Method for controlling chlorine dioxide in desalting system based on ORP monitoring

A chlorine dioxide and control method technology, applied in chemical instruments and methods, general water supply saving, water/sewage multi-stage treatment, etc., can solve problems such as cumbersome operation, loss, and affecting the personal safety of testers, so as to improve safety , to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

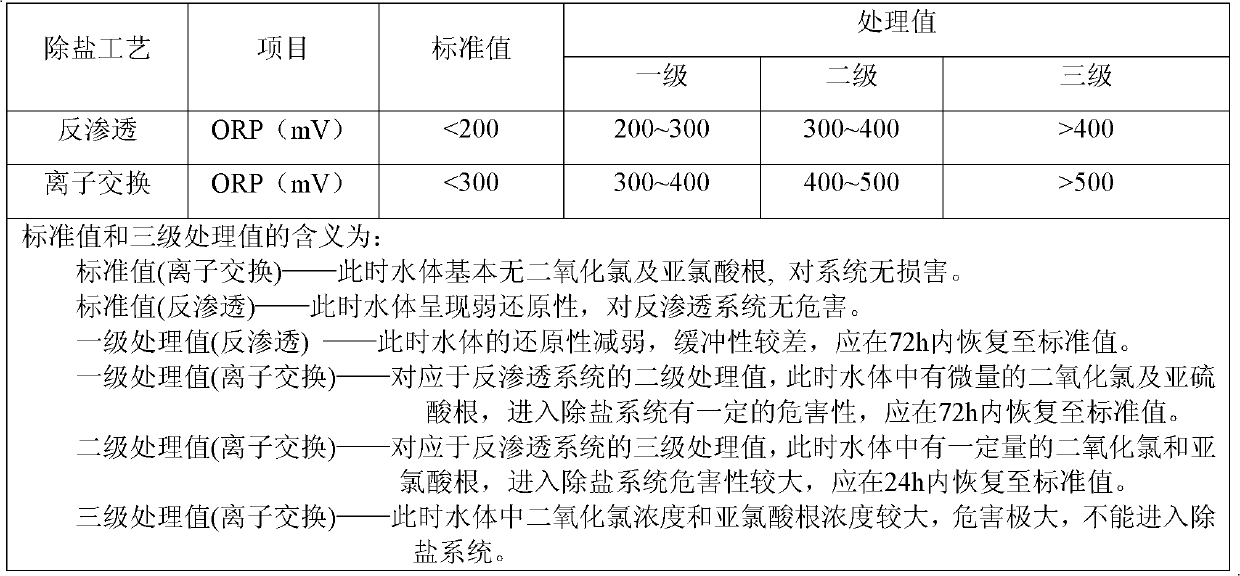

Embodiment 1

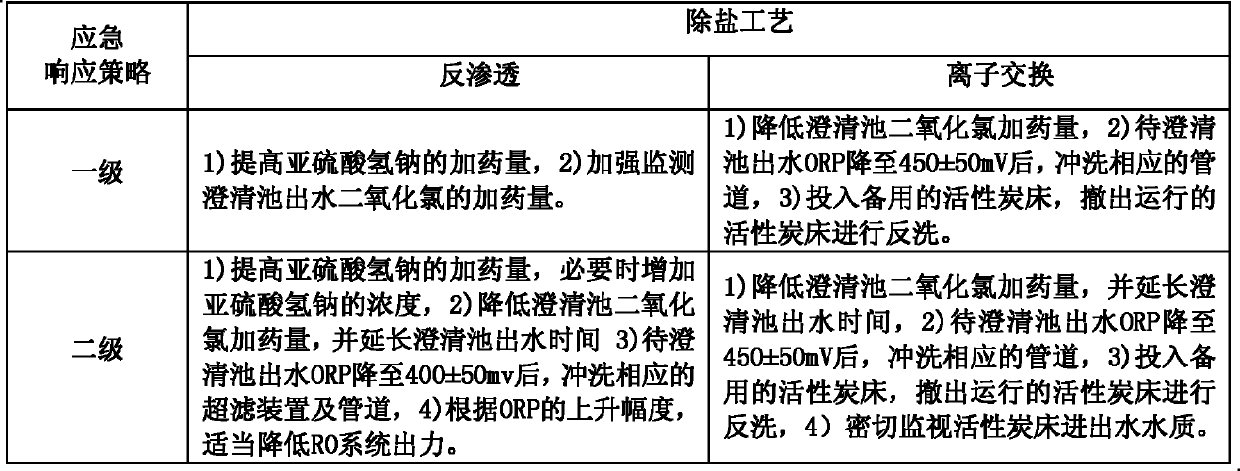

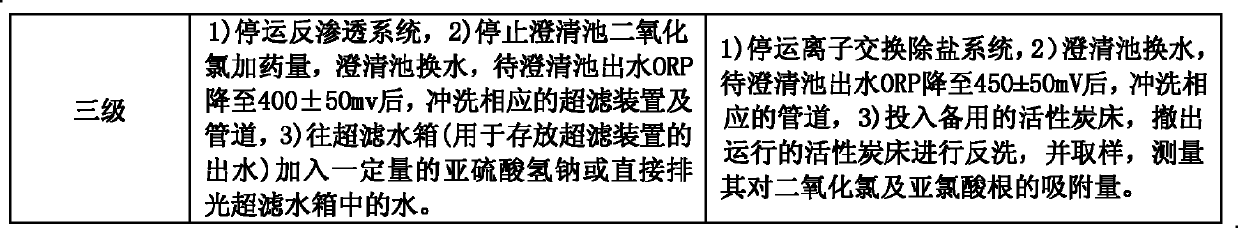

[0023] For the ion exchange system, when the ORP is 420mV, it can be seen from the control standard that the water quality of the water body is within the range of the secondary treatment value, and there is a certain risk. At this time, the following measures are taken according to Table 2 to make the water quality Return to normal: 1) Reduce the amount of chlorine dioxide dosing in the clarification tank and prolong the water outlet time of the clarification tank; 4) Closely monitor the quality of the influent and effluent water of the activated carbon bed. The actual monitored chlorine dioxide concentration parallel test results were 0mg / L and 0.08mg / L, mainly due to the low detection limit of manual analysis.

Embodiment 2

[0025] For the reverse osmosis desalination system, when the ORP is 350mV, compared with the control standard, it can be seen that the water quality of the water body is within the range of the secondary treatment value, and there is a certain risk. At this time, take the following measures according to Table 2. To restore water quality to normal: 1) increase the dosage of sodium bisulfite (for example, 5mg / L), increase the concentration of sodium bisulfite if necessary (for example, increase to 20%), 2) reduce the dosage of chlorine dioxide in the clarifier 3) After the ORP of the clarifier effluent drops to 400±50mv, flush the corresponding ultrafiltration device and pipeline, 4) According to the increase of ORP, appropriately reduce the output of the RO system. The actual monitored chlorine dioxide concentration parallel test results were 0mg / L and 0.08mg / L, mainly due to the low detection limit of manual analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com