Efficient permanent magnet generator with no-iron core and multiple stator

A multi-stator, ironless technology, applied in synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve the problems of increased electromagnetic force, high cost, large size, etc. The effect of output power, weight and cost reduction, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

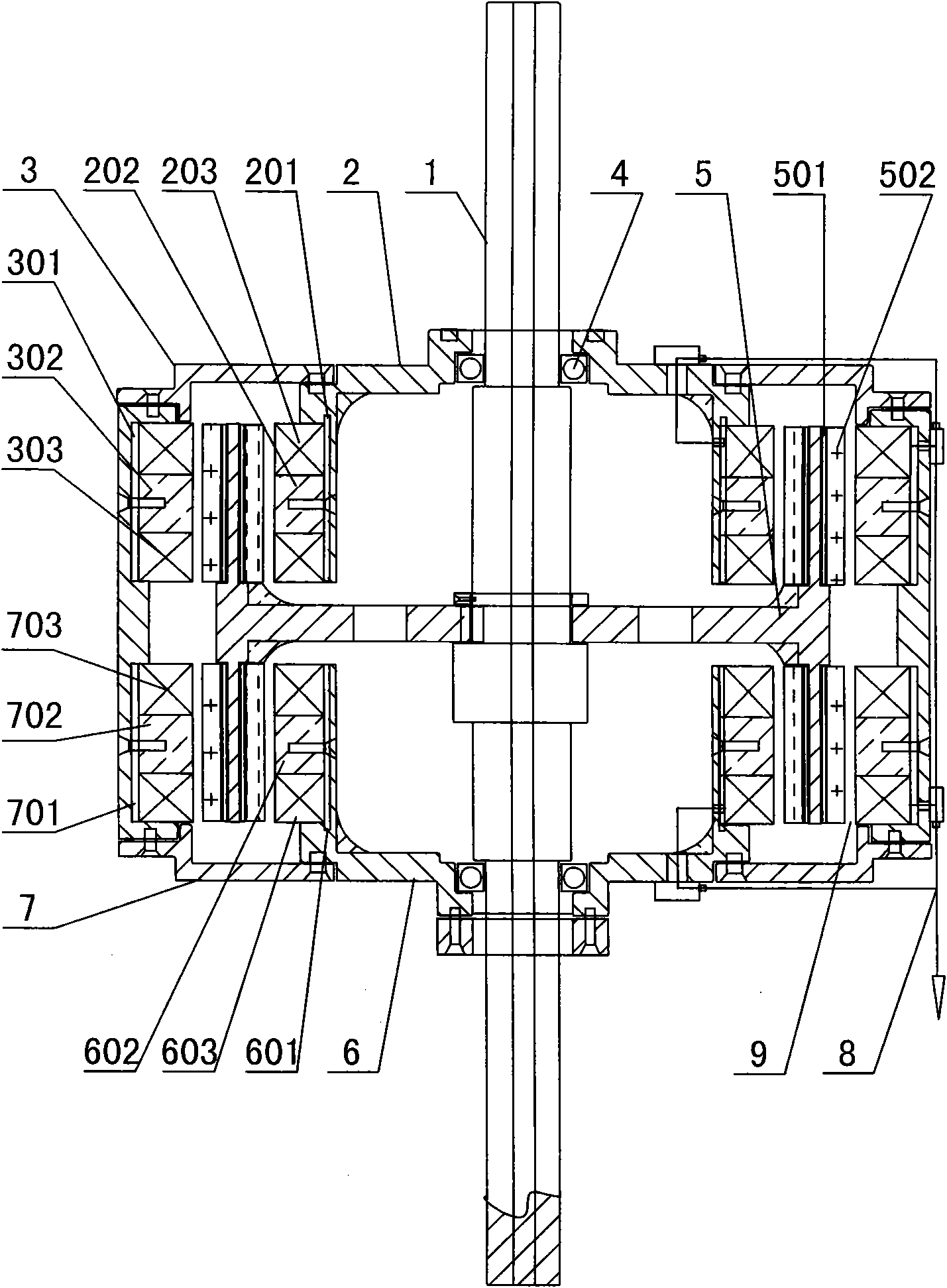

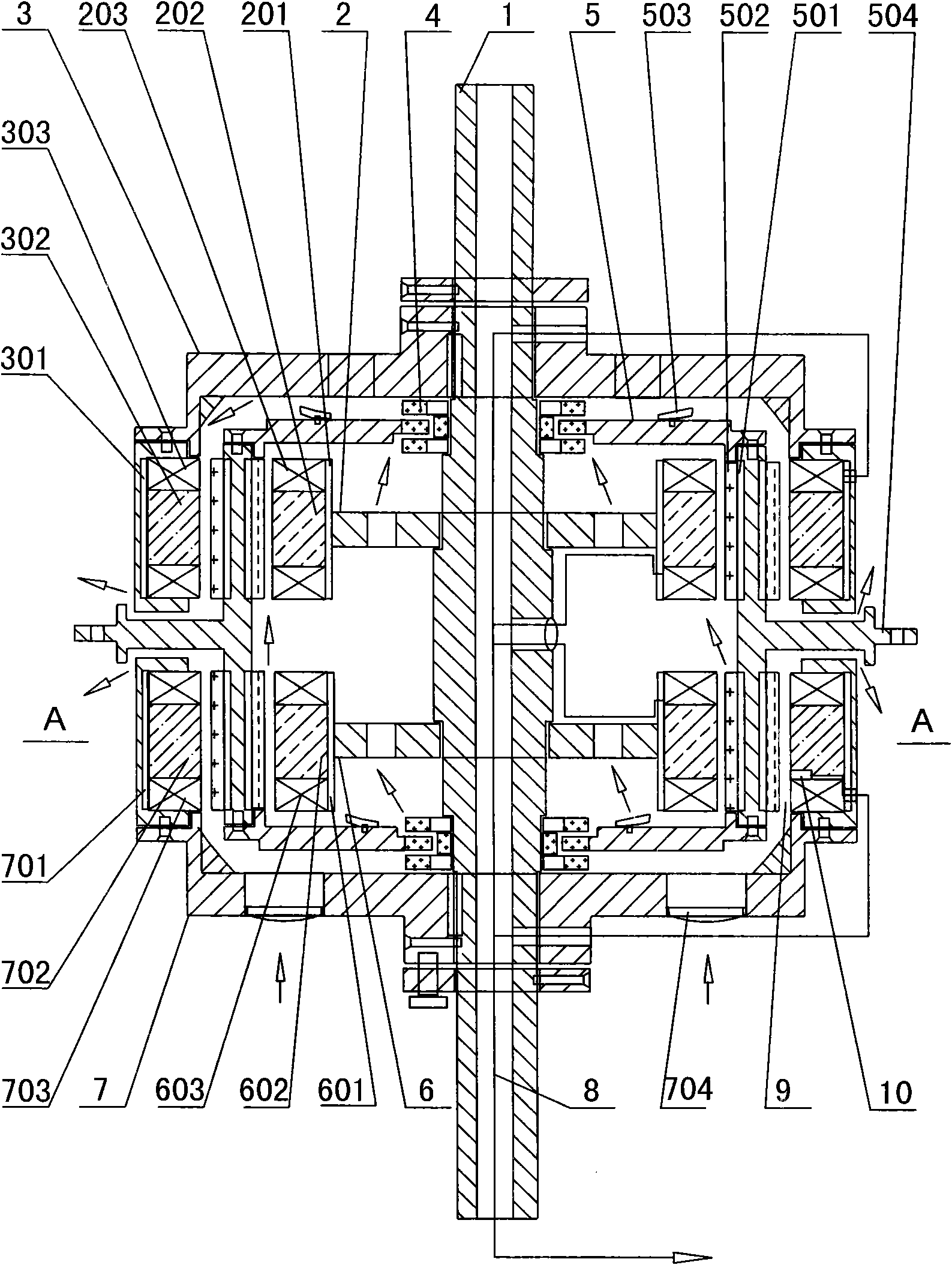

[0020] Example: attached figure 1 , a structural cross-sectional schematic diagram of an ironless multi-stator permanent magnet high-efficiency generator.

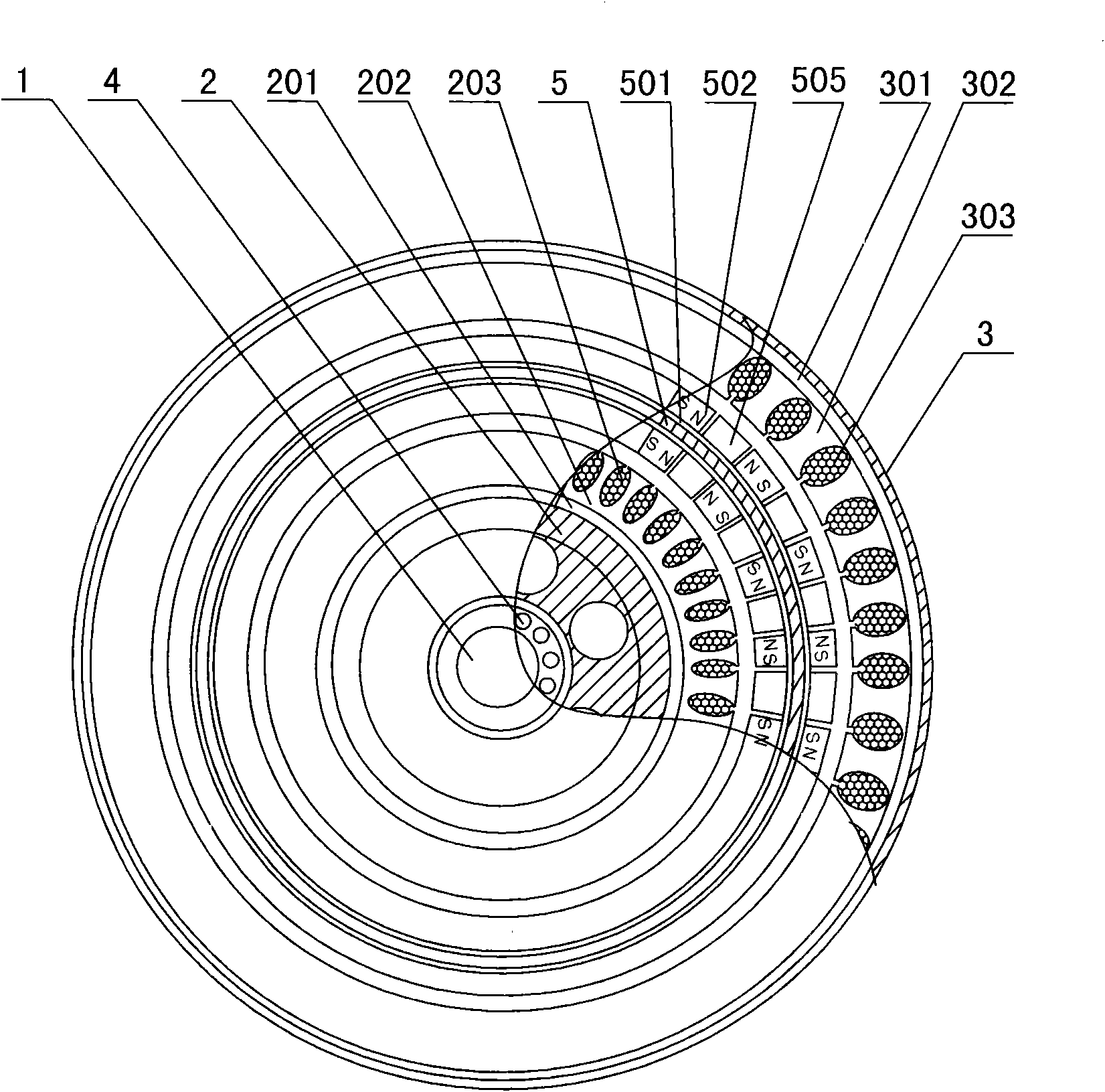

[0021] The first stator 2 and the second stator 6 are processed into a bowl-shaped shell shape, and are respectively arranged on the inside of the circumference of the rotor 5, and the main shaft 1 is supported by the bearing 4, and the wires 8 are respectively connected to the stator windings 203, 603, and pass through the inside of the shell. The pipeline leads to the junction box; the third stator 3 and the fourth stator 7 are processed into a cylindrical body, which is arranged outside the circumference of the rotor. The cylindrical body can be disassembled and processed and then fixed into one body with screws. Two sets of magnetic washers, frames, and windings are arranged along the circumferential direction, and the central round holes on both sides of the shell of the cylindrical body are respectively fixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com