Living body measurement method and device of thickness of rice leaf

A technology of thickness measurement and thickness measurement, which is applied in the method and its measuring device, and the field of rice leaf thickness measurement in vivo, which can solve the problems of destroying samples, tedious work, and changes in leaf thickness, so as to save the sampling process and cumbersome process , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

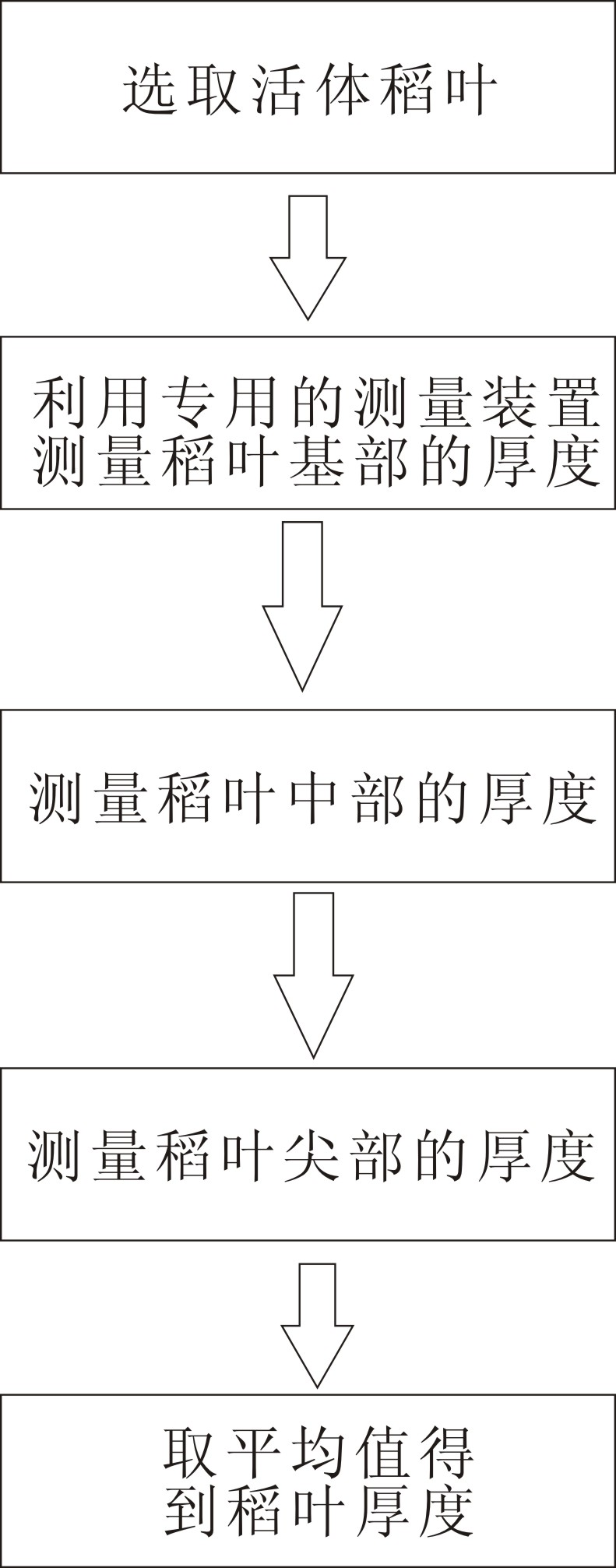

[0021] Such as figure 1 Shown, a kind of method for measuring rice leaf thickness in vivo comprises the following steps:

[0022] A. Select the growing rice leaf as the measurement object;

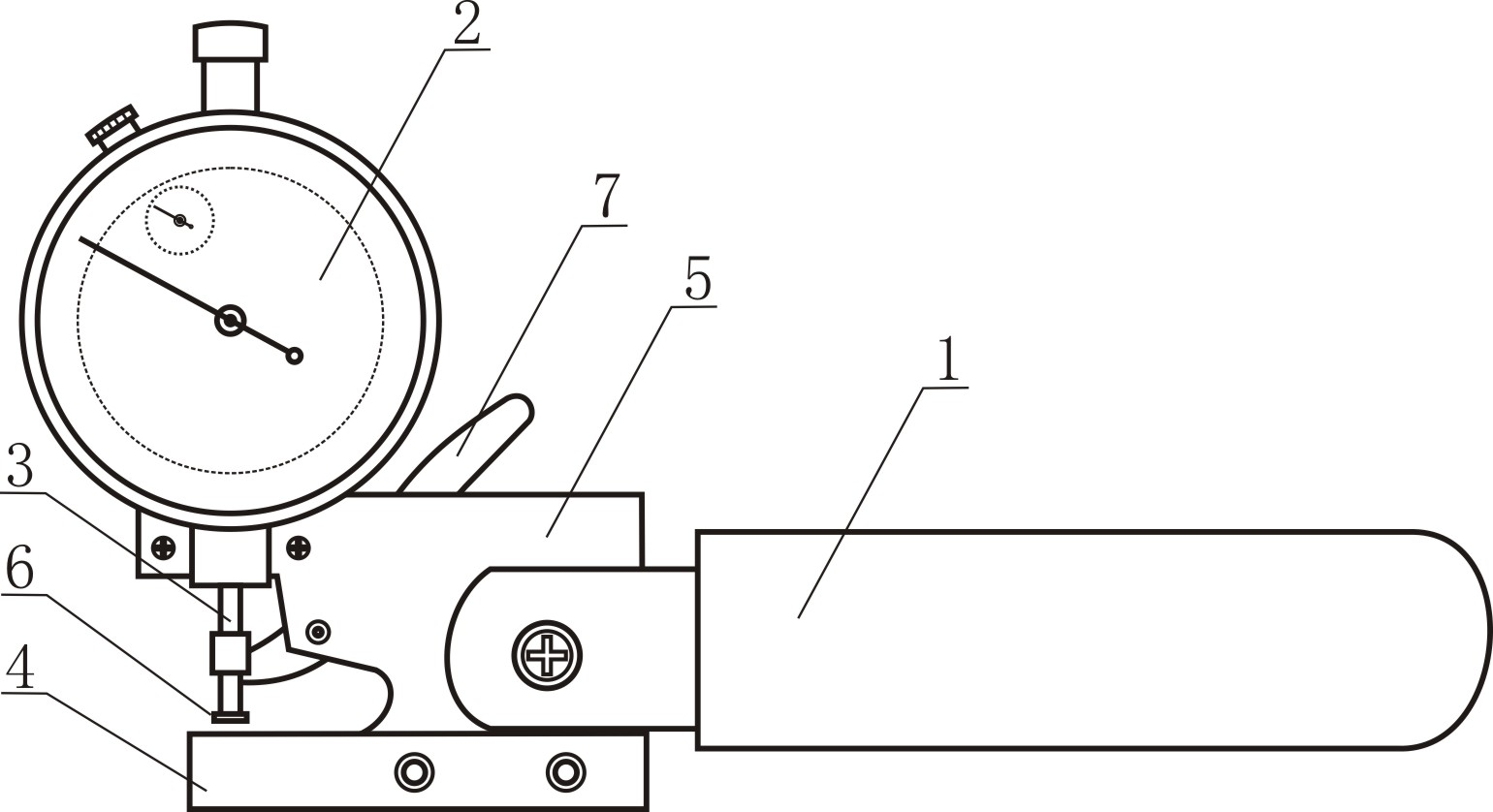

[0023] B. Utilize a special leaf thickness measuring device to measure the base of the rice leaf, place the rice leaf between the rice leaf contact plate 6 and the base 4 of the leaf thickness measuring device, and the base measurement point of the rice leaf is the starting point with the leaf tip The thickness of the base of the rice leaf is measured by measuring 2 / 3 of the length of the whole leaf and avoiding the main vein of the rice leaf;

[0024] C. Use the leaf thickness measuring device to measure the middle part of the rice leaf, place the rice leaf between the rice leaf contact plate 6 and the base 4 of the leaf thickness measuring device, and avoid the main vein of the rice leaf, thereby measuring the rice leaf the thickness of the middle;

[0025] D. Utilize the leaf thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com