Huperzine A high-producing strain and method for producing huperzine A by fermenting same

A high-yield technology for huperzine A, applied in fermentation, fungi, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

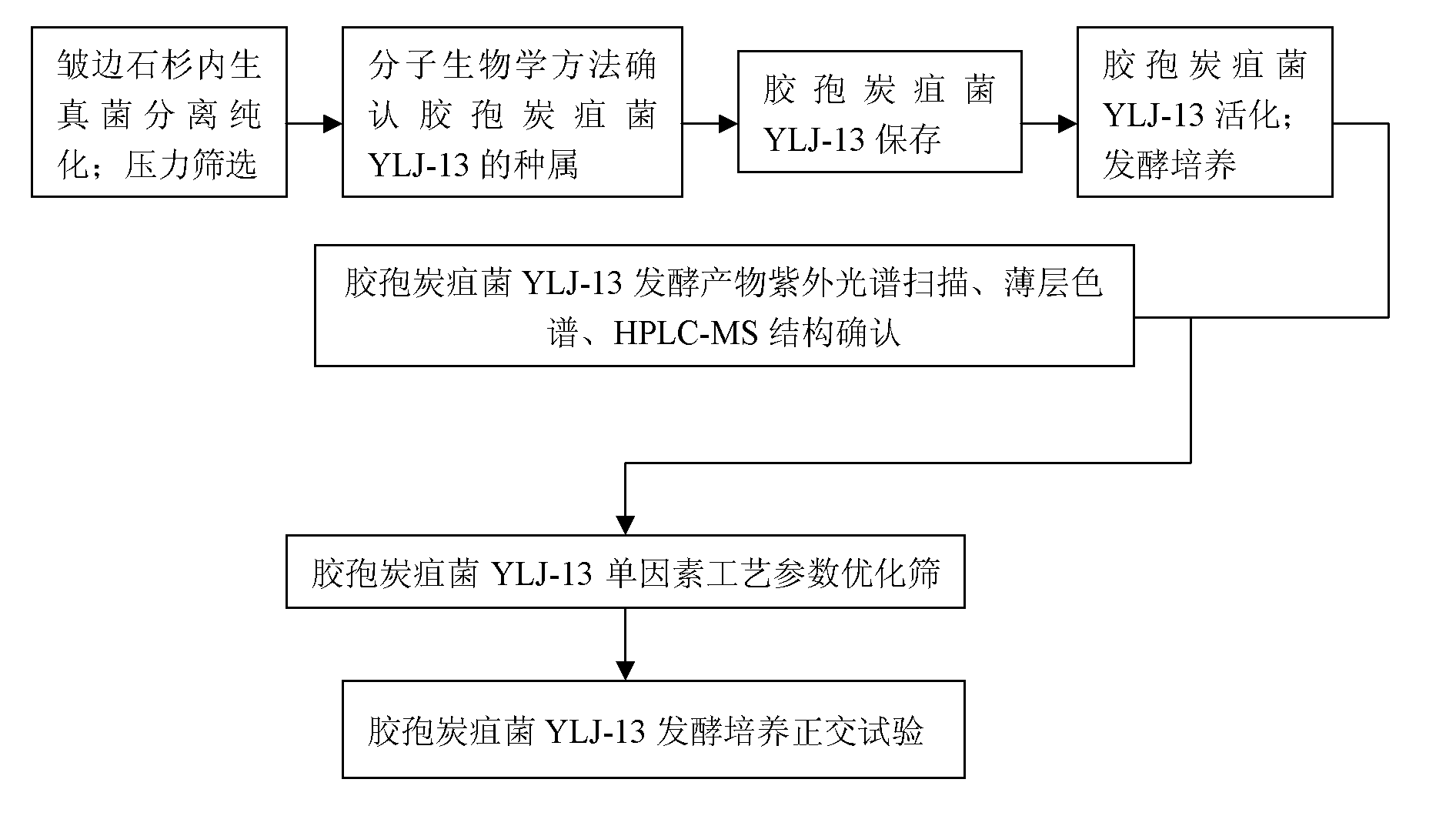

Method used

Image

Examples

Embodiment 1

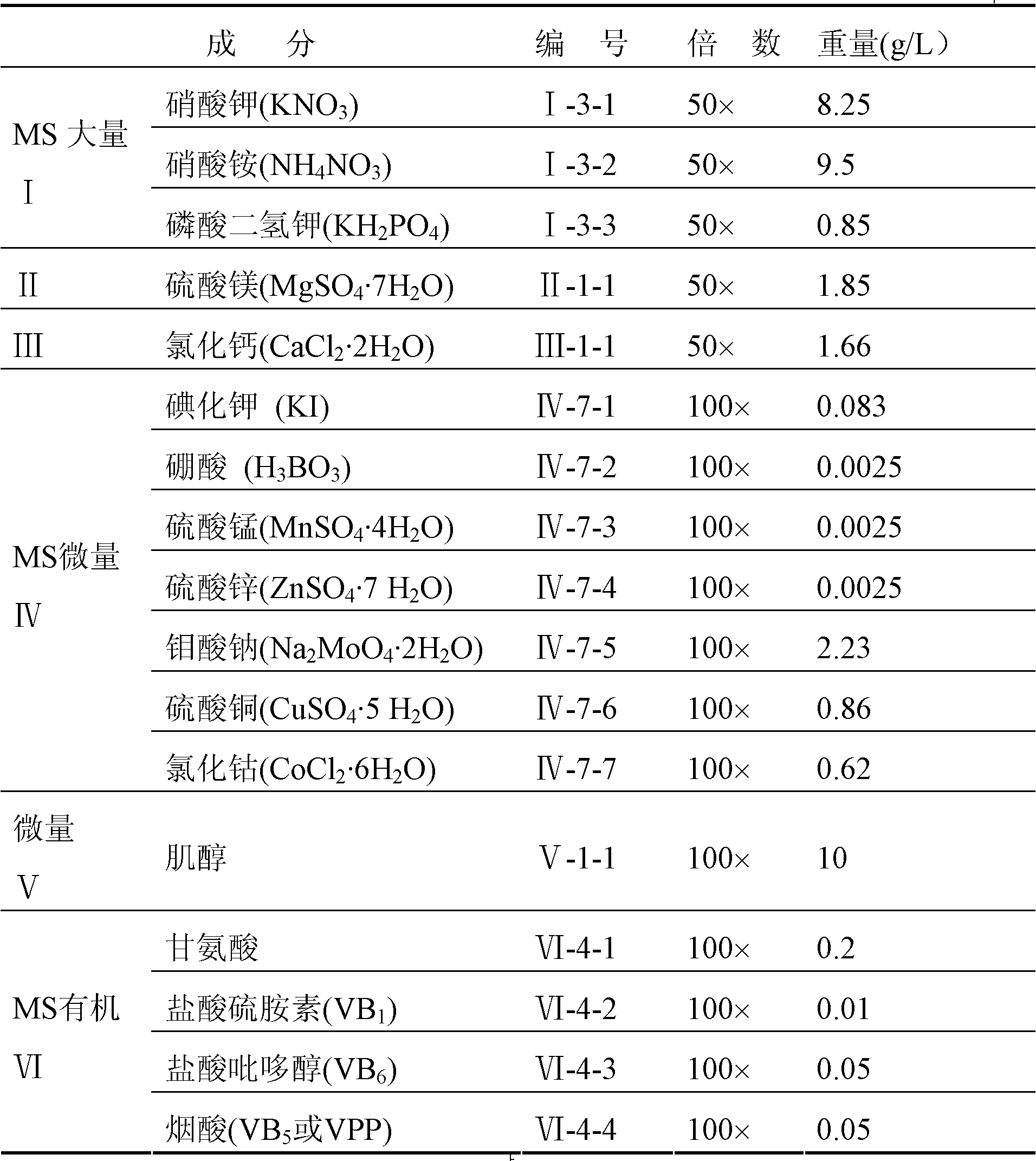

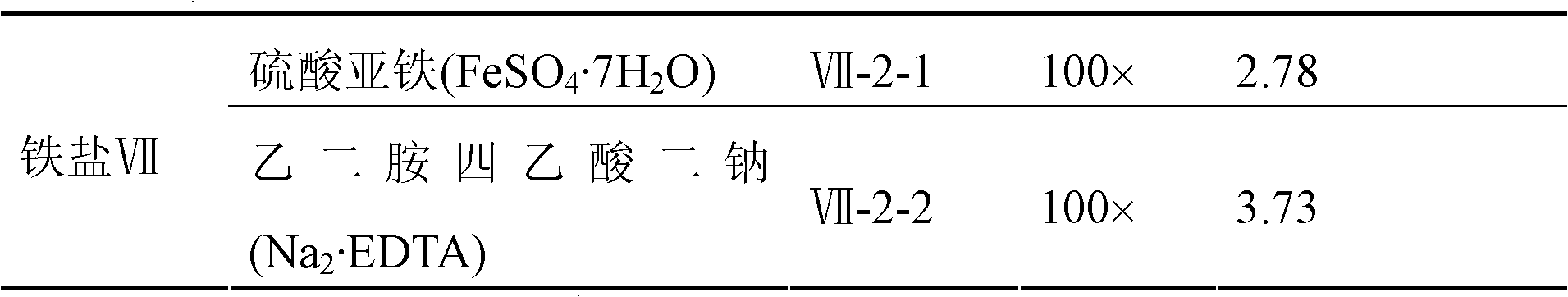

[0048] Examples of the present invention are shown below. These examples are not intended to limit the scope of the invention. Example 1, Orthogonal method to determine the optimal culture conditions for the production of Huperzine A by fermentation of G. glyospora YLJ-13

[0049] On the basis of the initial medium, 10-30g of sucrose was added to each liter of potato liquid culture system, the speed of the shaker was 100-150r / min, and the culture was shaken at a constant temperature of 24-34°C for 3-7 days, and the huperzine A in the fermentation liquid was determined. accumulated amount.

[0050] Table 2 Orthogonal test header

[0051]

[0052] Table 3 Orthogonal test design table and results

[0053]

[0054] Table 4 Orthogonal test results analysis table

[0055]

[0056] The results of orthogonal test analysis show that:

[0057] (1) The best ratio for the fermentation of this strain is A 2 B 2 C 3 D. 2 , that is, the dosage of sucrose is 20g / L, the cultu...

Embodiment 2

[0059] Embodiment 2, shaking flask fermentation produces huperzine A:

[0060] 1. Culture medium and strains

[0061] Bacterial classification: glyospora anthracnose YLJ-13 of the present invention;

[0062] Preservation and activation medium on slant: improved PDA medium;

[0063] Fermentation medium: improved potato liquid medium;

[0064] 2. Fermentation culture

[0065] Fermentation culture condition: the bacterial classification activated of the present invention is got mycelium, inoculates 0.01% mycelium by weight in 5L fermentation bottle, and pH value is natural value (5.80), ferments under the following conditions:

[0066] Sucrose dosage: 100g

[0067] Shaker temperature: 29℃±1℃

[0068] Speed: 130 rpm

[0069] Fermentation cycle: 96 hours

[0070] The fermentation results are as follows: filter the mycelium, obtain the filtrate, vacuumize and concentrate under reduced pressure to obtain the fermentation concentrate, and analyze the target substance and Huperz...

Embodiment 3

[0072] Embodiment 3, the enlarged fermentation production of huperzine A:

[0073] 1. Culture medium and strains

[0074] Bacterial classification: glyospora anthracnose YLJ-13 of the present invention;

[0075] Preservation and activation medium on slant: improved PDA medium;

[0076] Fermentation medium: improved potato liquid medium;

[0077] 2. Fermentation culture

[0078] Fermentation culture condition: the bacterial classification activated of the present invention is got mycelium, adds 0.01% mycelia by weight in 100L fermented liquid, in fermenter, pH value is natural value (5.80), ferments in following condition:

[0079] Sucrose dosage: 2000g

[0080] Tank temperature: 29℃±1℃

[0081] Air volume: 1:0.4

[0082] Speed: 100 rpm

[0083] Tank pressure: 0.04Mpa

[0084] Fermentation cycle: 115 hours ± 5 hours

[0085] The fermentation result is as follows: filter the mycelia, obtain the filtrate, vacuumize and concentrate under reduced pressure to obtain the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com