Method for optimizing cold box and demethanizer system in sequential separation flow of cracked gas

A demethanizer and sequential separation technology is applied in the field of chemical engineering to achieve the effect of reducing ethylene loss and reducing ethylene loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The invention applies the refrigerant consumption of different temperature grades of the cold box and the demethanizer system in the ethylene plant to optimize configuration. Example:

[0047] 2)-5) the embodiment of concrete application:

[0048] First, the actual operating data of the device was collected, and errors were proposed for each historical data in the operation of the device according to the principle of error judgment, and the main operating parameters of the device were obtained as shown in Table 1 below.

[0049] Table 1. Main parameters of device operation before optimization

[0050]

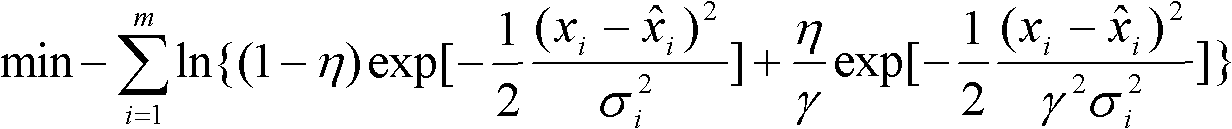

[0051] Based on the main operating process parameters and the unapplied platform of the chemical process simulation software, the process mechanism model of the cold box and demethanizer system is established, and the intelligent optimization algorithm adopted in the present invention is integrated and developed in the mechanism model. Through optimization After solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com