Textile product with weight losing function and preparation method thereof

A technology of textile products and functions, which is applied in the field of textile products with weight-loss function and its preparation, which can solve the problems of restraining the body and the body’s weight-loss effect is not fundamentally achieved, and achieve good effect, speed up body metabolism, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

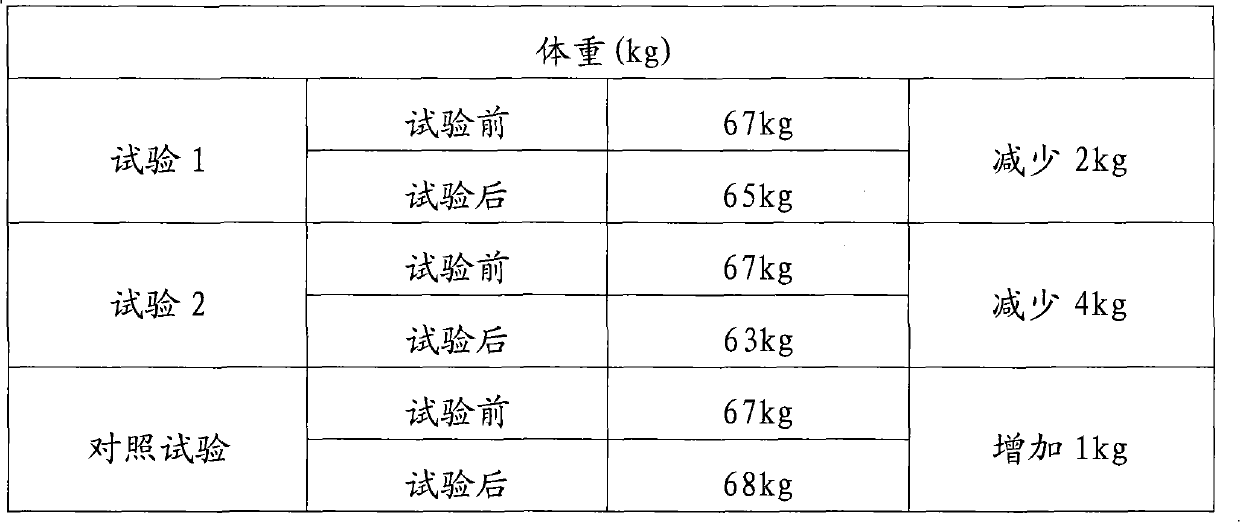

Examples

Embodiment 1

[0026] Step 10: After mixing the rare earth, far-infrared powder, negative oxygen ion powder and germanite powder, add polyethylene as a catalyst, the mixture of the rare earth, far-infrared powder, negative oxygen ion powder and germanite powder is calculated by weight percentage Including 25% of rare earth, 40% of far infrared powder, 23% of negative oxygen ion powder and 12% of germanite powder, the rare earth includes 25% of yttrium, 35% of cerium and 40% of holmium , the addition of the polyethylene accounted for 5% by weight of the mixture of rare earth, far infrared powder, negative oxygen ion powder and germanite powder;

[0027] Step 20: put the polyethylene-added mixture into a gravure printing machine and react at 60° C. for 50 minutes;

[0028] Step 30: Spray the reacted material evenly on the textile through a spraying machine, so that the reacted material penetrates into the textile, spray for 20 minutes until the reacted material can no longer penetrate the text...

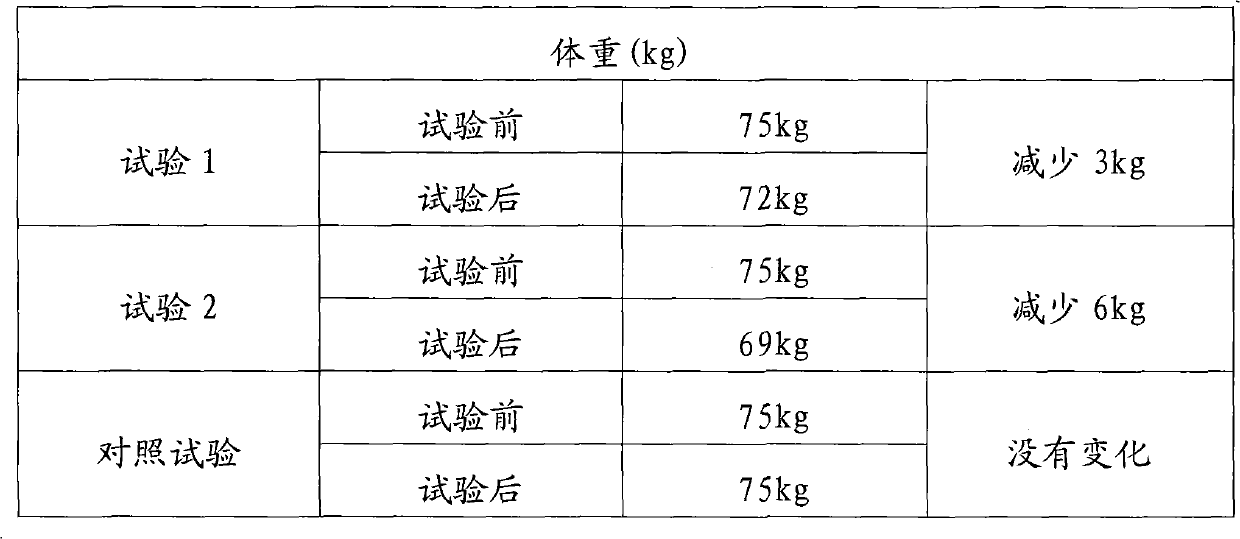

Embodiment 2

[0032] Step 10: After mixing the rare earth, far-infrared powder, negative oxygen ion powder and germanite powder, add polypropylene as a catalyst, the mixture of the rare earth, far-infrared powder, negative oxygen ion powder and germanite powder is calculated by weight percentage Including 55% of rare earth, 10% of far infrared powder, 7% of negative oxygen ion powder and 28% of germanite powder, the rare earth includes 45% of yttrium, 20% of cerium and 35% of holmium by weight percentage , the addition of polypropylene accounts for 10% by weight of the mixture of rare earth, far-infrared powder, negative oxygen ion powder and germanite powder;

[0033] Step 20: put the polypropylene-added mixture into a gravure printing machine and react at 280° C. for 30 minutes;

[0034] Step 30: Spray the reacted material evenly on the textile through a spraying machine, so that the reacted material penetrates into the textile, and spray for 40 minutes until the reacted material can no l...

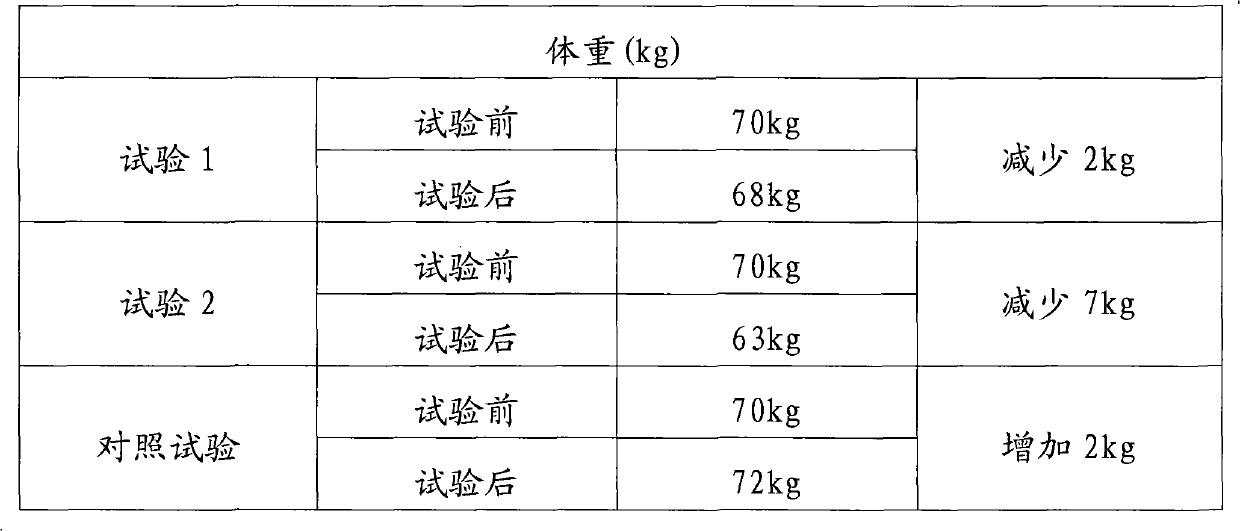

Embodiment 3

[0038] Step 10: After mixing the rare earth, far-infrared powder, negative oxygen ion powder and germanite powder, add polystyrene as a catalyst, the mixture of the rare earth, far-infrared powder, negative oxygen ion powder and germanite powder is based on its weight percentage It includes 45% of rare earth, 20% of far infrared powder, 20% of negative oxygen ion powder and 15% of germanite powder, and the rare earth includes 30% of yttrium, 30% of cerium and 40% of Holmium, the addition of polystyrene accounts for 7% by weight of the mixture of rare earth, far-infrared powder, negative oxygen ion powder and germanium stone powder;

[0039] Step 20: put the polystyrene-added mixture into a gravure printing machine and react at 200°C for 40 minutes;

[0040] Step 30: Spray the reacted material evenly on the textile through a spraying machine, so that the reacted material penetrates into the textile, spray for 30 minutes until the reacted material can no longer penetrate the tex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com