Vertical ring magnetic separator for removing iron from fly ash

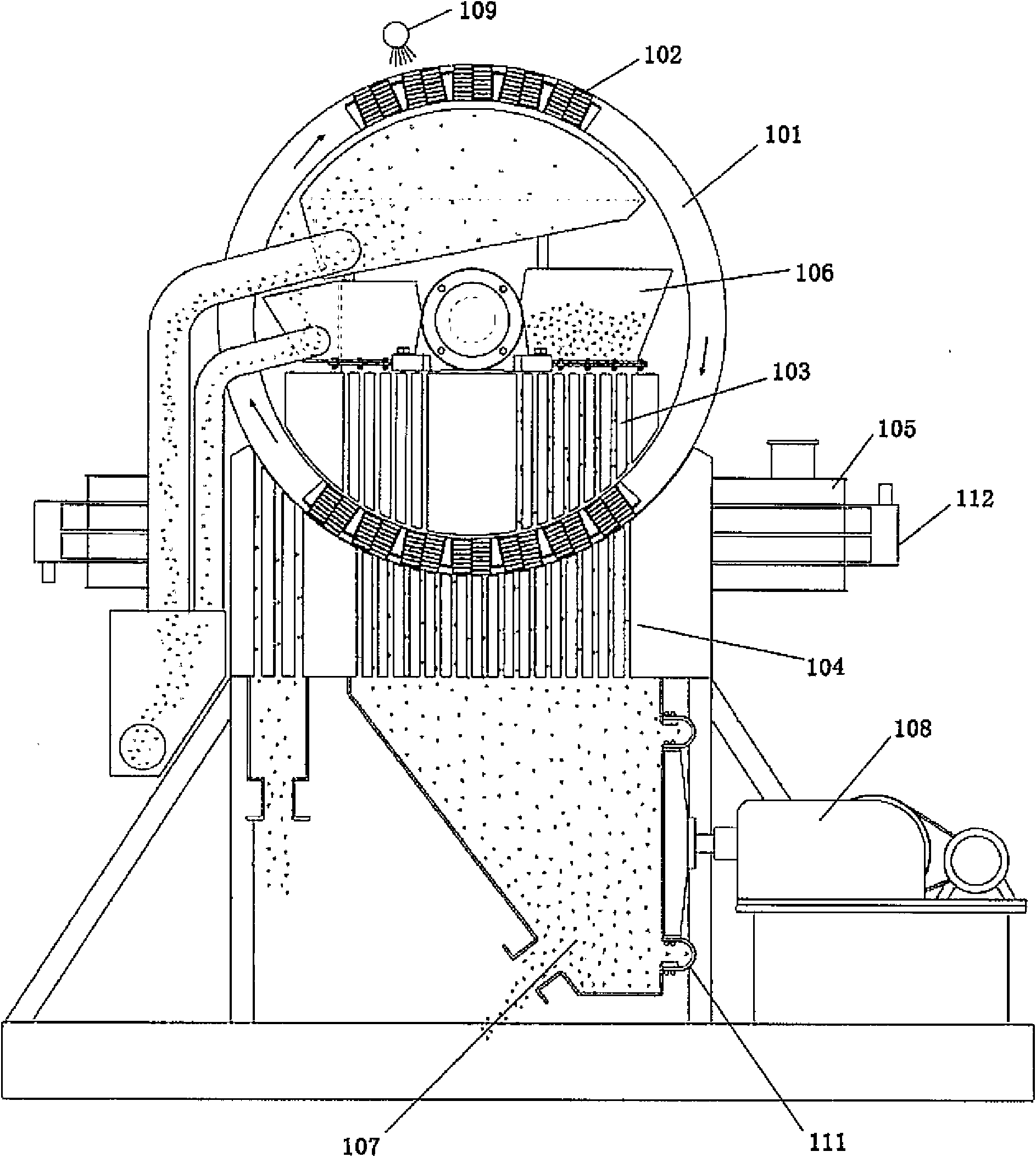

A magnetic separator and fly ash technology, applied in high gradient magnetic separators and other directions, can solve the problems of weak magnetic properties of iron minerals and reduce the effect of magnetic separation and iron removal, so as to relieve the pressure of iron removal and improve the iron removal effect. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In Embodiment 1 of the present invention:

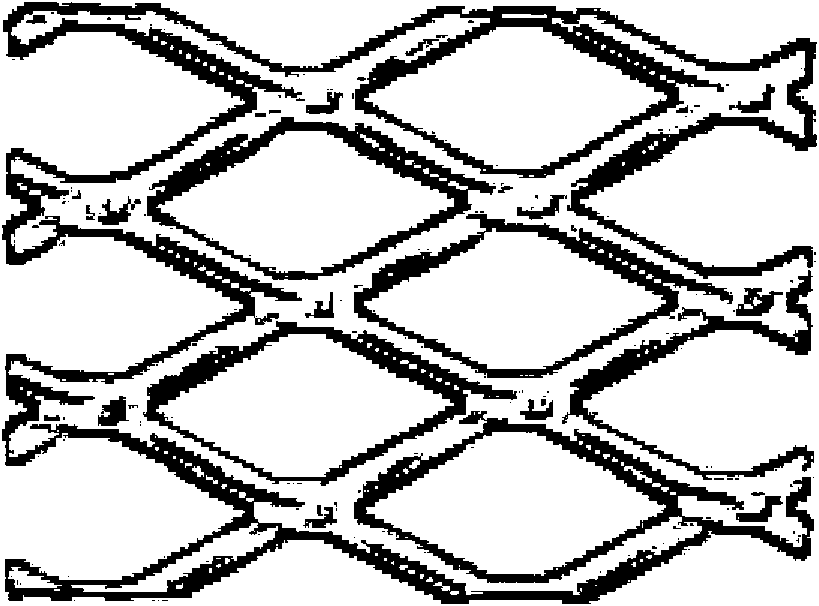

[0039] The background magnetic field strength is 12000Gs, the excitation current is 40A, the material of the steel mesh is 1Cr17, the distance between the dielectric layers of the steel mesh is 3mm, the thickness is 1mm, the grid size is 5mm×10mm, the wire stem width is 1.6mm, and the edge and corner direction is upward. At this time, the mesh The field strength of the shaped medium node can reach 22000Gs, which is 20% higher than that of the traditional vertical swivel induction wet strong magnetic separator.

Embodiment 2

[0041]The background magnetic field strength is 12000Gs, the excitation current is 40A, the material of the steel mesh is 1Cr17, the distance between the dielectric layers of the steel mesh is 2mm, the thickness is 1mm, the grid size is 3mm×8mm, the wire stem width is 1mm, and the edge direction is upward. At this time, the mesh The field strength of the dielectric node can reach 20000Gs.

Embodiment 3

[0043] The background magnetic field strength is 12000Gs, the excitation current is 50A, the material of the steel mesh is 1Cr17, the distance between the dielectric layers of the steel mesh is 5mm, the thickness is 1.5mm, the grid size is 5mm×10mm, the wire stem width is 2mm, and the edge and corner direction is upward. At this time, the mesh The field strength of the shape medium node can reach 22000Gs.

[0044] Compared with the rod-shaped medium, the surface area of the expanded mesh medium is increased by more than 5 times, the magnetic adsorption capacity is greatly increased, and the probability of magnetic substances being adsorbed is greatly increased. Moreover, the magnetic field intensity and gradient induced at the corners of the expanded mesh are also greatly improved compared with the rod-shaped medium. .

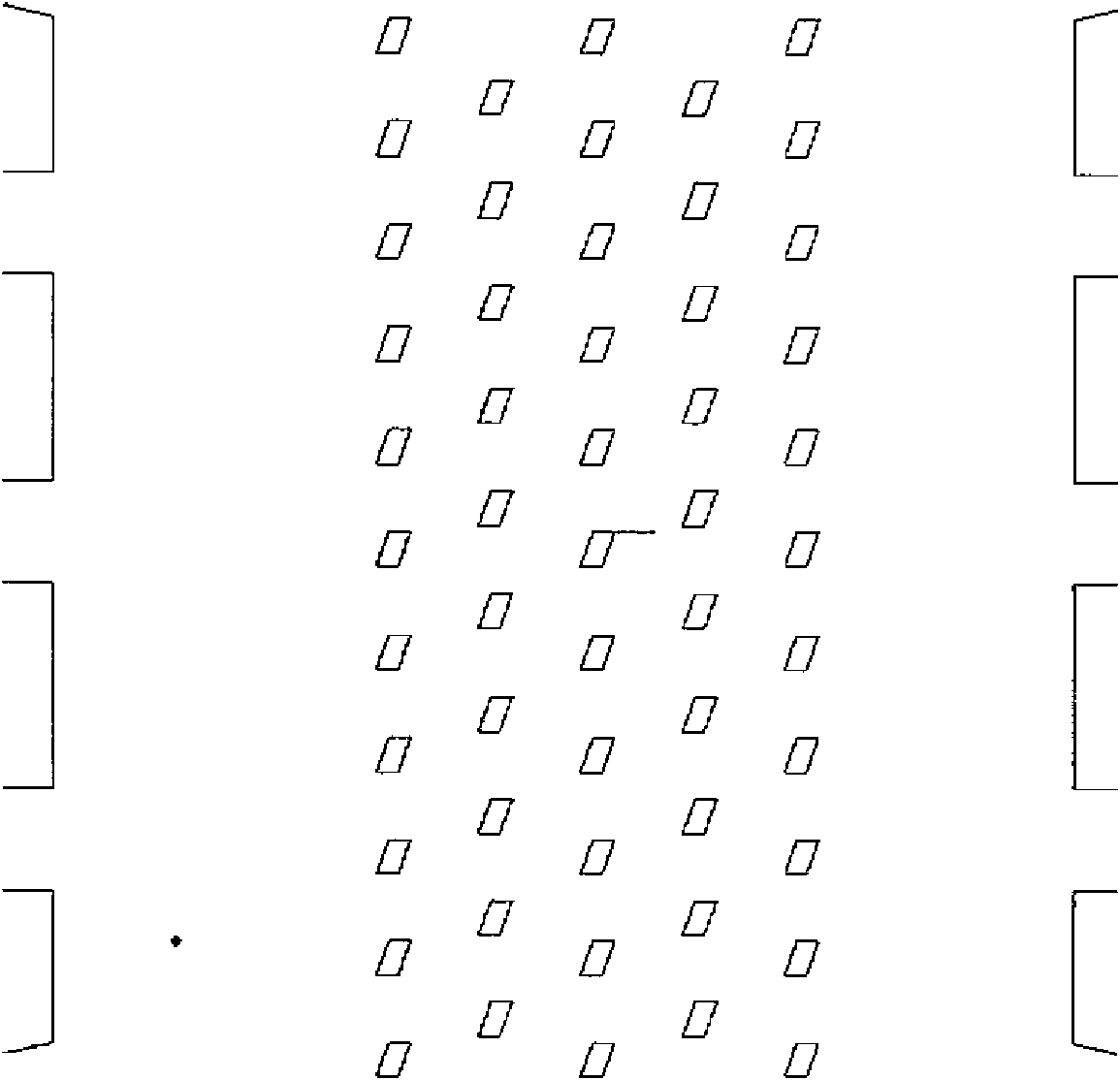

[0045] Using the vertical ring magnetic separator for fly ash iron removal according to the present invention, the magnetic field distribution diagram after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com