Double-layered jacquard home textile fabric with perspective effect and manufacture method thereof

A double-layer jacquard and printing technology, which is applied in the direction of textile, dyeing, and patterned fabrics, etc., can solve the problems of labor-consuming, long process cycle, hand feeling, comfort, low washing shrinkage, and low appearance, which does not meet the requirements for the use of bedding fabrics, etc. problem, to achieve a good decorative effect, soft feel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

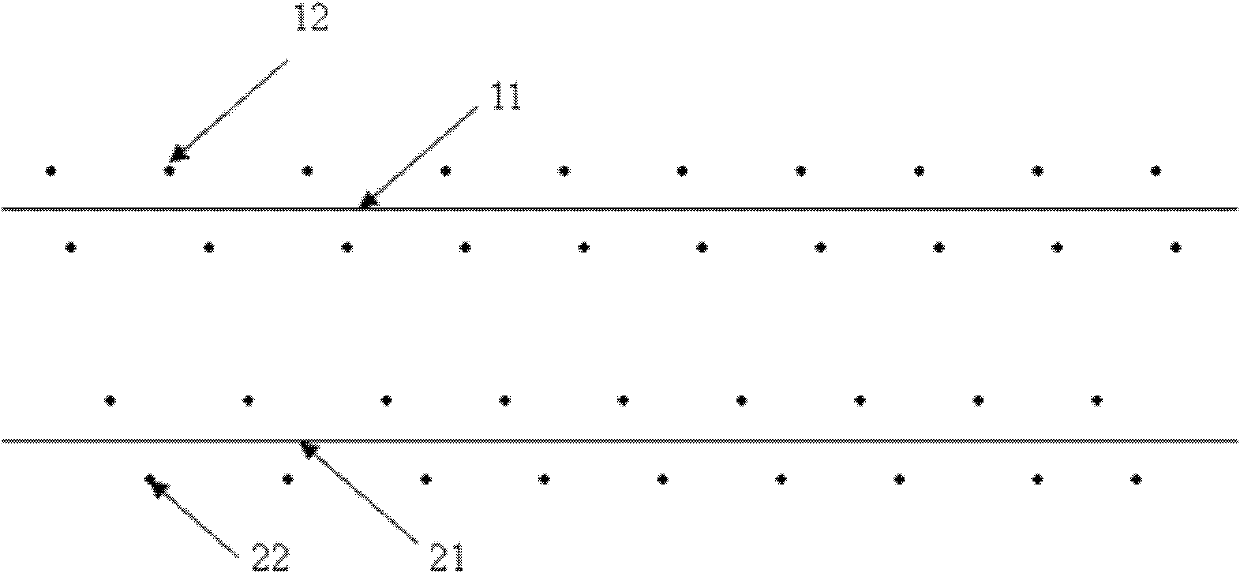

[0020] The embodiment discloses a double-layer jacquard fabric with a see-through effect and a processing method thereof.

[0021] The processing technology of the double-layer jacquard fabric with see-through effect is: warping→weaving→washing and drying→presetting→washing→softening→setting.

[0022] It selects the weaving yarn through the design of the double-layer fabric structure. In this embodiment, the white polyester or nylon monofilament with a light triangular cross-section and a yarn count of 20-30D is selected as the upper warp yarn, the upper weft yarn and the lower warp yarn. Colored regenerated cellulose fiber yarn with a yarn count of 16S~40S, colored cotton yarn or colored blended yarn blended from regenerated cellulose fiber and cotton fiber is used as the lower weft yarn, and then the fabric is made according to the designed double-layer fabric structure. The weaving of gray cloth interweaves the upper warp yarn and the upper weft yarn to form the upper weave...

Embodiment 2

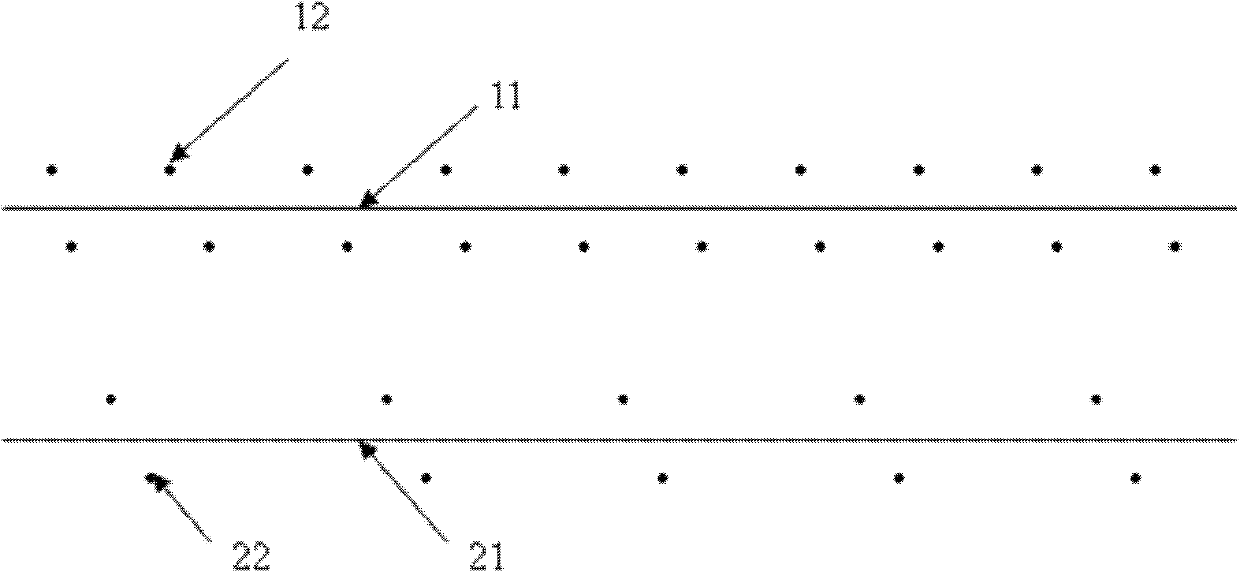

[0030] The embodiment discloses a double-layer jacquard printed fabric with a see-through effect and a processing method thereof.

[0031] The processing technology of the double-layer jacquard printed fabric with see-through effect is: warping→weaving→washing→bleaching→printing→soaping→softening→drying→setting.

[0032]It is similar to the process of Example 1, except that when selecting the weaving yarn, the weft yarn of the lower layer is made of white yarn, that is, the weft yarn of the lower layer is made of white regenerated cellulose fiber yarn, white cotton yarn or blended by regenerated cellulose fiber and cotton fiber. into a white blended yarn. Therefore, after the fabric gray cloth is woven, reactive printing treatment needs to be carried out on the reverse side of the fabric. In order to ensure a good reactive printing effect, bleaching treatment is generally carried out before the reactive printing treatment process.

[0033] For warp 30D nylon monofilament Nylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com