Method for distilling white wine

A distillation method and liquor technology, applied in the field of liquor distillation, can solve the problems of recycling yellow water and bottom pot water, etc., achieve the effects of increasing the content of aroma substances, improving the quality of liquor, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

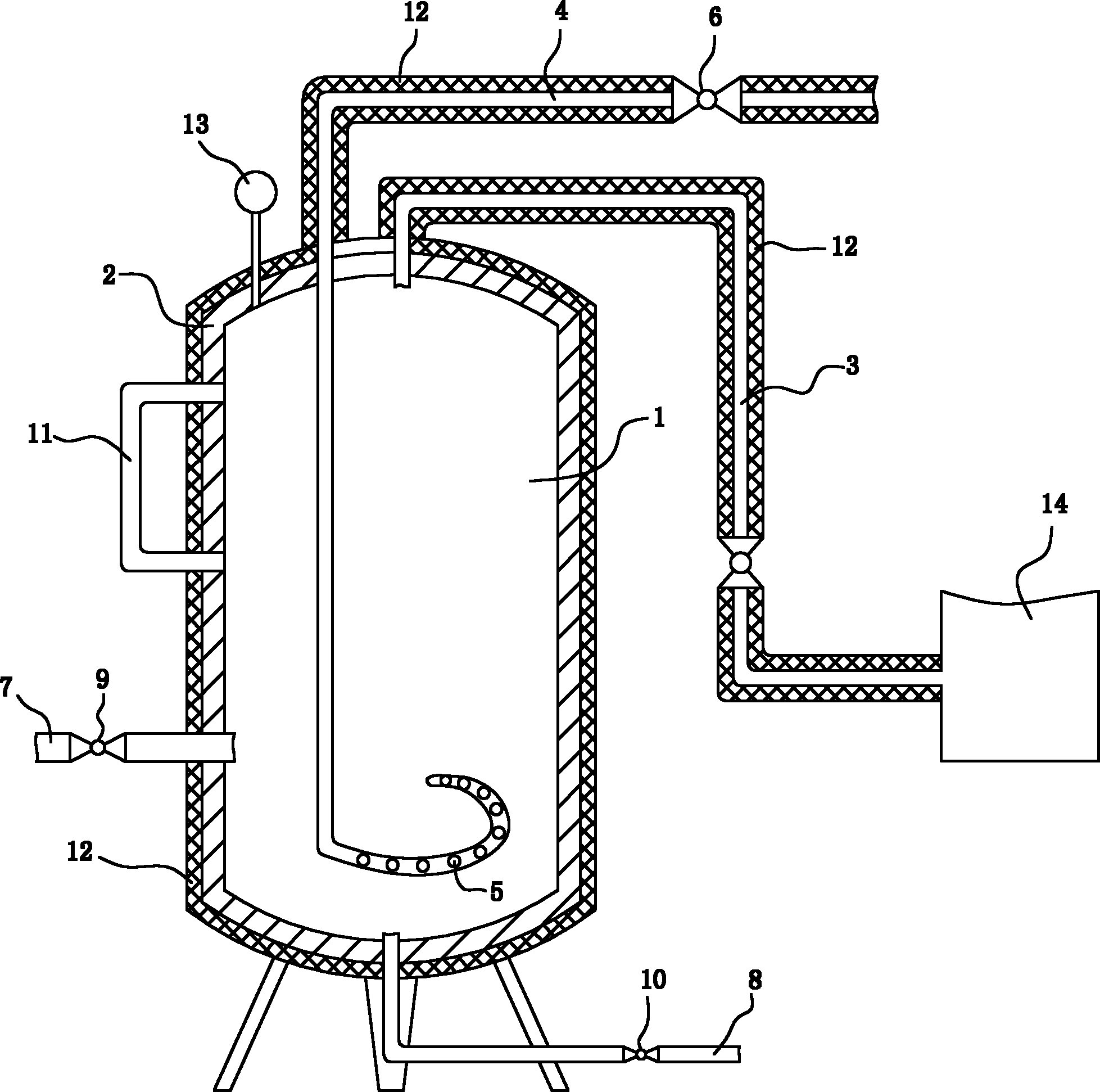

[0016] The liquor distillation method of the present invention is: adopt liquor brewing still to carry out distillation, described liquor brewing still comprises bottom pot 14, also includes the still body 2 that has still chamber 1, is provided with normal pressure steam pipe 3 on still body 2 , one end of the atmospheric pressure steam pipe 3 communicates with the still cavity 1, and the other end communicates with the cavity of the bottom pot 14; wherein, during distillation, the retort barrel is placed in the bottom pot 14, and 30 to 80 1 part of water, 5-40 parts of yellow water, 5-20 parts of basic wine, heat the still chamber 1 so that steam enters the retort barrel to distill the wine.

[0017] In the method of the present invention, the distiller's grains and other materials can be put into the retort according to the conventional distiller's distiller's process, and the consumption of water, yellow water, and basic wine can provide enough steam to distill the distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com