Sugar palm analgesic extract and preparation method and use thereof

A technology of extract and sugarcane, applied in the field of sugarcane analgesic extract and preparation thereof, can solve the problems of small application range of sugarcane extract, poor pain relief effect of sugarcane extract chelidonate, etc., and avoid macropores. Effects of resin overloading, increasing foot pain threshold, and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

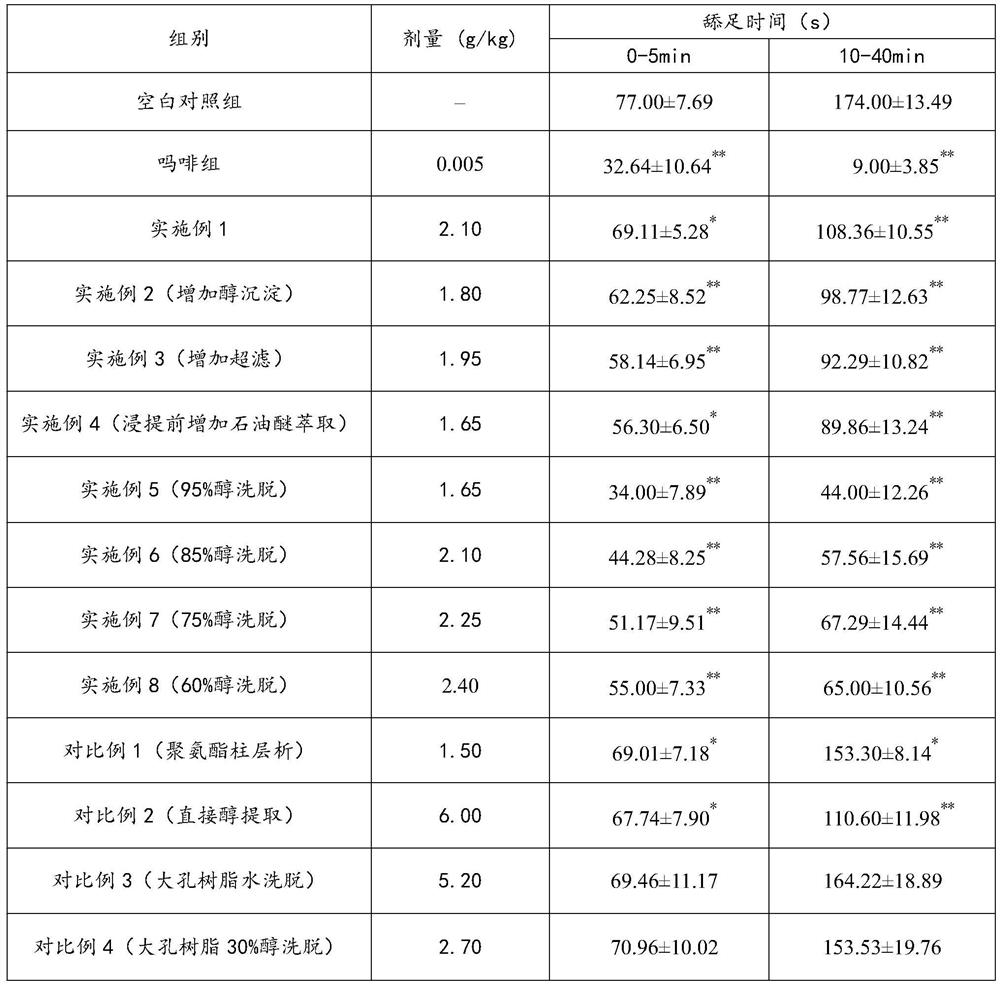

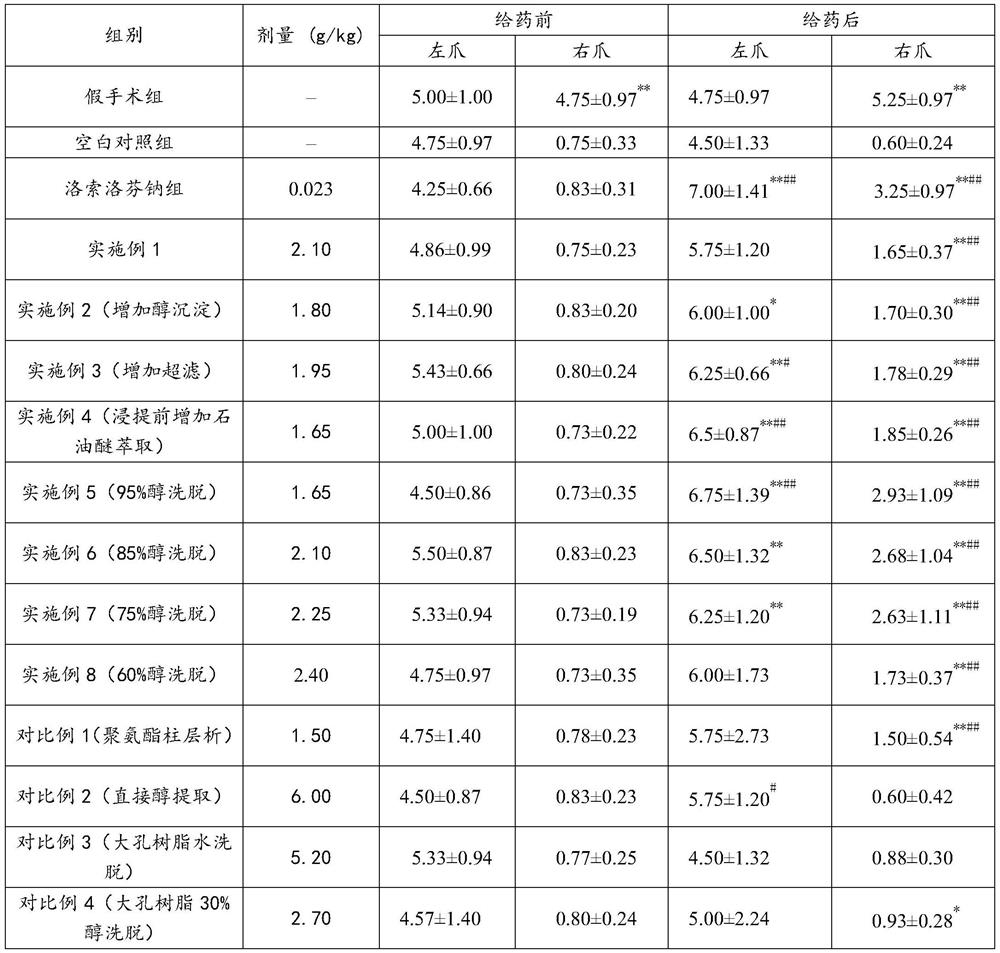

Examples

Embodiment 1

[0026] Embodiment 1 (claim 1)

[0027] (1) Put 1 kg of sugarcane fruit in a pulverizer and grind it to 60 mesh, then add 1.5L of ethanol solution with a concentration of 65% and soak for one day, recover the soaking solution, and add 1.5L of 65% ethanol solution to the sugarcane fruit again. % ethanol solution for immersion for one day, and combine the two immersion solutions to obtain the extract;

[0028] (2) Concentrate the above extract under reduced pressure at 60°C for 2 hours to remove ethanol to obtain an extract, measure the relative density of the extract to be 1.25, then add water to the extract and stir continuously, and measure with a hydrometer at the same time until the relative density is obtained 1.10 extract dilution;

[0029] (3) Adopt the macroporous resin that model is R8-18 to extract the medicinal extract dilution that obtains through macroporous adsorption resin, be 100:20 (g / g) respectively according to the consumption of macroporous resin consumption...

Embodiment 2

[0030] Embodiment 2: (increase alcohol precipitation)

[0031] (1) Put 1 kg of sugarcane fruit in a pulverizer and grind it to 55 mesh, then add 1.5L of ethanol solution with a concentration of 65% and soak for one day, recover the soaking solution, and add 1.5L of 65% ethanol solution to the sugarcane fruit again. % ethanol solution for immersion for one day, and combine the two immersion solutions to obtain the extract;

[0032] (2) The extract was concentrated under reduced pressure at 60°C for 2 hours to remove ethanol to obtain an extract, and the extract obtained was first added to 3L of 95% ethanol solution in volume, left to stand for 24 hours, and the precipitate was removed to get the supernatant of the extract. Measure the relative density of the supernatant of the extract to be 1.25, then add water to the supernatant of the extract and stir continuously, while measuring with a hydrometer until obtaining a dilution of the extract with a relative density of 1.10;

...

Embodiment 3

[0034] Embodiment 3: (increase ultrafiltration)

[0035] (1) Put 1 kg of sugarcane fruit in a pulverizer and grind it to 50 mesh, then add 1.5L of ethanol solution with a concentration of 65% and soak for one day, recover the soaking solution, and add 1.5L of 65% ethanol solution to the sugarcane fruit again. % ethanol solution for immersion for one day, and combine the two immersion solutions to obtain the extract;

[0036] (2) Concentrate the extract under reduced pressure at 60°C for 2 hours to remove ethanol to obtain the extract, measure the relative density of the supernatant of the extract to be 1.25, then add water to the supernatant of the extract and stir continuously, while using the specific gravity Meter measurement, until obtaining relative density is the medicinal extract dilution of 1.10, then above-mentioned medicinal extract dilution is ultrafiltered by the ultrafiltration tube that molecular weight cut off is 3000, and the relative density of the medicinal ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com