Liquid dairy product and preparation method thereof

A dairy product and liquid technology, which is applied in the field of long shelf-life liquid dairy products, can solve the problems of high additive amount, difficult to meet, low production cost, etc., achieve good stability, reduce additive cost, and maintain the effect of flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

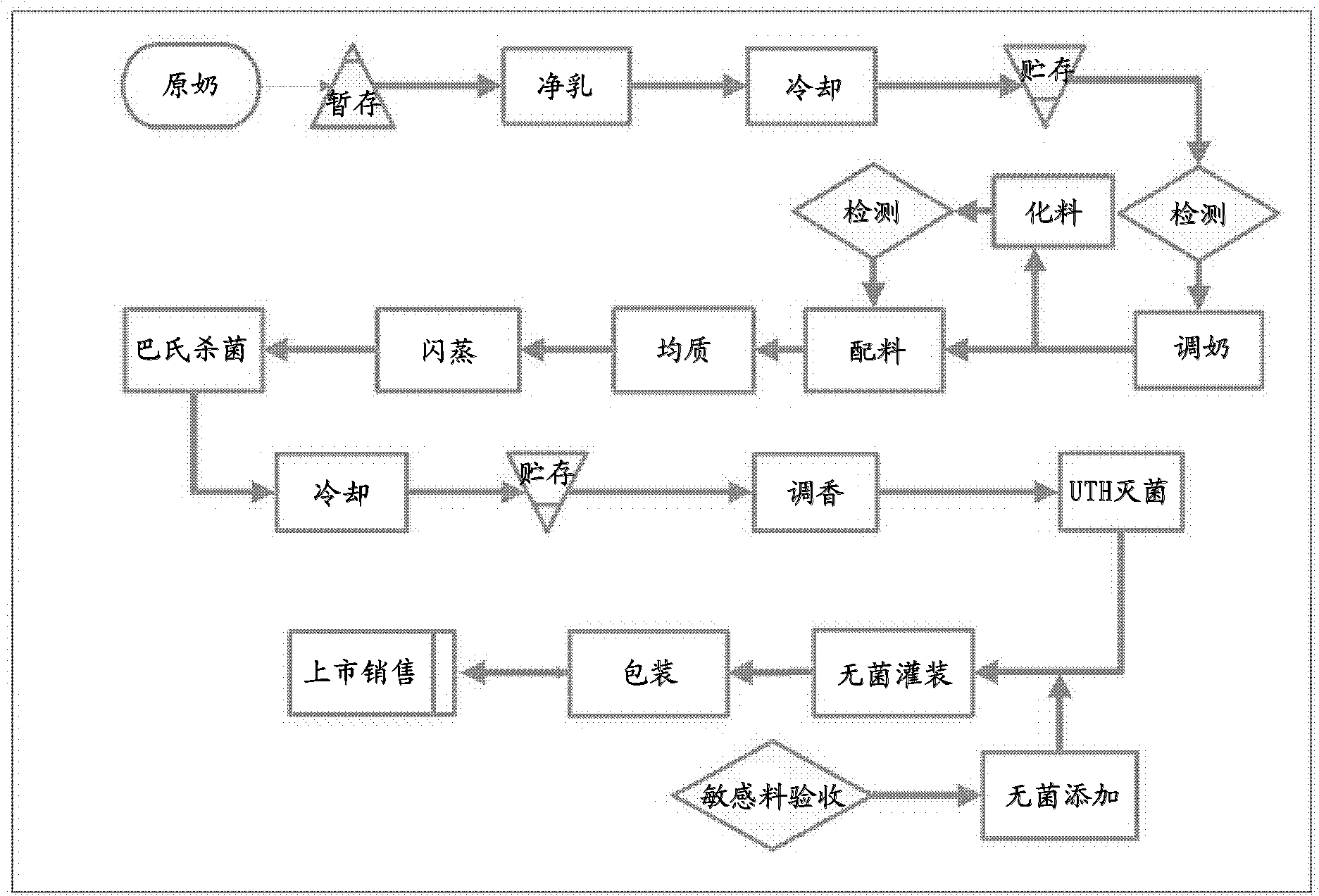

[0070] Example 1: Dairy products added with milk basic protein

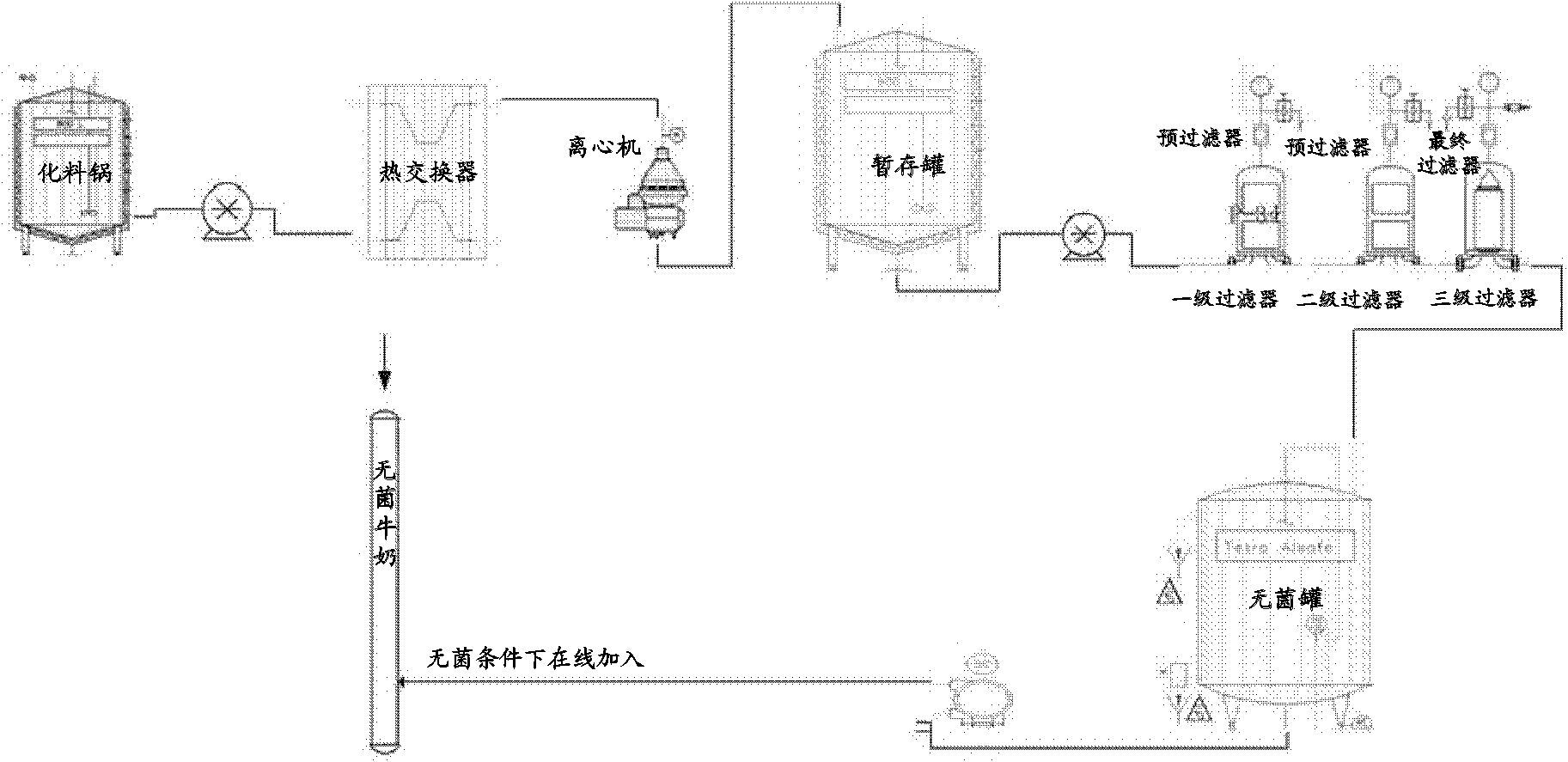

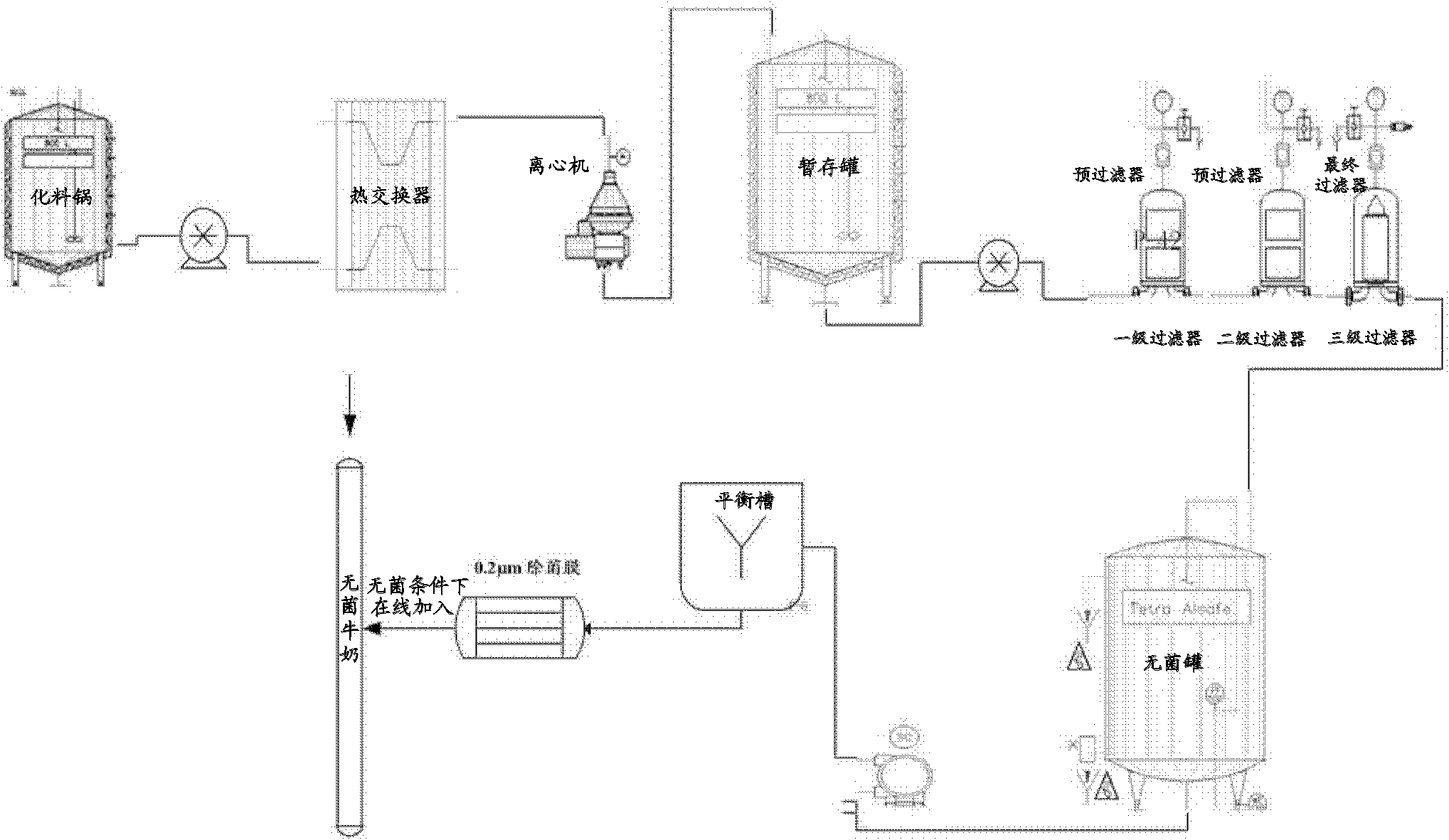

[0071] 1. Preparation process of sterile solution:

[0072] 1) Dissolution of powdery raw materials: transfer an appropriate amount of pure water into the chemical material tank, and the amount of water must be 9 times the amount of basic protein in milk. Turn on the blender, circulate the pure water between the blender and the chemical tank, raise the water temperature to 40°C~45°C, and slowly put the powdered milk alkaline protein into the blender under the condition of turning on the stirring Inside. After feeding, keep stirring for 30-40 minutes, let it stand for 30 minutes, and perform centrifugal purification after the foam is basically eliminated.

[0073] 2) Centrifugal purification: the dissolved solution is subjected to centrifugal purification treatment through a separator, the centrifugal temperature is 40±5° C., and the centrifugal acceleration a value is about 3000.

[0074] 3) Cooling of feed li...

Embodiment 2

[0096] Example 2: Dairy products added with milk basic protein

[0097] 1. Preparation process of sterile solution:

[0098] Milk basic protein aseptic liquid was prepared according to the method described in Example 1.

[0099] 2. Preparation of dairy products:

[0100] Formula (according to 1 ton):

[0101] Milk basic protein: 100 grams

[0102] Stabilizer: glyceryl monostearate 0.8 kg

[0103] The balance is milk.

[0104] Raw material standard

[0105] Raw milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%

[0106] Other raw materials are in line with national standards.

[0107] making process:

[0108] 1) Pour cold milk at 0-7°C into the batching tank.

[0109] 2) Dissolution of the stabilizer: heat up to 30°C to 35°C, and slowly add glyceryl monostearate in a stirred state. Then slowly raise the temperature to 70°C-75°C, stop heating, and continue stirring for 10-15 minutes.

[0110] 3) Homogenization: the homogenization temperature is 55°C-80°...

Embodiment 3

[0124] Example 3: Dairy products with active peptides added

[0125] 1. Preparation process of sterile solution:

[0126] The active peptide sterile solution was prepared according to the method described in Example 1.

[0127] 2. Preparation of dairy products:

[0128] Formula (according to 1 ton):

[0129] Milk: 300.0 kg; white sugar: 50.0 kg; active peptide: 10 kg; xanthan gum: 3.0 kg; propylene glycol alginate: 1.0 kg; lactic acid: 2.0 kg; citric acid: 1.8 kg; milk essence: 0.17 kg; calcium : 1.07 kg; Taurine: 0.8 kg; Isovitamin C Sodium: 0.6 kg; Purified water: make up 1000 kg.

[0130] Raw material standard

[0131] Raw milk: protein ≥ 2.95%; fat ≥ 3.0%; non-fat milk solids ≥ 8.5%

[0132] Other raw materials are in line with national standards.

[0133] making process:

[0134] 1) Pour cold milk at 0-7°C into the batching tank.

[0135] 2) Dissolution of the stabilizer: heat up to 30°C to 35°C, and slowly add glyceryl monostearate in a stirred state. Then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com