Method for large-scale purification of fusion proteins containing histaq and formate hydrolysis sites

A fusion protein, large-scale technology, applied in the field of protein purification, can solve the problems of low yield and increased by-products, and achieve the effects of high yield, short time consumption and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

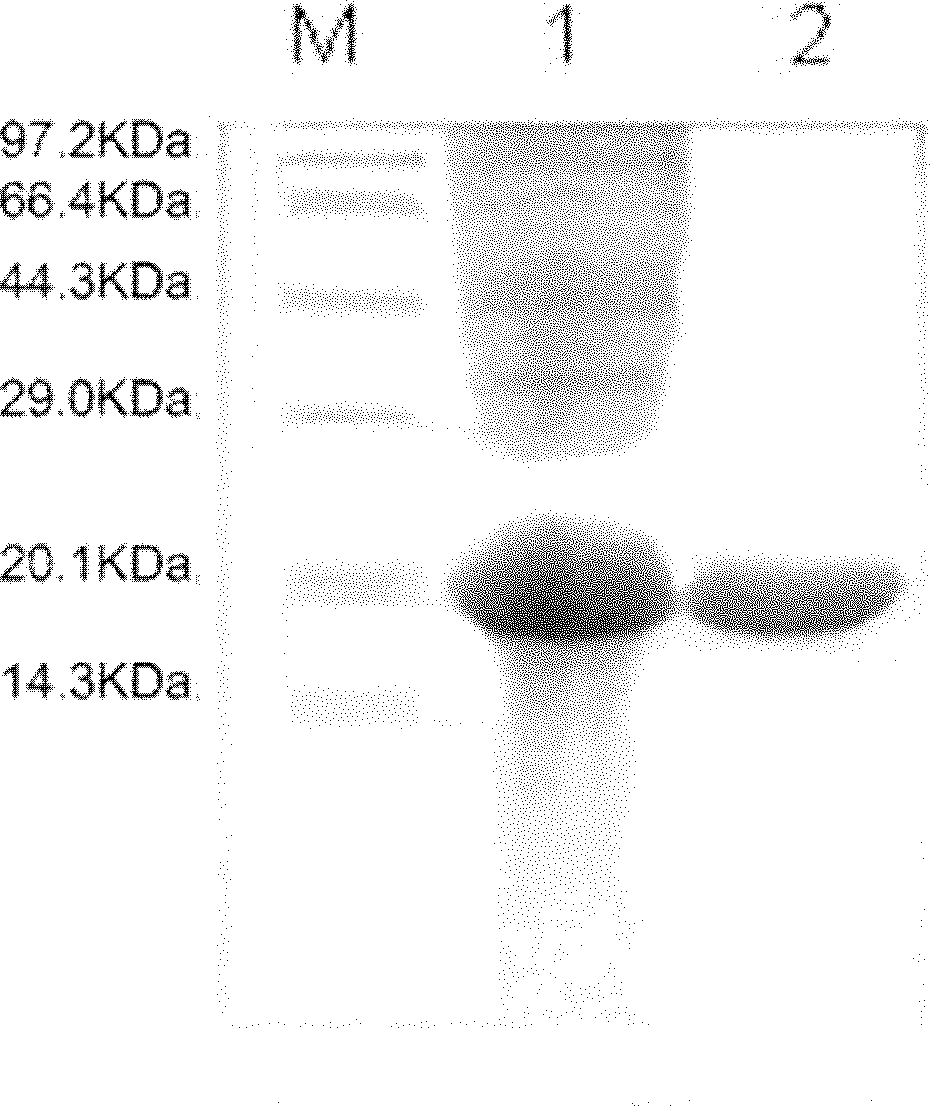

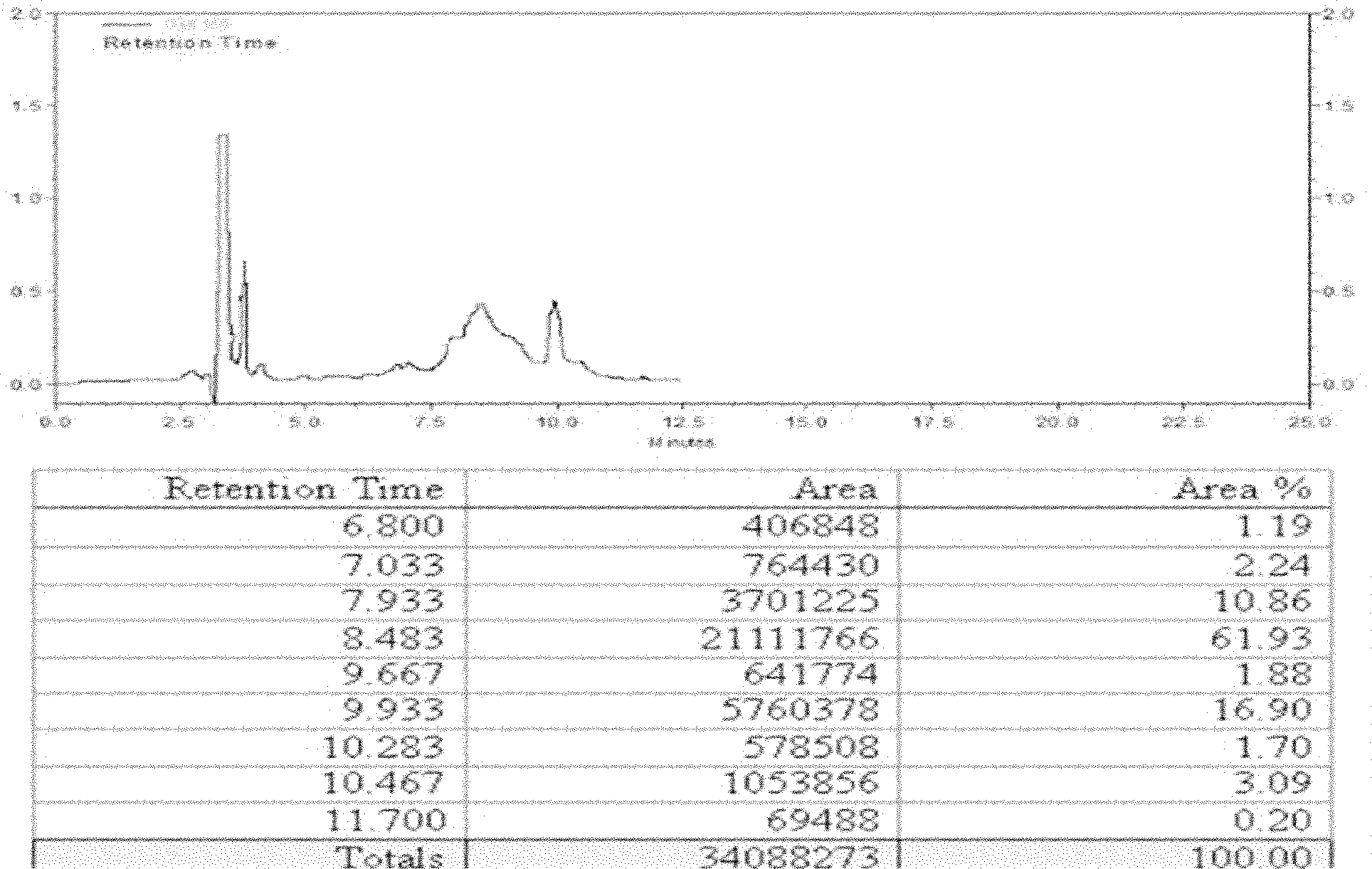

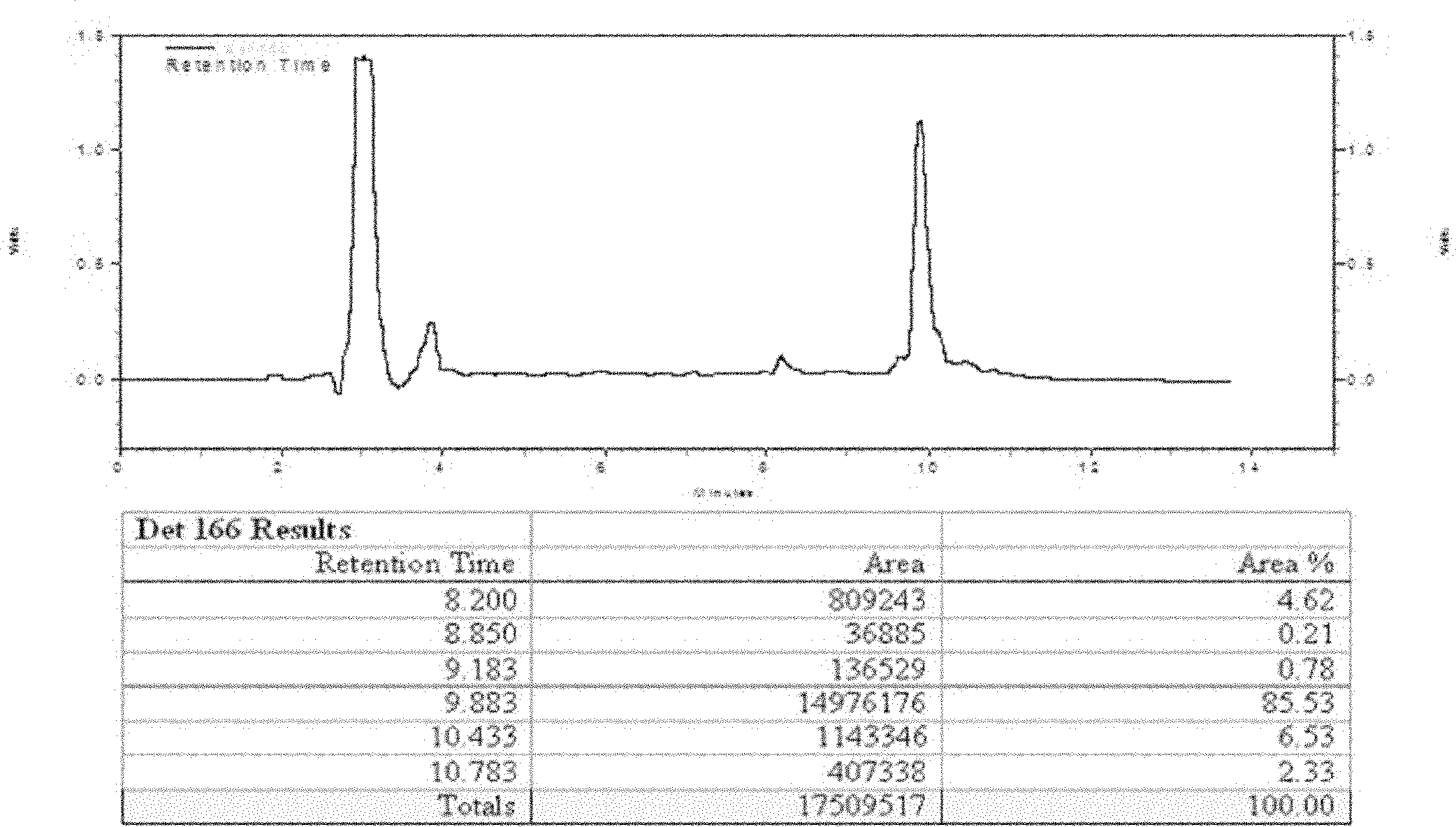

Embodiment 1

[0058] (1) Pretreat the fermentation broth of the engineered bacteria expressing the fusion protein containing His Taq and formic acid hydrolysis sites to obtain a crude extract of the fusion protein containing His Taq and formic acid hydrolysis sites:

[0059] 2100ml of PBS buffer with pH 7.4 and 50mM was added to 210g of wet bacterial cells (obtained from fermentation in Example 1 of Patent Application No. 201010221511.8) and mixed uniformly to obtain a bacterial cell suspension. The bacterial suspension is broken once in a high-pressure homogenizer (pressure 150MPa). The supernatant was discarded by centrifugation at 4°C at 10,000 rpm for 30 minutes, and the pellet was taken. The sample was present in the pellet as inclusion bodies. Wash the precipitate with 2100ml washing solution A (pH 8.0, 20mM Tris-HCl), and the washing method is 50rpm / min stirring for 10min; then centrifuge at 4°C 10000rpm for 30min to discard the supernatant and take the precipitate. Wash the pellet wit...

Embodiment 2

[0088] (1) Pretreating the fermentation broth of the engineered bacteria expressing the fusion protein containing His Taq and formic acid hydrolysis sites to obtain a crude extract of the fusion protein containing His Taq and formic acid hydrolysis sites: Same as step (1) in Example 1, The only difference is that the sample is 300g of bacteria obtained from fermentation in Example 2 of Patent Application No. 201010221511.8, and the volume of the solution used is 10 times the mass of the bacteria. The washed precipitate is washed with 20mM imidazole-containing dissolution buffer A (6M Urea, 50mM Na 2 HPO 4 , 500mM NaCl, pH 8.0) dissolved.

[0089] (2) Initial purification of crude fusion protein extract

[0090] A. Equilibrate the Ni-NTA column with 20mM imidazole-containing lysis buffer A (same step (1)) to stabilize the baseline, and then load the crude fusion protein extract obtained in step (1) onto the column at a flow rate of 4ml / min, Ni -The loading capacity of the NTA colum...

Embodiment 3

[0107] (1) Pretreating the fermentation broth of the engineered bacteria expressing the fusion protein containing His Taq and formic acid hydrolysis sites to obtain a crude extract of the fusion protein containing His Taq and formic acid hydrolysis sites: Same as step (1) in Example 1, The only difference is that the sample is 370 g of the bacteria obtained by fermentation in Example 3 of Patent Application No. 201010221511.8, the pressure of the high-pressure homogenizer is 120 MPa, and the volume of the solution used is 10 times the mass of the bacteria.

[0108] (2) Initial purification of crude fusion protein extract

[0109] A. Equilibrate the Ni-NTA column with 10mM imidazole-containing lysis buffer A (same step (1)) until the baseline is stable, and then load the crude fusion protein extract obtained in step (1) on the column at a flow rate of 6ml / min. -The loading capacity of the NTA column is 24.9mg protein / ml column volume; after loading the column, wash the column to bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com