A low -boiling spare precious metal intermediate package alloy alloy equipment and methods

A technology of rare and precious metals and tundishes, which is applied in metal processing equipment, casting equipment, casting molten material containers, etc., can solve the problems of low alloying yield, high consumption, and inability to alloy, and achieve stable yield, The effect of small investment, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through embodiment.

[0020] A tundish microalloying technology for low-boiling rare and precious metals in this embodiment, the test steel type is low-carbon high-sulfur free-cutting steel containing a small amount of bismuth, and its bismuth alloy composition content is 0.0002% to 0.0025%, and the microalloying metal The powder is pure bismuth (boiling point 1560°C), and the particle size of the powder does not exceed 200 mesh. Produced by the BOF-LF-CC process, the LF refining exit temperature is controlled at 1580-1620°C during production, the upper continuous casting platform temperature is about 1570-1580°C, and the first ladle pouring temperature is 1540-1560°C. The continuous casting adopts arc continuous casting machine, the casting speed of the three-strand billet is about 1.4-1.6m / min, and the cross-section of the billet is 150mm×150mm.

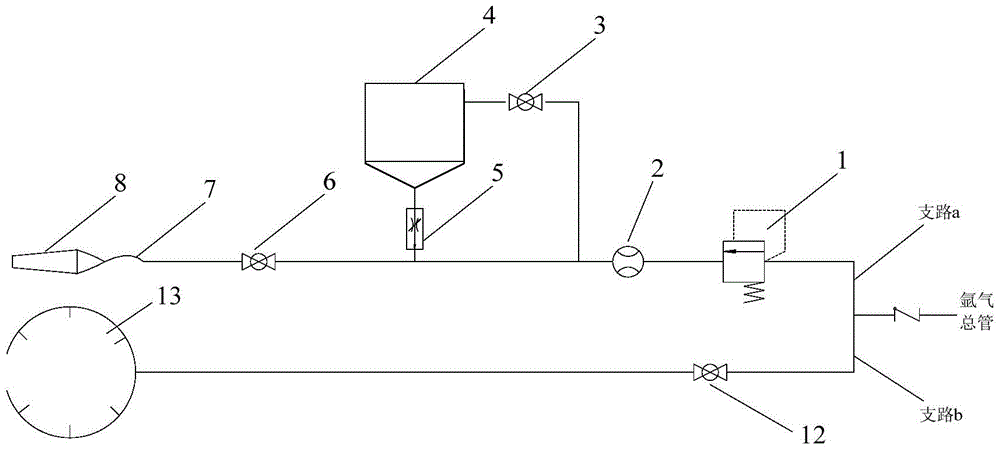

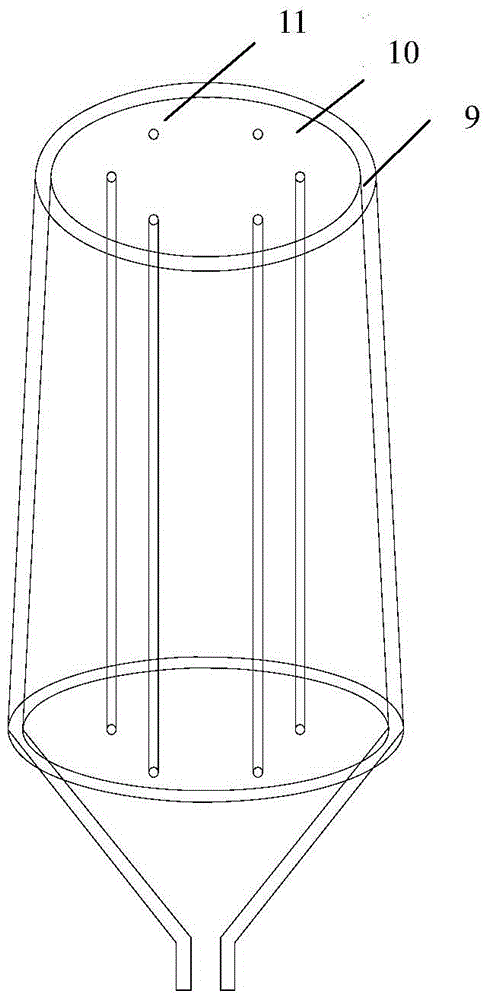

[0021] The pipe diameter of the branch a of the tundish microalloyi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com