Oscillatory type tidal power generation device

A tidal current power generation and oscillating technology, which is applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems that tidal current oscillating power generation technology has not yet made actual progress, and achieve simple structure, high reliability and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

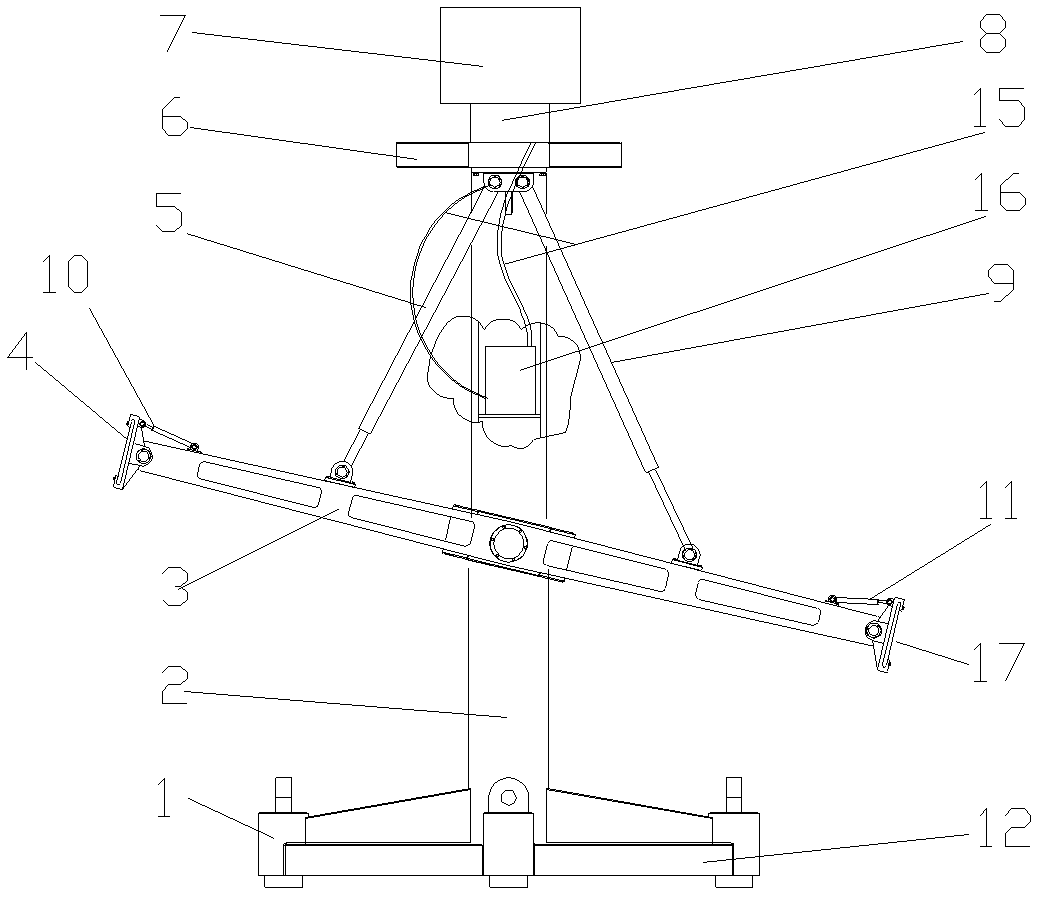

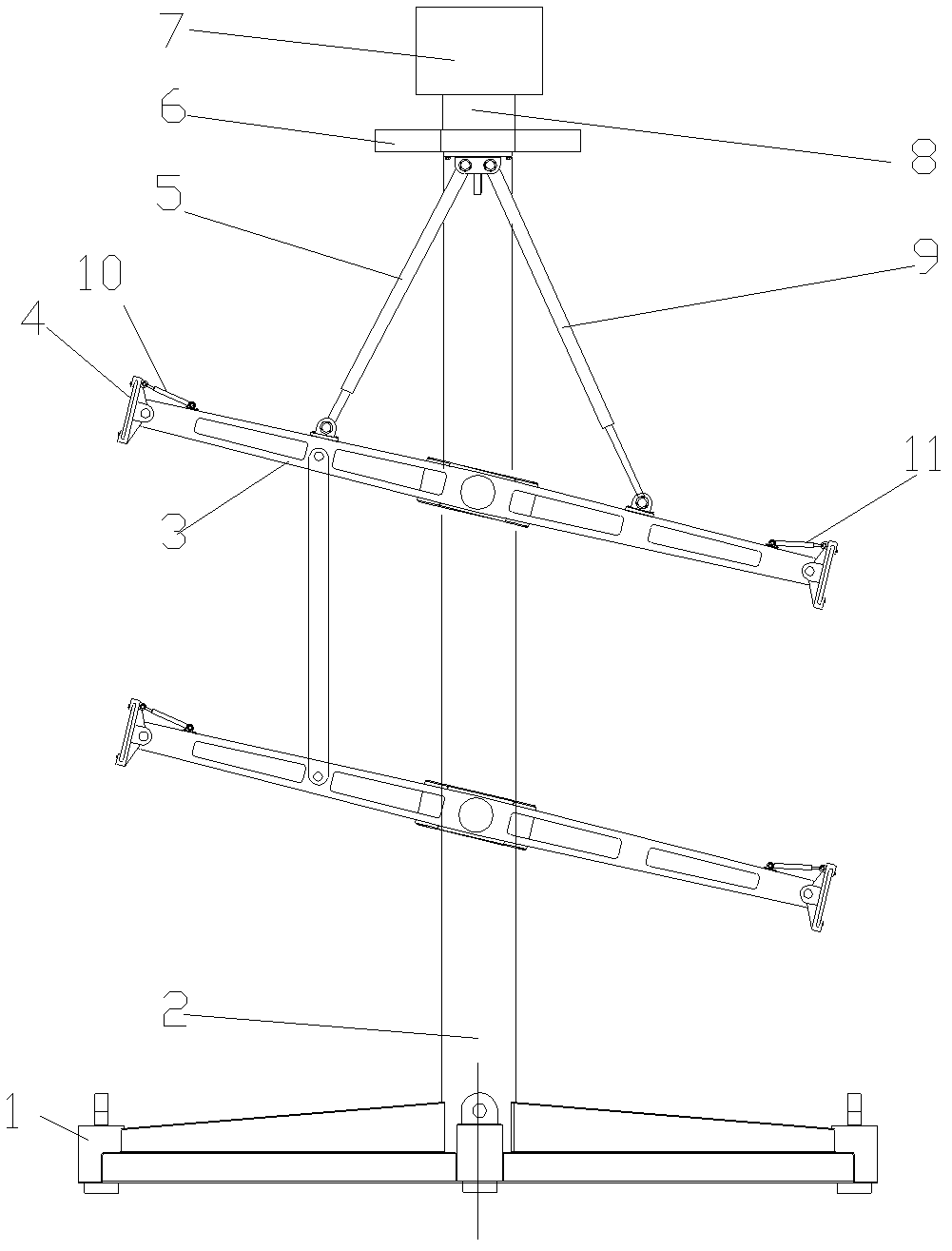

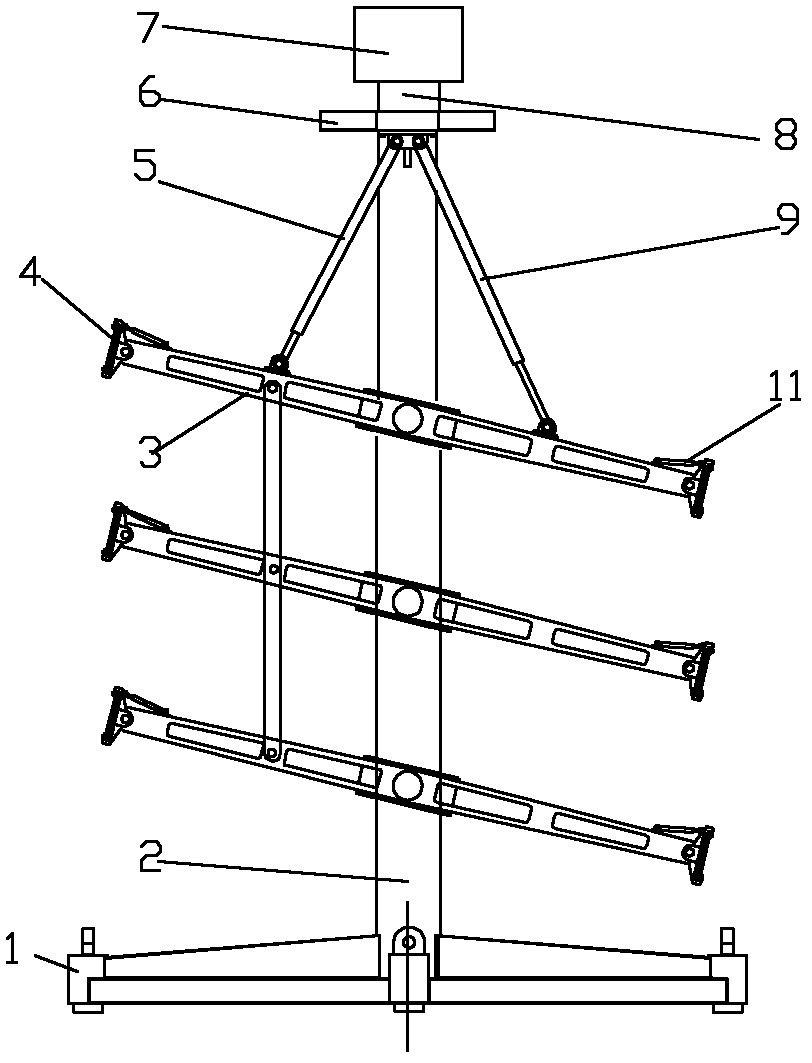

[0022] Such as figure 1 As shown, the oscillating tidal current power generation device of the present invention includes a base 12, a base adjustment cylinder 1, a column 2, a tidal current energy absorbing plate 4, a hydraulic accumulator 16, a power generation cylinder 5, a generator 7, a power generation hydraulic motor 8, a power generation Oil cylinder 9 and energy-absorbing plate angle adjustment oil cylinder 10. The column 2 is installed on the base 12, and the base 12 is equipped with at least one vertically placed base adjustment oil cylinder 1 ( figure 1 There are four in the middle), and the adjustment of the base adjustment oil cylinder 1 ensures that the column 2 stands vertically on the seabed. At least one swing arm 3 is installed on the column 2, the middle part of the swing arm 3 is hinged with the column 2 through a rotating shaft, and the swing arm 3 can swing around the rotating shaft. When there are two or more swing arms 3, each swing arm 3 is connecte...

Embodiment 2

[0026] Such as Figure 4 As shown, this embodiment is to figure 1 The power generation cylinder 5 and the power generation cylinder 9 in the given embodiment 1 are replaced by a swing cylinder 14, and the tidal current energy absorbing plate 4 and the tidal current energy absorbing plate 17 at both ends of the swing arm 3 are installed on the swinging cylinder 13 and the swinging cylinder 18 respectively. both ends of arm 3.

[0027] The tidal current energy-absorbing plate 4 and the tidal current energy-absorbing plate 17 oscillate up and down while compressing the swing oil cylinder 14 to output high-pressure oil. Swing oil cylinder 14 can be sealed in the column 2, is not corroded by sea water.

[0028] Compared with the impeller energy-absorbing technology, the size of the energy-absorbing plates 4 and 17 of the oscillating tidal current energy-absorbing device of the present invention is not limited in the horizontal direction; in the vertical direction, as the water de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com