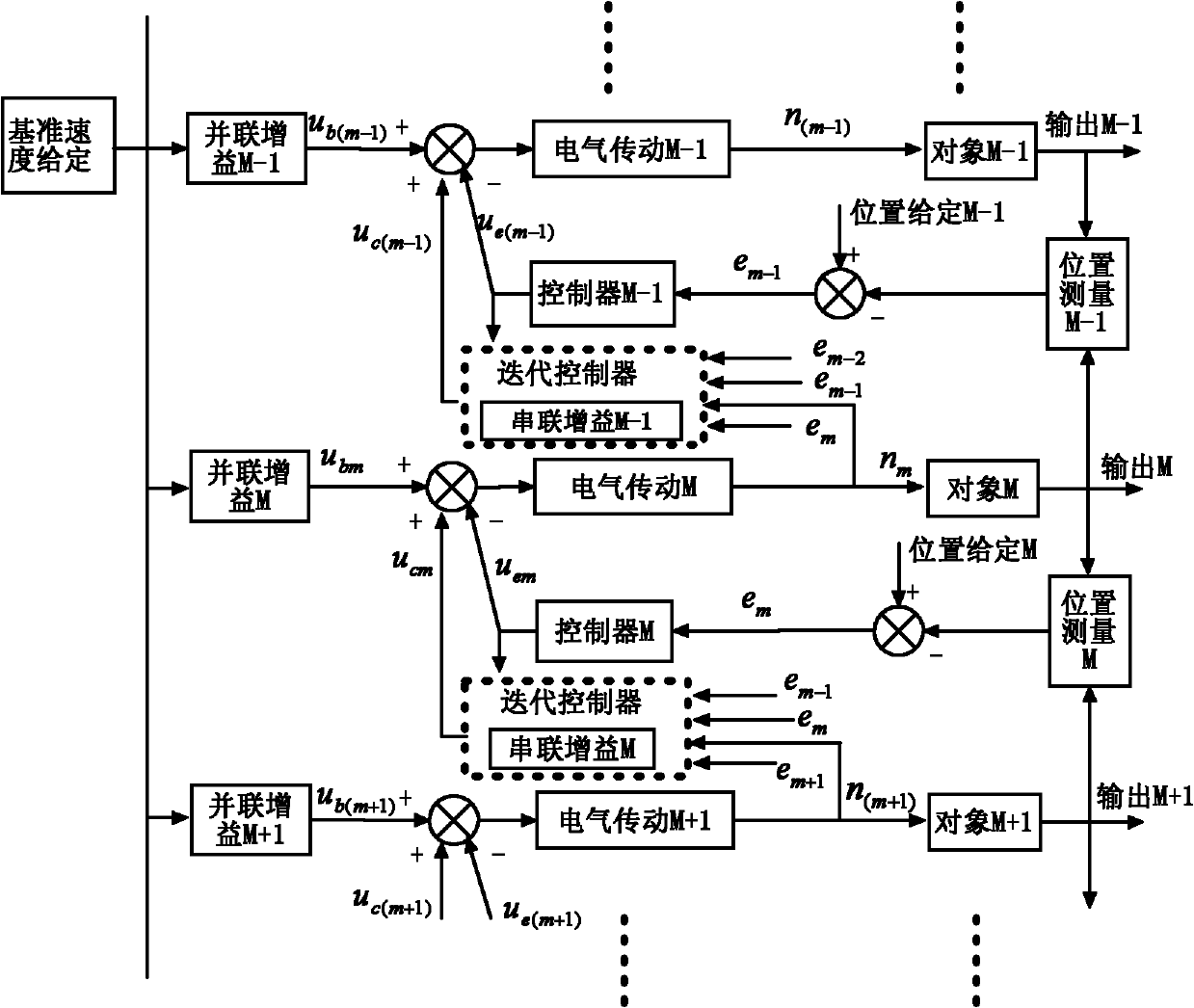

Superspeed wire rod extension processing equipment control system

A processing equipment and control system technology, applied in the field of wire rod extension processing equipment control system, can solve problems such as low control accuracy and poor tracking control accuracy, and achieve the effects of improving error compensation, improving rapidity, and reducing estimation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

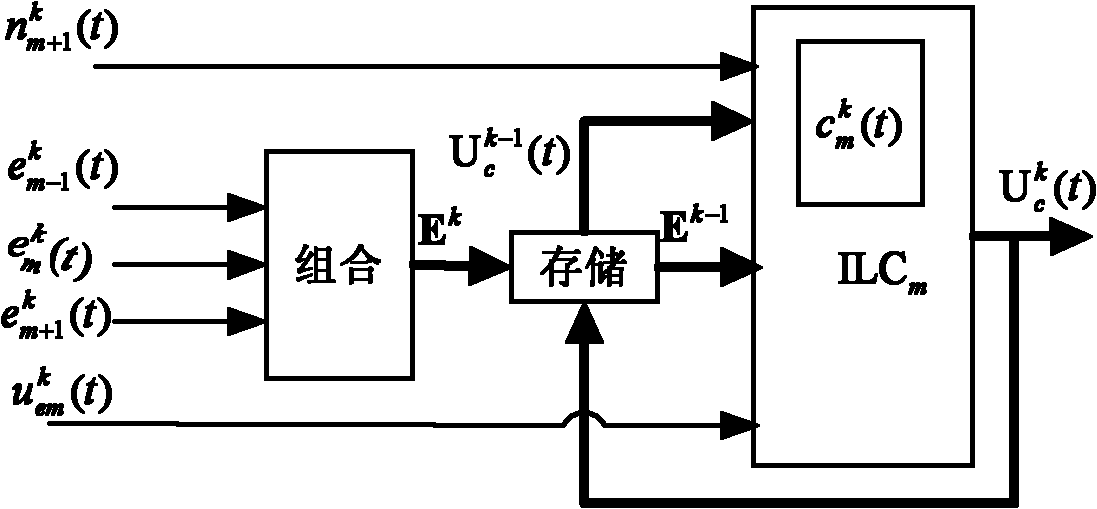

Method used

Image

Examples

example

[0042] Example: Take the 12-pass ultra-high-speed wire extension processing equipment as an example, select a 37KW motor, design the mechanical transmission ratio, match the die diameter, and calculate the compression ratio. When the finished product pass is 80m / s, the given speed voltage is 5v, the sampling period is 10ms, and the iteration period is 0.5s. Get position error e m , position error U em , series input U cm , taking the 8th pass as an example, the value is taken every 0.5s, the list is as follows:

[0043] time t(s)

[0044] time t(s)

[0045] time t(s)

[0046] It can be seen from the experiment that the position error e m , the speed control value U of the position error output em , are reduced to 0 within 10s, the speed control value U input in series cm Linear relationship with a given speed, U cm =1 / 2U n , thus verifying the accuracy, rapidity and feasibility of the iterative learning control system based on 2D system on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com