Hybrid drive full-bridge synchronous rectifier

A synchronous rectifier and hybrid drive technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, high-efficiency power electronic conversion, etc., can solve the problem of high circuit cost and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

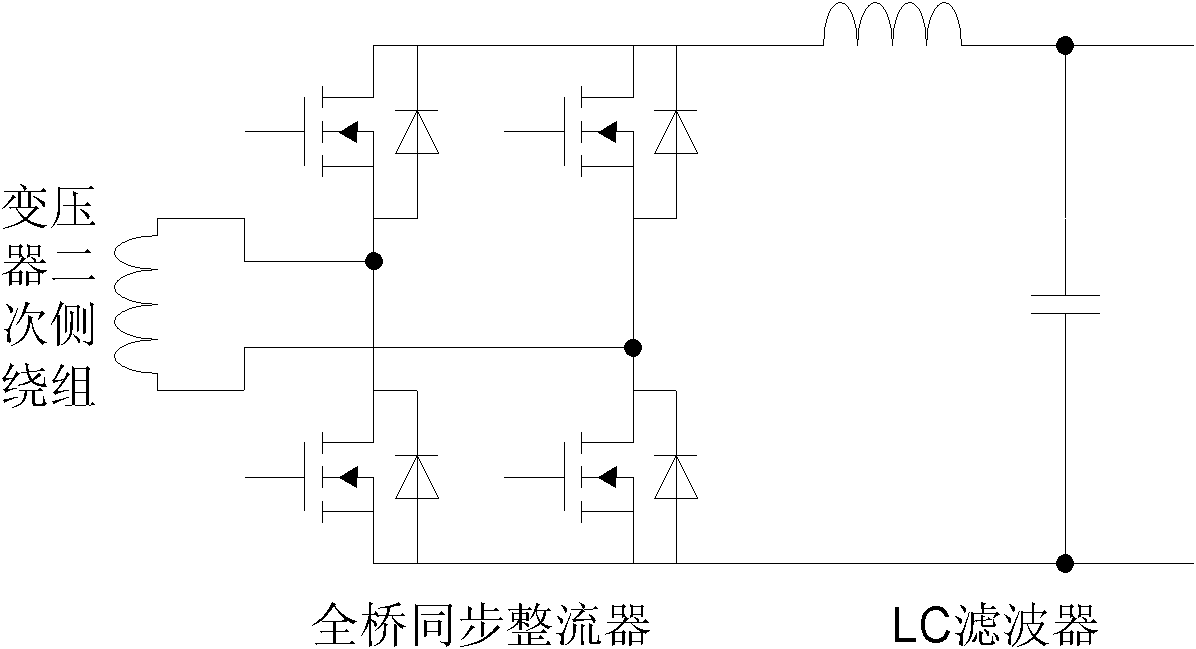

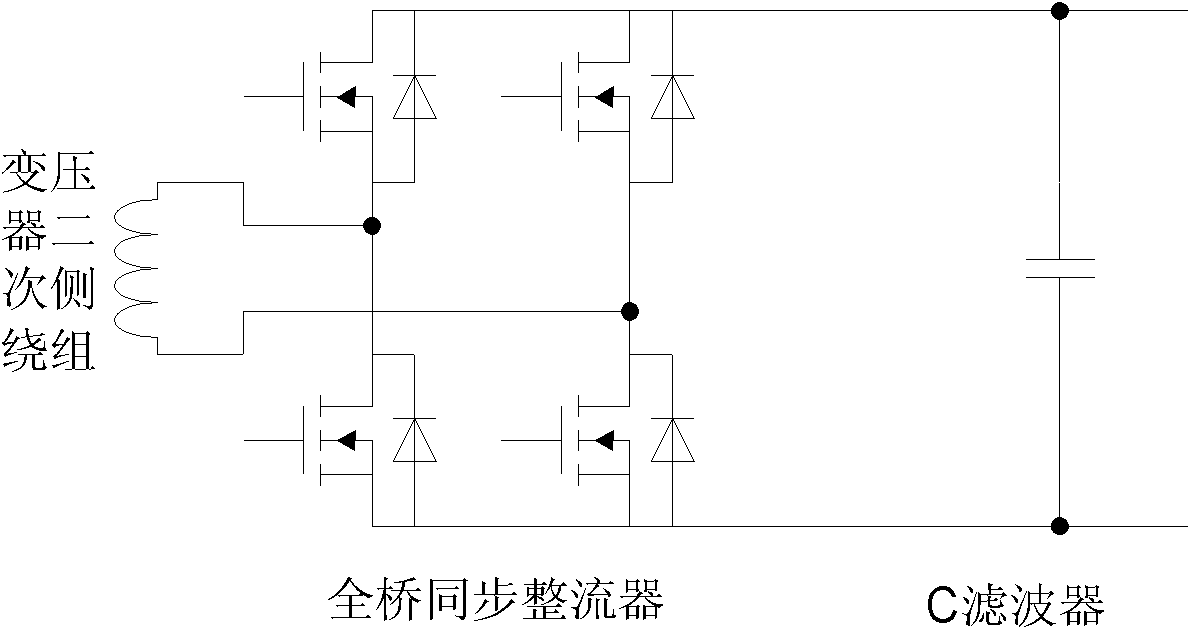

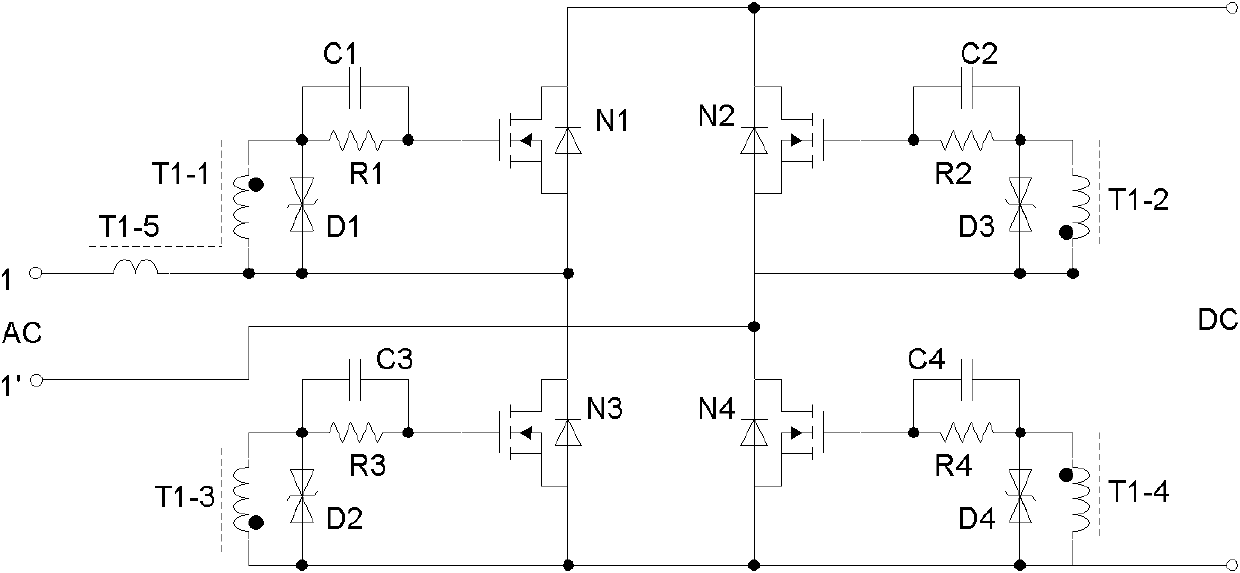

[0044] In the traditional output rectification structure, there are two types of voltage output type and current output type, such as figure 1 , 2 shown. Which type of output rectification structure to use depends on the topology of the circuit. For example, voltage-type output is suitable for traditional full-bridge PWM, phase-shifted full-bridge, half-bridge, push-pull and parallel resonance circuits, while current-type output is usually suitable for current-type push Pull, series resonance, LLC series resonance circuit, etc. Among these two types of rectifiers, synchronous rectification with a full-bridge structure requires 4 synchronous transistors and their corresponding drive circuits.

[0045] The voltage control type self-drive is applied to the voltage output type rectifier. As mentioned above, there is a situation where the current flows in the opposite direction, resulting in low light load efficiency. To solve this problem, a current detection circuit must be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com