Heat reflection heat insulation coating for outer wall

A heat-insulating coating and heat-reflecting technology, applied in reflective/signal coatings, coatings, etc., can solve the problems of short storage period of finished paint, porous surface of paint film, affecting construction, etc., and achieve excellent water resistance, complex production process, The effect of large construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

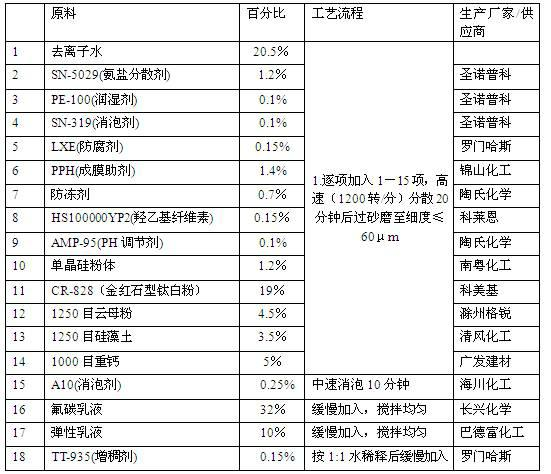

Embodiment 1

[0056] A heat-reflecting and heat-insulating coating for exterior walls. The coating components include, by weight percentage: 40% of film-forming materials; 34% of pigments and fillers; 1% of monocrystalline silicon powder; 3% of additives; and 22% of deionized water. The film-forming material includes water-based fluorocarbon emulsion and elastic emulsion; the pigment and filler include one or more of rutile titanium dioxide, mica powder, diatomaceous earth, and ultrafine heavy calcium; the auxiliary agent includes a dispersant , one or more of leveling agent, defoamer, preservative, thickener, film-forming aid, antifreeze. Water-based fluorocarbon emulsion and elastic emulsion are used as base materials, and monocrystalline silicon thermal insulation agent, multifunctional pigments and fillers (such as rutile titanium dioxide, diatomaceous earth, mica powder, superfine heavy calcium, etc.) and additives are introduced. It is applied on the surface of buildings and has the f...

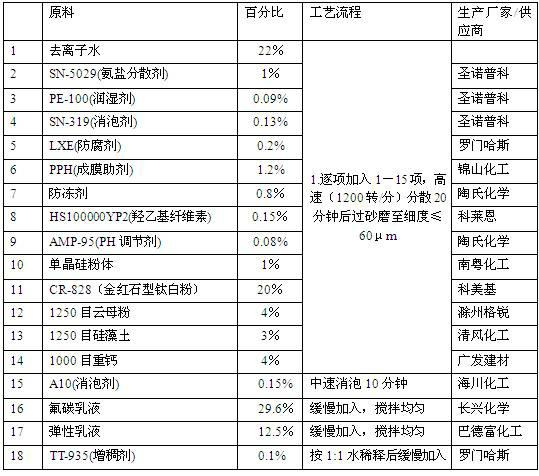

Embodiment 2

[0058] A heat-reflecting and heat-insulating coating for exterior walls. The coating components include, by weight percentage: 50% of film-forming materials; 29% of pigments and fillers; 1.5% of monocrystalline silicon powder; 5% of additives; and 15.5% of deionized water. The film-forming material includes water-based fluorocarbon emulsion and elastic emulsion; the pigment and filler include one or more of rutile titanium dioxide, mica powder, diatomaceous earth, and ultrafine heavy calcium; the auxiliary agent includes a dispersant , one or more of leveling agent, defoamer, preservative, thickener, film-forming aid, antifreeze. Water-based fluorocarbon emulsion and elastic emulsion are used as base materials, and monocrystalline silicon thermal insulation agent, multifunctional pigments and fillers (such as rutile titanium dioxide, diatomaceous earth, mica powder, superfine heavy calcium, etc.) and additives are introduced. It is applied on the surface of buildings and has t...

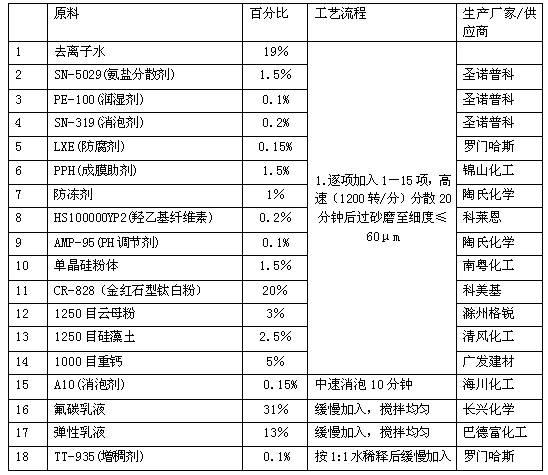

Embodiment 3

[0060] A heat-reflecting and heat-insulating paint for exterior walls. The paint components include, by weight percentage: 50% of film-forming material; 33.5% of pigment and filler; 1.5% of monocrystalline silicon powder; 5% of additive; and 10% of deionized water. The film-forming material includes water-based fluorocarbon emulsion and elastic emulsion; the pigment and filler include one or more of rutile titanium dioxide, mica powder, diatomaceous earth, and ultrafine heavy calcium; the auxiliary agent includes a dispersant , one or more of leveling agent, defoamer, preservative, thickener, film-forming aid, antifreeze. Water-based fluorocarbon emulsion and elastic emulsion are used as base materials, and monocrystalline silicon thermal insulation agent, multifunctional pigments and fillers (such as rutile titanium dioxide, diatomaceous earth, mica powder, superfine heavy calcium, etc.) and additives are introduced. It is applied on the surface of buildings and has the funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com