Dielectric substance discharge food storage device

A storage device and dielectric technology, applied in the direction of transportation and packaging, anti-rot containers, containers, etc., to reduce power consumption, achieve long-term storage, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

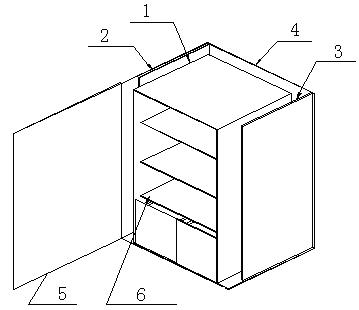

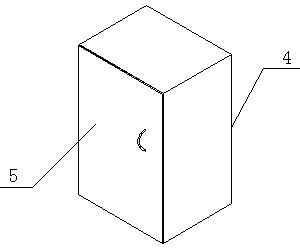

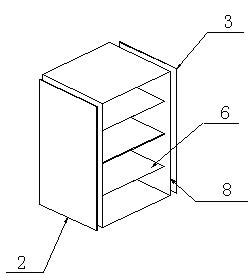

[0023] Examples of the present invention figure 1 shown. The dielectric discharge food storage device of the present invention is composed of a box shell 4, a food storage platform 6, a dielectric container and a catalyst structure 1, a power supply, a positive electrode plate 2 and a negative electrode plate 3; the dielectric container and the catalyst The structure is a five-sided cuboid container. The two side plates near the electrodes are made of stainless steel, and the inner wall of the structure is coated with a metal catalyst made of metal or metal oxide, and the rest of the separators are low dielectric materials; The electrical container and the catalyst structure are located inside the box body, and the side of the container facing the door 5 of the box body is empty, so that food can be placed in the container. A positive electrode plate and a negative electrode plate with discharge needles are respectively arranged on both sides of the mass container and the cat...

Embodiment 2

[0027] Examples of the present invention figure 1 shown. The dielectric discharge food storage device of the present invention is composed of a box shell 4, a food storage platform 6, a dielectric container and a catalyst structure 1, a power supply, a positive electrode plate 2 and a negative electrode plate 3; the dielectric container and the catalyst The structure is a four-sided cuboid container that runs through the front and back. The two side plates near the electrodes are made of aluminum alloy, and the inner wall of the structure is coated with a metal catalyst made of metal or metal oxide. The rest of the separators are made of low dielectric materials. The dielectric container and the catalyst structure are located inside the box body, and the front and back of the container pass through towards the box body door 5, so that food can be placed in the container, and the inner cavity of the dielectric container and the catalyst structure is placed on the food storage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com