Method for controlling outlet temperature of electric heater in supercritical water treatment system

An electric heater and outlet temperature technology, which is applied in the direction of using electric means for temperature control, auxiliary controller with auxiliary heating device, etc., to achieve the effect of improving dynamic quality and enhancing anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

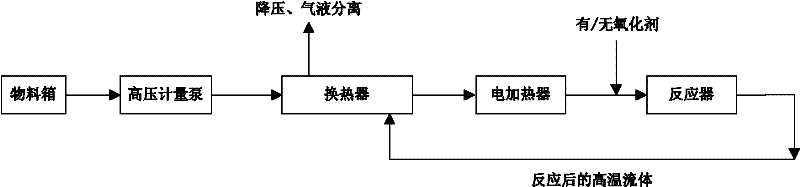

[0027] refer to figure 1 , the simplified process of the supercritical water treatment system is as follows: the material is firstly pressurized by the high-pressure metering pump and the flow rate is adjusted, then the high-temperature fluid is fully preheated by the heat exchanger, and then enters the electric heater to be further heated (when the system starts or when the heat is insufficient), then directly enter (in the case of SCWG) or mix with oxygen (in the case of SCWO and SWPO) and then enter the reactor for reaction. The high-temperature fluid after the reaction enters the heat exchanger and is fully cooled by the material fluid. Then enter the subsequent steps of decompression and gas-liquid separation to complete the entire process. Therefore, electric heaters play a very important role in supercritical water treatment systems. In the actual operation process, in order to effectively use the heat of the system and reduce the operating cost of the system, the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com