Microemulsion transdermal gel agent of butylphthalide or derivative thereof, and preparation method thereof

A derivative, butylphthalide technology, applied in the field of medicine, can solve the problems of difficult industrialized production, improved water solubility, and many key control points, so as to improve the safety and comfort of medication, reduce irritation, and reduce oiliness. effect of feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

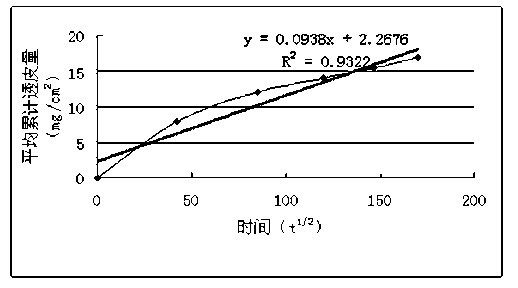

Embodiment 1

[0045] Butylphthalide 0.2g;

[0046] Medium-chain triglycerides 1.6g;

[0047] Polyoxyethylene hydrogenated castor oil 2g;

[0048] Glycerin 1g;

[0049] Azone 0.1g;

[0050] Purified water 5g;

[0051] Weigh butylphthalide, add it to medium-carbon chain triglyceride, stir evenly, then add polyoxyethylene hydrogenated castor oil and glycerin, mix evenly, add azone, then add purified water, stir to make it a microemulsion gel, Its particle size was measured to be about 68nm.

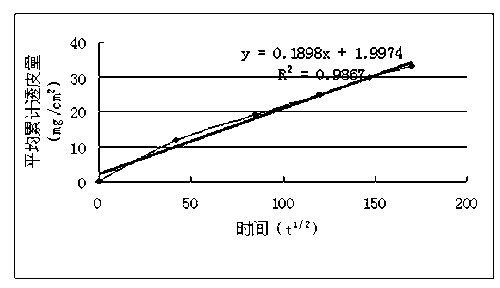

Embodiment 2

[0053] Butylphthalide 0.4g;

[0054] Medium-chain triglycerides 2g;

[0055] Polyoxyethylene hydrogenated castor oil 2g;

[0056] Glycerin 1g;

[0057] Azone 0.1g;

[0058] Purified water 4.6g;

[0059] Weigh butylphthalide, add it to medium-carbon chain triglyceride, stir evenly, then add polyoxyethylene hydrogenated castor oil and glycerin, mix evenly, add azone, then add purified water, stir to make it a microemulsion gel, Its particle size was measured to be about 41 nm.

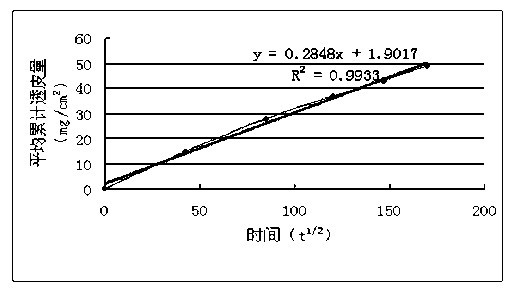

Embodiment 3

[0061] Butylphthalide 0.6g;

[0062] Medium-chain triglycerides 2g;

[0063] Polyoxyethylene hydrogenated castor oil 2g;

[0064] Propylene glycol 1g;

[0065] Azone 0.1g;

[0066] Purified water 4.3g;

[0067] Weigh butylphthalide, add it to medium-carbon chain triglyceride, mix evenly, then add polyoxyethylene hydrogenated castor oil, propylene glycol, mix evenly, add azone, then add purified water, stir to make it a microemulsion gel, Its particle size was measured to be about 41 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com