Production method for refining propofol by dynamic accumulative distillation

A production method and technology of propofol, applied in the field of preparation of drug propofol, can solve problems such as cumbersome operation, difficult rectification and separation, large equipment investment, etc., achieve enhanced controllability, solve long operation time, improve Effect of Purity and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

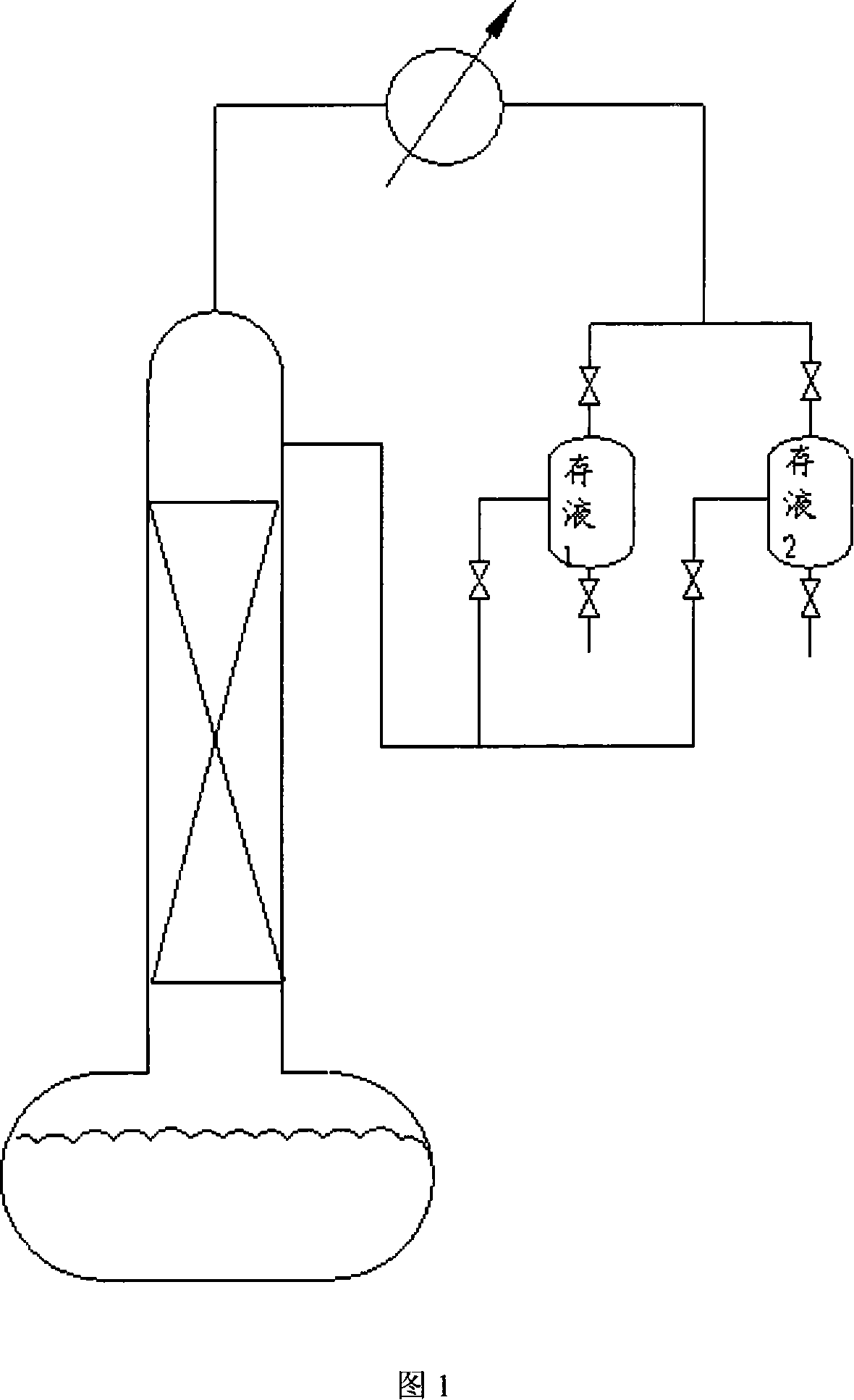

[0030] 1) Description of the distillation process

[0031] The tower diameter of the rectification tower is 200mm, among which there are 60 theoretical plates, the vacuum degree is 15mmHg, and the liquid storage tank is arranged in the rectification tower.

[0032] Propofol crude product 200kg (content 61%), add in the rectifying tower, heat total reflux 40min, open the discharge valve on the liquid storage tank to extract light components, close the discharge valve, continue total reflux 20min, then open The discharge valve continues to extract light components, repeat the operation, and as the light components are extracted one after another, the temperature at the top of the rectification tower will gradually rise. Track and monitor the content of propofol in the produced light components, and collect each production fluid separately after passing the test, and change to produce once every 15 minutes. When it is detected that heavy components are distilled out, the extract...

Embodiment 2

[0034] The tower diameter of the rectification tower is 200mm, among which there are 60 theoretical plates, the vacuum degree is 15mmHg, and the liquid storage tank is arranged in the rectification tower.

[0035] Propofol crude product 200kg (content 98.5%), add in the rectifying tower, heat total reflux 40min, open the discharge valve on the storage tank to extract light components, close the discharge valve, continue total reflux 30min, then open The outlet valve continues to extract light components and repeat the operation. When the temperature at the top of the rectification tower is stable, use TLC to track and monitor the content of propofol in the extracted fraction. After passing the test, collect each output liquid separately and change it to every 15min. Take it once. When it is detected that heavy components are distilled out, the extraction is stopped and the rectification ends. HPLC detects each extract, and the content of propofol ≥ 99.8% is 144.2Kg, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com