Device for intelligently detecting abrasion of numerical control cutting tool

A technology for intelligent detection and tool wear, which is applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc. It can solve problems such as not being able to be controlled in time, affecting the quality and automation level of product processing, and achieving convenient control and high versatility. and practical value, the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention will be described in detail below in conjunction with the drawings.

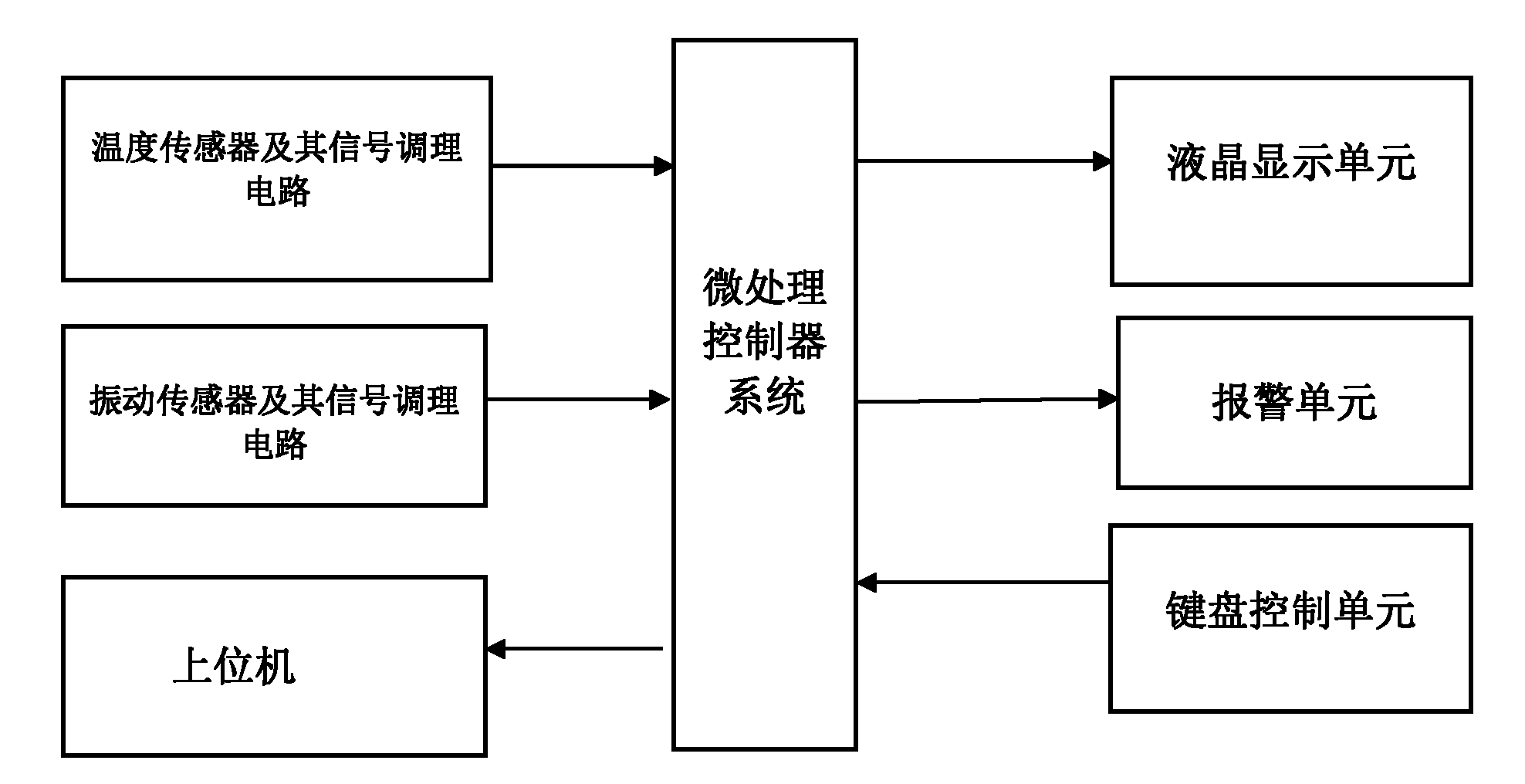

[0033] Main hardware part

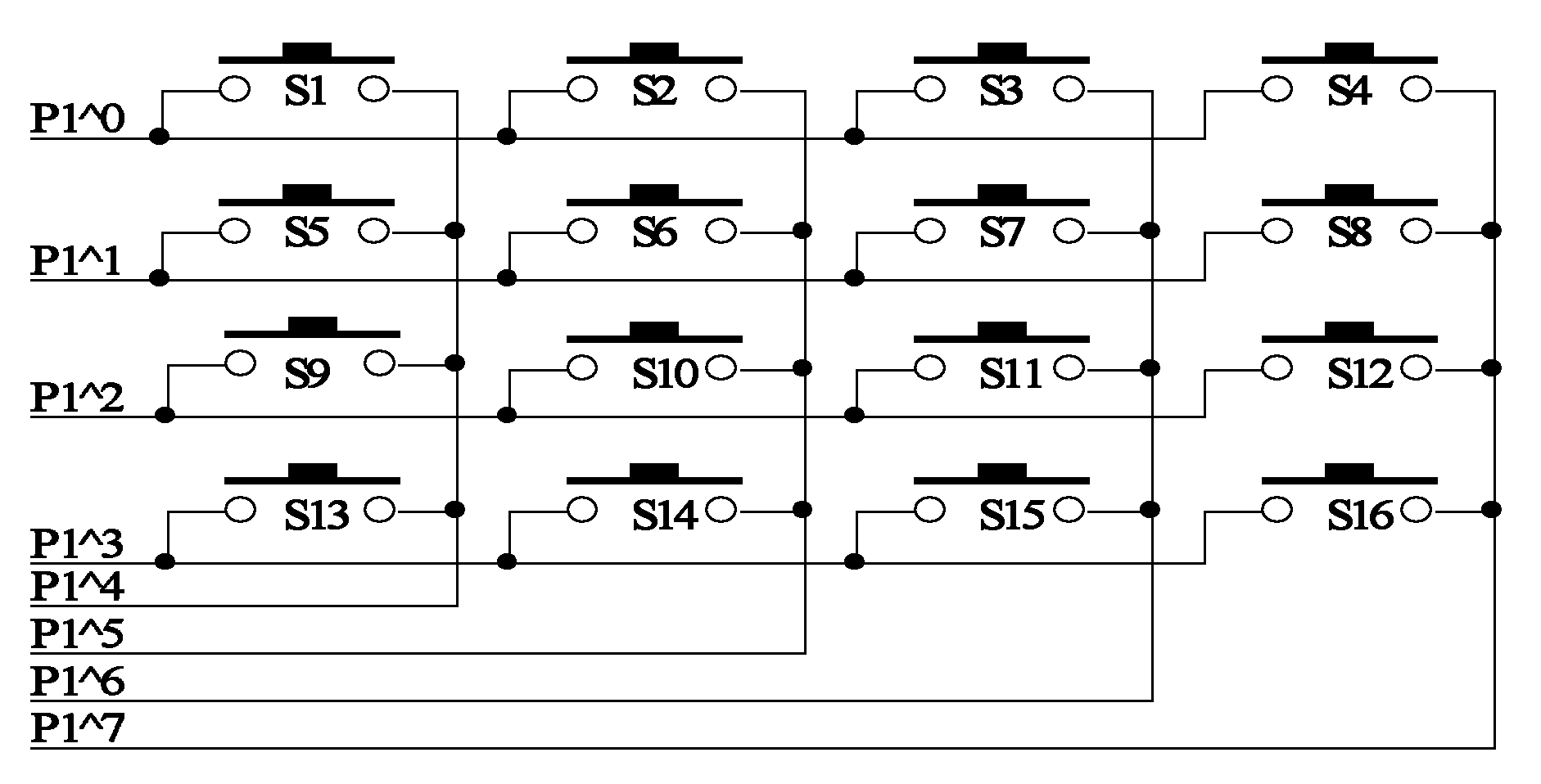

[0034] CNC tool wear intelligent detection system hardware, the whole circuit is composed of sensor signal processing circuit, matrix film button circuit, single-chip control circuit, alarm circuit, liquid crystal display circuit, and RS232 interface circuit.

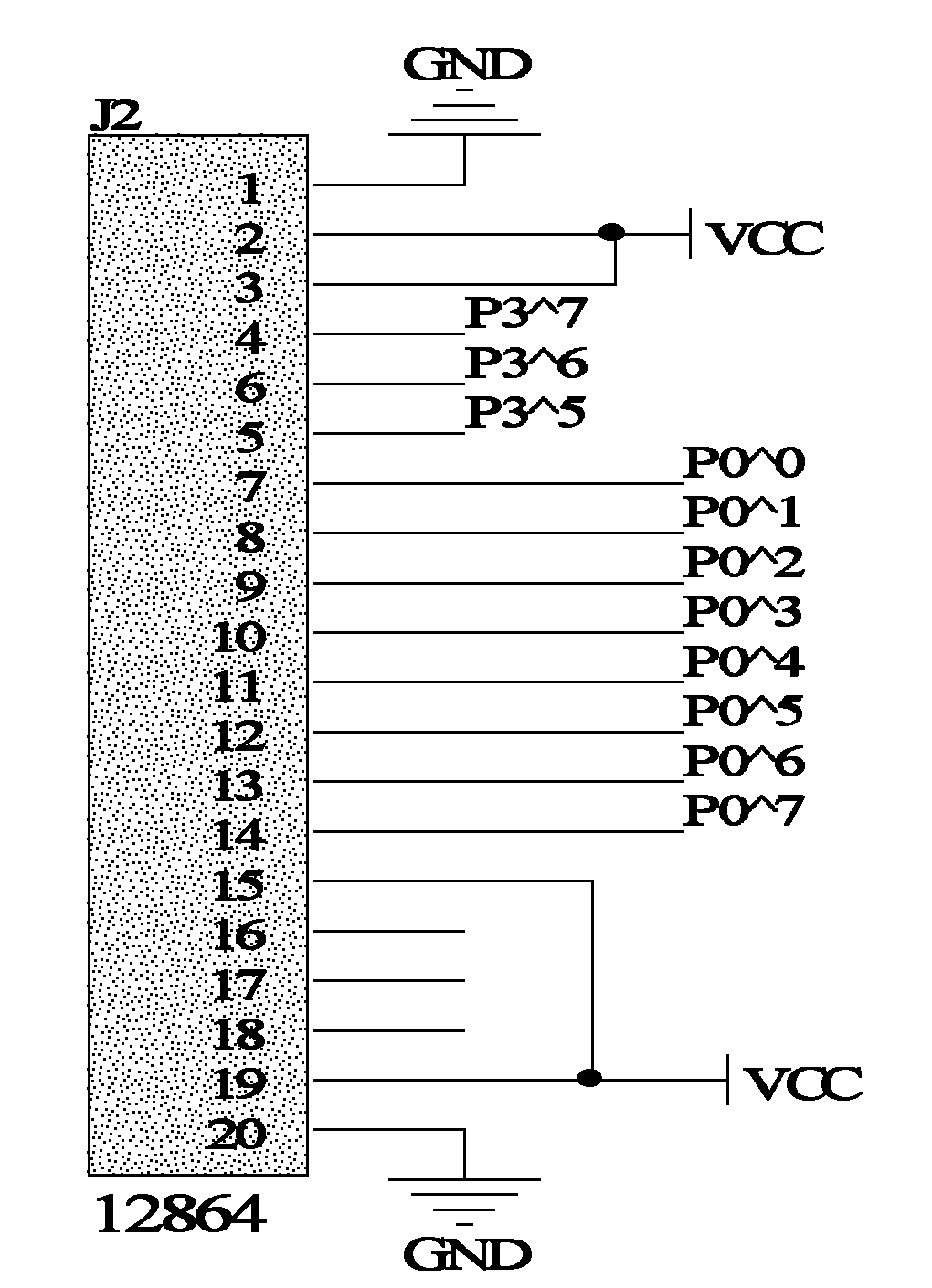

[0035] 1. Liquid crystal display circuit (such as figure 2 )

[0036] The 12864 Chinese graphic display liquid crystal with ST7920 as the controller and server used in the circuit. It mainly realizes the reality of the tool material selection interface before the tool processing, the interface display of the corresponding operation prompts, and the dynamic display of the measured parameters during the tool processing. The liquid crystal display module has two connection methods: parallel and serial. In order to improve the response speed of the system, this device adopts the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com