Pendulum bob-constant section beam fiber bragg grating dip angle sensor and calibration method

An inclination sensor and fiber grating technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of large temperature influence, low measurement accuracy, and large volume, and achieve good stability, high measurement accuracy, and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

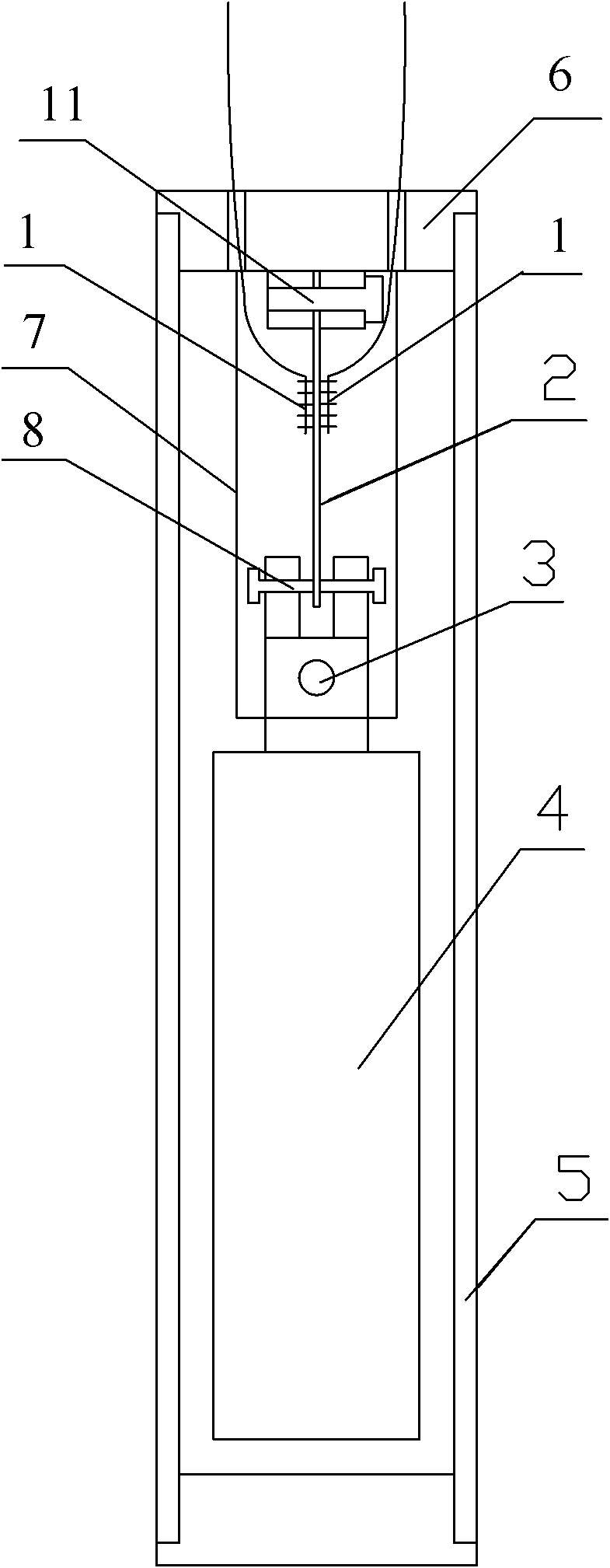

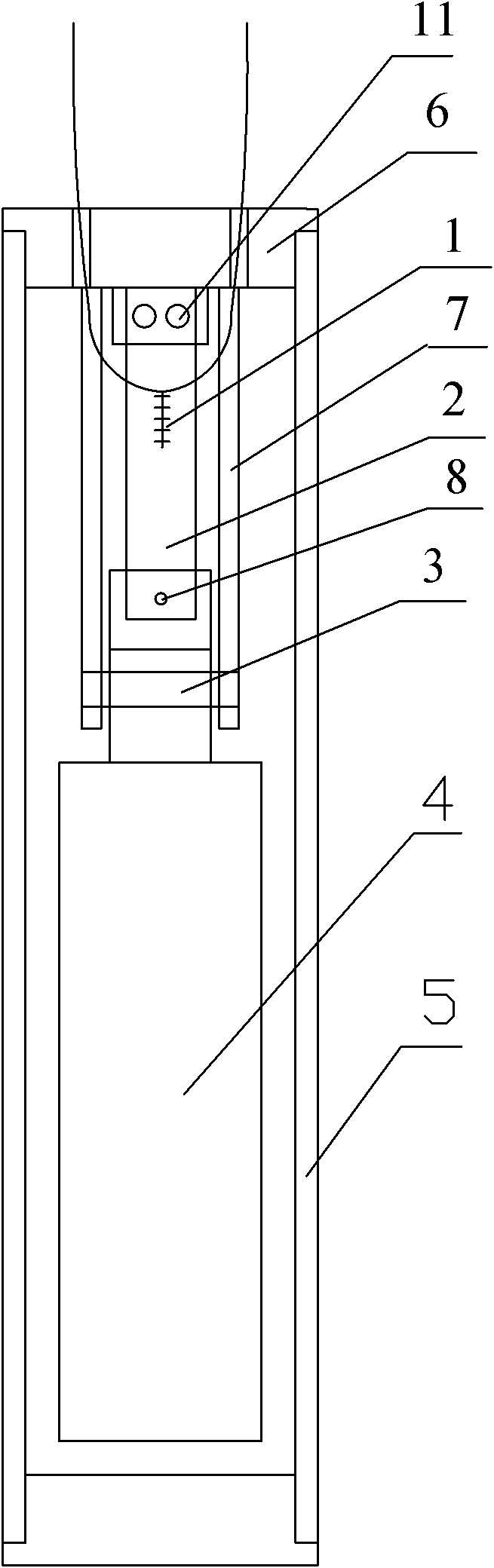

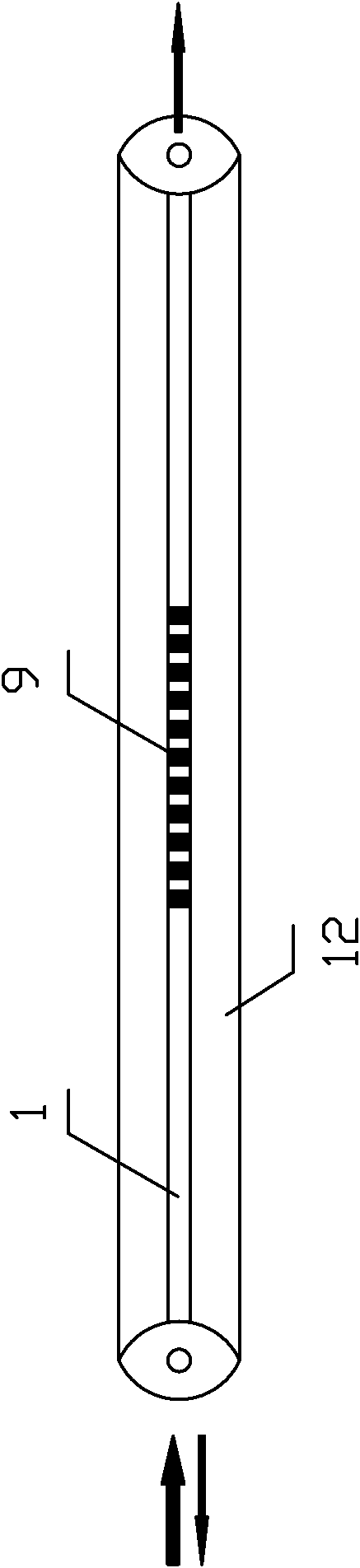

[0040] A pendulum-equal section beam fiber optic grating inclination sensor, comprising: a positioning seat 6, a pendulum 4, an equal section beam 2, an optical fiber grating 1, and a connecting sleeve 7, one end of the connecting sleeve 7 is fixedly connected to the positioning seat 6 On, the other end is hinged with one end of the pendulum 4 through the first hinge shaft 3; the cross-section of the constant-section beam 2 is rectangular and is inserted into the connecting sleeve 7, and one end thereof is fixedly connected to the positioning On the seat 6, the other end is connected to the pendulum 4 through the second hinge shaft 8; the first hinge shaft 3 and the second hinge shaft 8 are perpendicular to each other; the fiber grating 1 has two pieces, which are respectively fixedly installed on the Referring to the two opposite sides of the constant-section beam 2 , the two opposite sides of the constant-section beam 2 refer to the sides corresponding to the longer side in t...

Embodiment 2

[0047] A pendulum-equal-section beam fiber optic grating inclination sensor is that a sleeve 5 is arranged outside the positioning seat 6, the pendulum 4, the equal-section beam 2, the fiber grating 1, and the connecting sleeve 7 described in embodiment 1. The positioning seat 6 is fixedly installed on one end of the sleeve 5 .

[0048] The calibration method of the pendulum-equal cross-section beam fiber grating inclination sensor prepared in embodiment 1 or embodiment 2 of the present invention is as follows:

[0049] The first step: Prepare an I-shaped simply supported beam, a fiber grating sensor network analyzer, a dial gauge, and a level; one end of the simply supported beam is hinged on the hinge shaft, and the other end is supported by a jack support;

[0050] Step 2: Adjust the axis of the I-shaped simply supported beam to the level with a level ruler, and then paste the pendulum-equal-section beam FBG inclination sensor on the surface of the beam, so that the pendul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com