Method for filing and displaying coupling screwed torsion graph in real time

A real-time display and graphics technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of slow display of trend control, scattered data, inconvenient use, etc., to facilitate backup and transfer, and improve screwing efficiency , Ease of production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in conjunction with accompanying drawing and embodiment:

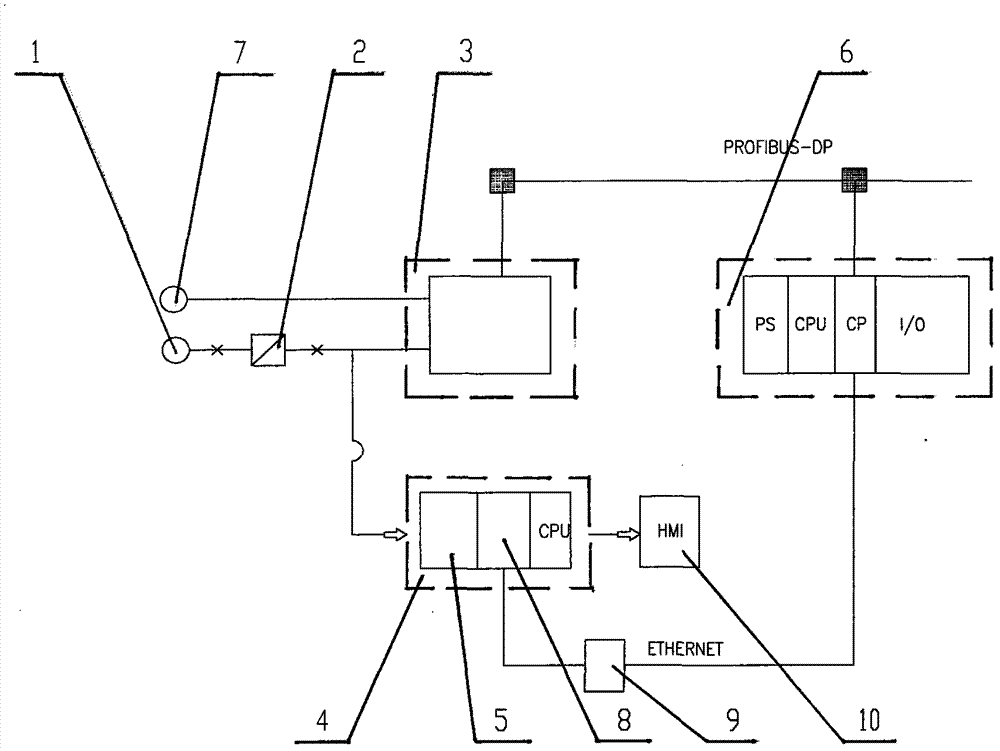

[0011] Such as figure 1 As shown, a method for real-time display and archiving of coupling torque graphics, force sensor 1 (model such as Z7AD1 / 10T of HBM Company) and transmitter 2 (model such as AE301 of HBM Company) located on the screwing machine Connection, the physical signal size of the force sensor in this embodiment is 2mv / v, the physical signal of the force sensor is converted into a standard analog signal (±10v in this example) through the transmitter 2, and the standard analog signal enters the scene PLC 3 (model such as ET200 of Siemens Company), the other is connected to the high-speed data acquisition card 5 (model such as PCI-8310) in the PCI slot of the industrial computer 4 (model such as MEC-9002 of EVOC); The analog signal is transmitted to the main PLC 6 (model such as S7-315DP2 of Siemens) through the PROFIBUS-DP network, and becomes a digital quantity th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com