System and method for detecting defects of fabric gray cloth quickly

A grey fabric and fast technology, applied in the field of inspection systems, can solve the problems of inability to meet real-time and high-speed online inspection requirements, high-speed online image acquisition and processing takes time, lack of high-speed image processing algorithms, etc. Fast, real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

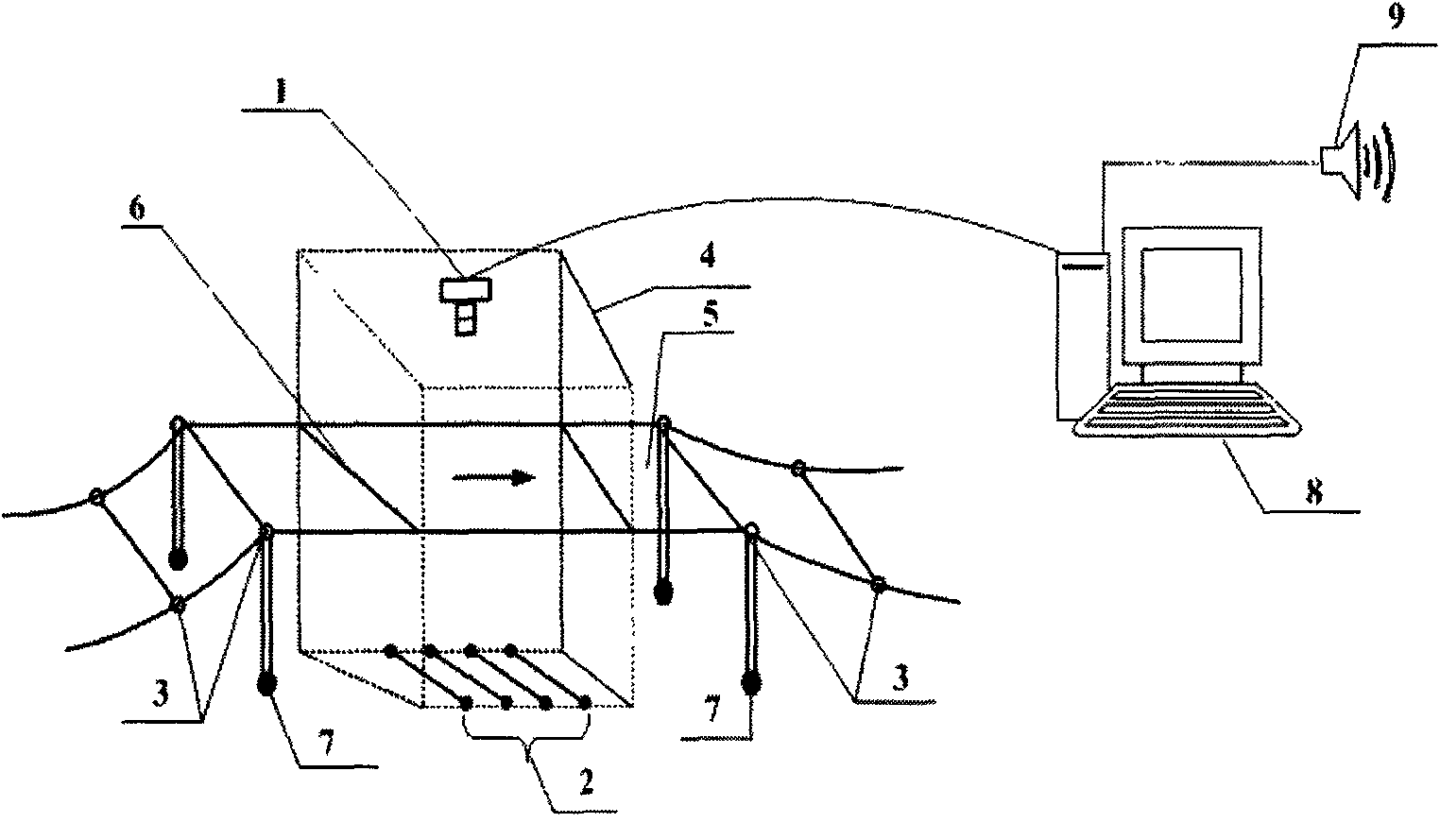

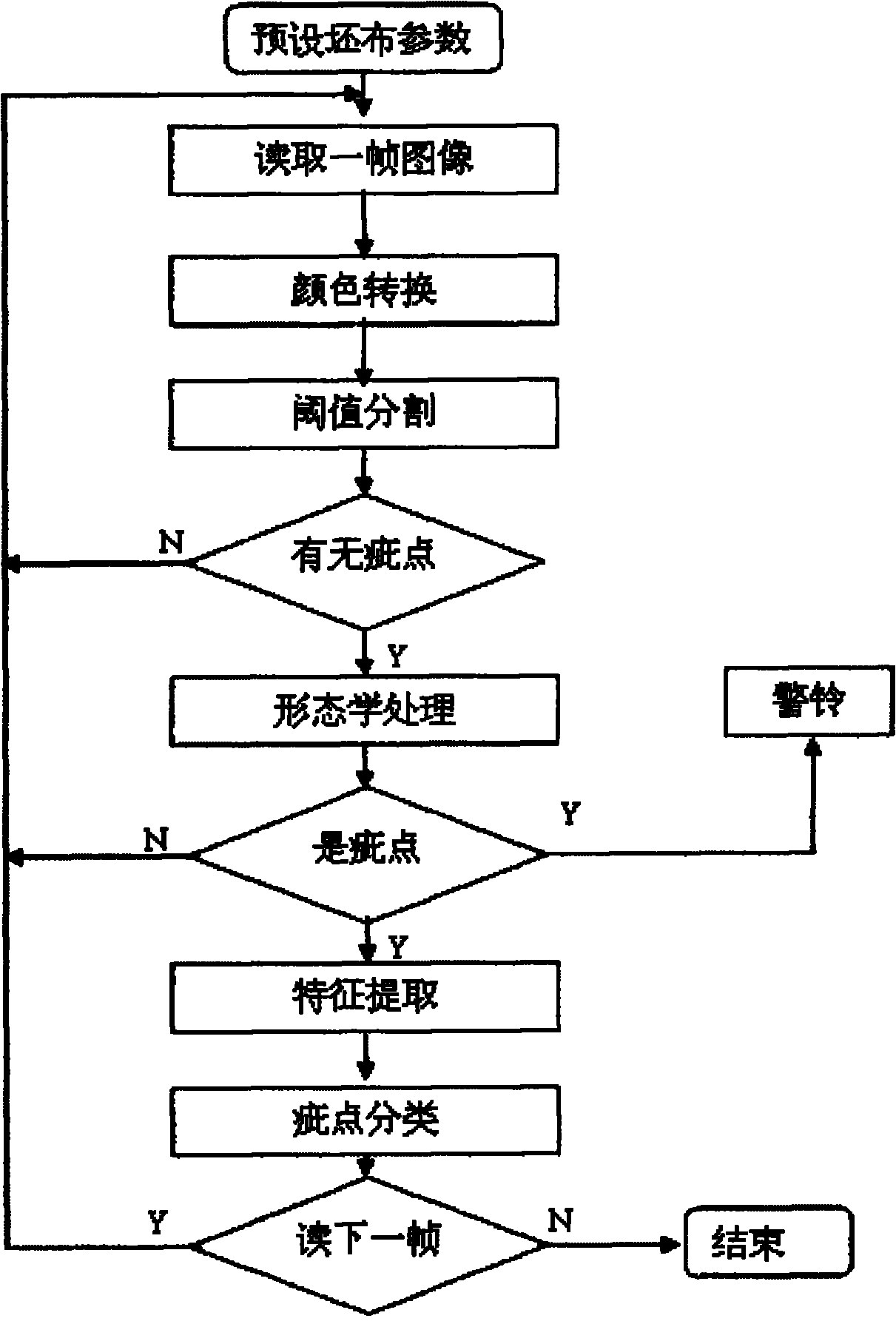

[0034] Such as figure 1 As shown, the structure schematic diagram of the online rapid automatic detection system for fabric defects of the present invention includes a CCD camera (1), a computer (8) equipped with an image acquisition card and an assembly line operation platform (7), and the assembly line operation The platform is equipped with a cloth guide rail (3) for guiding the gray cloth, two gray cloth slots (6) and a shielding device (4), and the CCD camera (1) is fixed on the shielding device (4) directly above the gray cloth (5). ), visually aim at the surface of the gray cloth (5), the lens of the CCD camera (1) is embedded in the shielding device (4), and its field of view is exactly the projection range of the shielding device on the horizontal plane. A group of LED light sources (2) are fixed below the fabric gray cloth (5), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com