Efficient sieve plate carbonating tower with liquid phase as continuous phase

A technology of carbonation tower and sieve plate, which is applied in the direction of chemical method for reacting liquid and gas medium, carbonate preparation, chemical instrument and method, etc., and can solve the problem that high-efficiency trays are not applicable and easy to accumulate crystallization and scarring , tower fluid axial back-mixing and other issues, to achieve light weight, simple structure, and solve the effect of axial back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A high-efficiency sieve plate carbonation tower with the liquid phase as the continuous phase, comprising a tower body 1, a liquid inlet and a gas outlet are arranged at the top of the tower body 1, and in the tower body 1, from top to There are several sieve plates 3 with low opening ratios provided with downcomers 2. The sieve plates 3 have a porosity rate of 0.3-2.5%. There is a certain gap between two adjacent sieve plates. The diameter of the sieve hole on the plate 3 is 10-30mm; since the gas composition and volume in the tower are in the process of changing, the opening ratio, sieve hole diameter and sieve hole diameter of the sieve plate 3 from top to bottom in the tower body 1 The number is variable, wherein the two downcomers 2 are located at the edge of the sieve plate 3 .

Embodiment 2

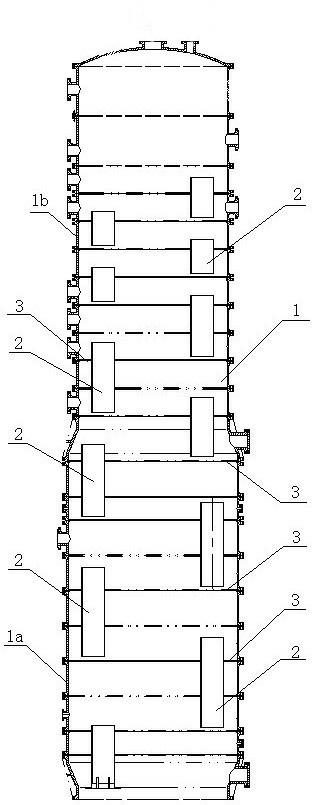

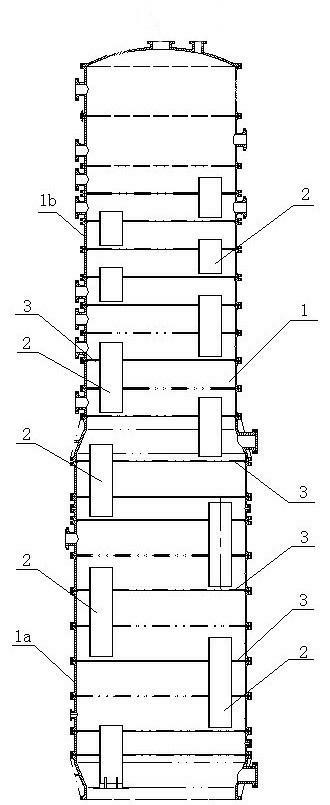

[0022] Embodiment 2: in ammonia alkali method alkali making, such as figure 1 As shown, a high-efficiency sieve plate carbonation tower with the liquid phase as the continuous phase includes a tower body 1, and a liquid inlet and a gas outlet are arranged on the top of the tower body 1. The tower body 1 is a different-diameter tower body. The diameter of the middle part 1a of the body is 3400mm, and the diameter of the upper part 1b of the tower body is 3000mm; in the tower body 1, 12 low-opening sieve plates 3 with two downcomers 2 are arranged from top to bottom, The opening ratio of the sieve plate 3 is 1.2-2.2%, there is a certain gap between two adjacent sieve plates, and the diameter of the sieve hole on the sieve plate 3 is 16-30mm, because the gas composition and volume in the tower are different In the process of changing, the opening rate, sieve hole diameter and sieve hole number of the sieve plate 3 from top to bottom in the tower body 1 change, and its opening rat...

Embodiment 3

[0024] Embodiment 3: In the soda production by combined alkali method, a kind of high-efficiency sieve plate carbonation tower with liquid phase as the continuous phase comprises a tower body 1, and a liquid inlet and a gas outlet are arranged at the top of the tower body 1, and the tower body 1 is a different-diameter tower body, the diameter of the middle part of the tower body is 2800mm, and the diameter of the upper part of the tower is 2500mm. In the tower body 1, there are 13 low openings with two downcomers 2 from top to bottom. rate sieve plate 3, the opening rate of the sieve plate 3 is 0.3-0.8%, there is a certain gap between two adjacent sieve plates, and the diameter of the sieve hole on the sieve plate 3 is 10-16mm, due to the The gas composition and volume are all in the process of changing. The opening ratio, diameter and number of sieve holes of the sieve plate 3 from top to bottom in the tower body 1 change, and the opening ratio and sieve diameter are within t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com