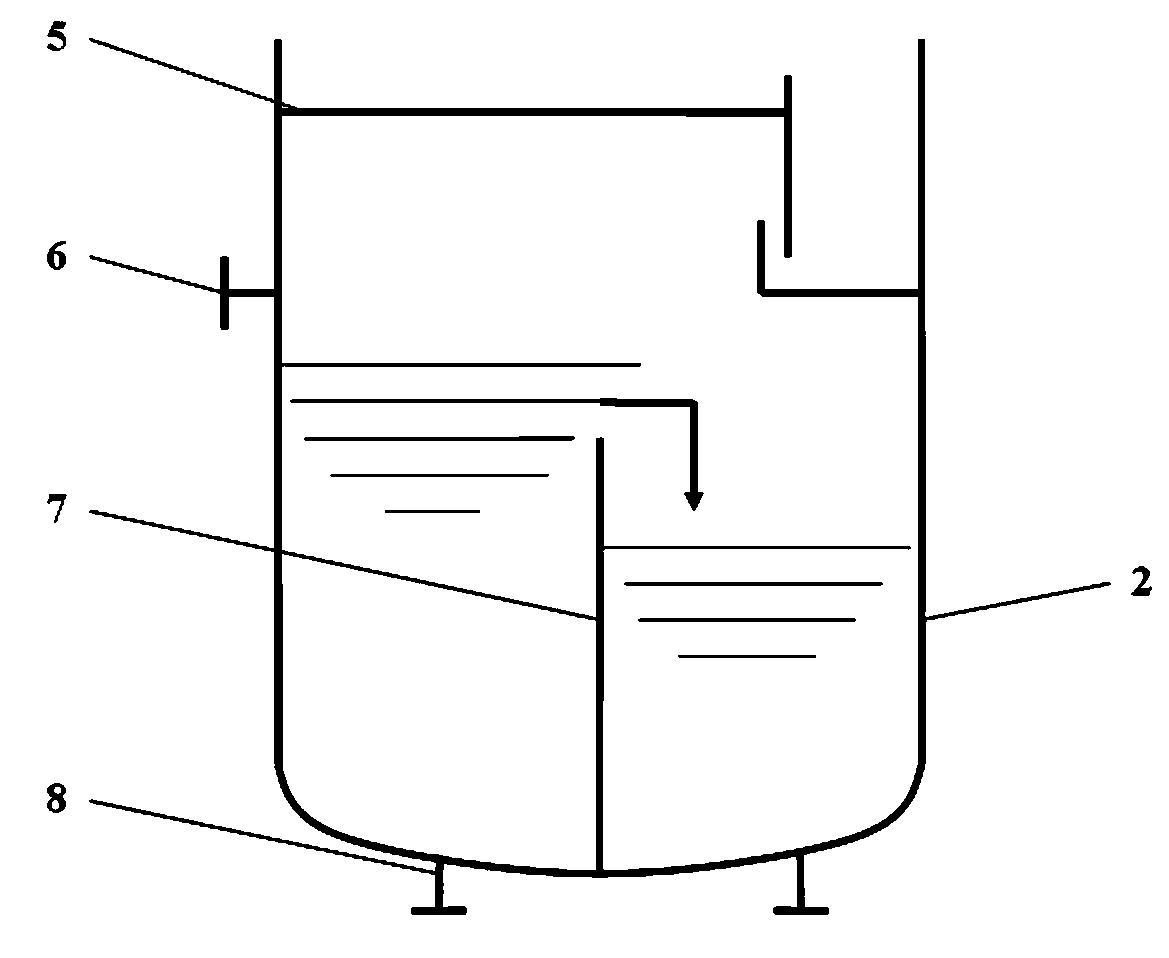

[0021] figure 2 It is a structural schematic diagram of the rectification tower still of the present invention, as shown in the figure, the rectifying tower tower still of the present invention comprises tower still 2, goes to the liquid outlet 1 of reboiler, from the vapor-liquid reflux inlet 6 of reboiler, The raffinate outlet 8, the bottom tray 5, the bottom downcomer 4, the bottom downcomer bottom plate 3, the bottom tray liquid guide pipe 17, open holes on the bottom downcomer bottom plate 3, the bottom tray liquid guide pipe 17 The upper end is connected to the hole in the bottom plate 3 of the bottom downcomer to close the hole, and the lower end is placed above the liquid outlet 1 of the reboiler and kept at an appropriate distance from the outlet. At the same time, change the gap between the bottom downcomer 4 and the bottom downcomer bottom plate 3 in the past, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com