Casting machining special cutter with replaceable cutter bit

A technology of cutter heads and cutters, which is applied in the field of special cutters and cutters for casting mold processing. It can solve the problems of poor wear resistance, short length, and interference in processing deep cavities, so as to avoid interference, improve poor wear resistance, and solve the problem of tool wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the specific embodiment of patent of the present invention is described in detail:

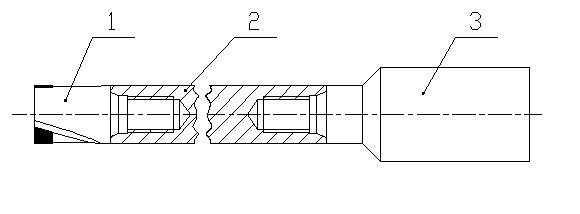

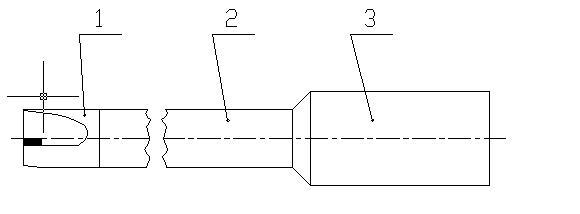

[0027] figure 1 It is the front view of the special cutting tool for casting mold processing with replaceable cutting head of the present invention, figure 2 A top view of a special tool for mold processing with replaceable heads, image 3 Side view of a special tool for casting with replaceable heads. The special tool for casting mold processing with replaceable cutter head includes a cutter head 1, a connecting rod 2, and a knife handle 3.

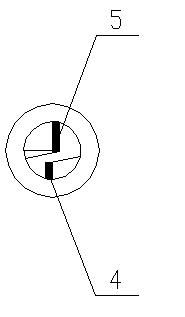

[0028] Figure 4 It is the head diagram of the special tool. 2 cutting inserts are mounted on the head (see image 3 The short blade 4 of the special tool and the long blade 5 of the special tool) are made of PCD, (polycrystalline diamond, the abbreviation of Polycrystalline diamond, which is sintered with fine-grained diamond single crystal under high temperature and high pressure, and has goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com