Industrial fabric with traction coating

A fabric, industrial technology in the field of corrugator "bottom belt" fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

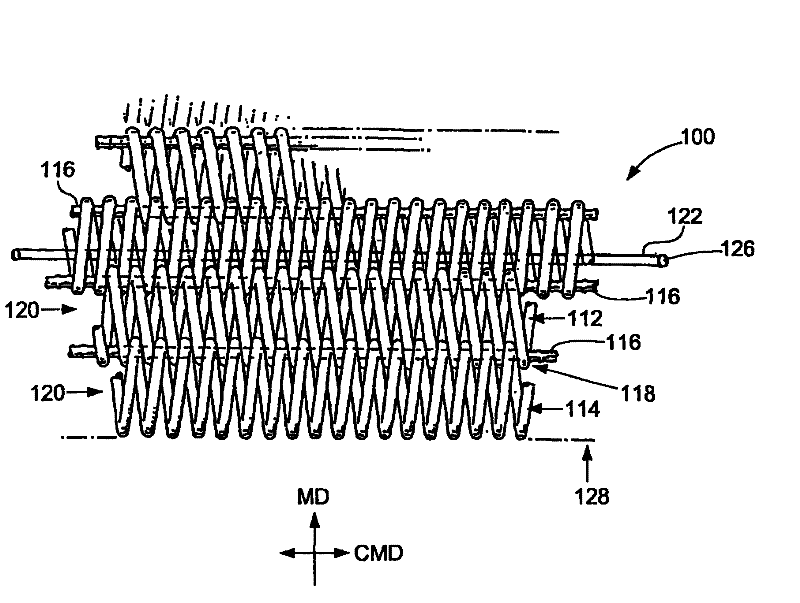

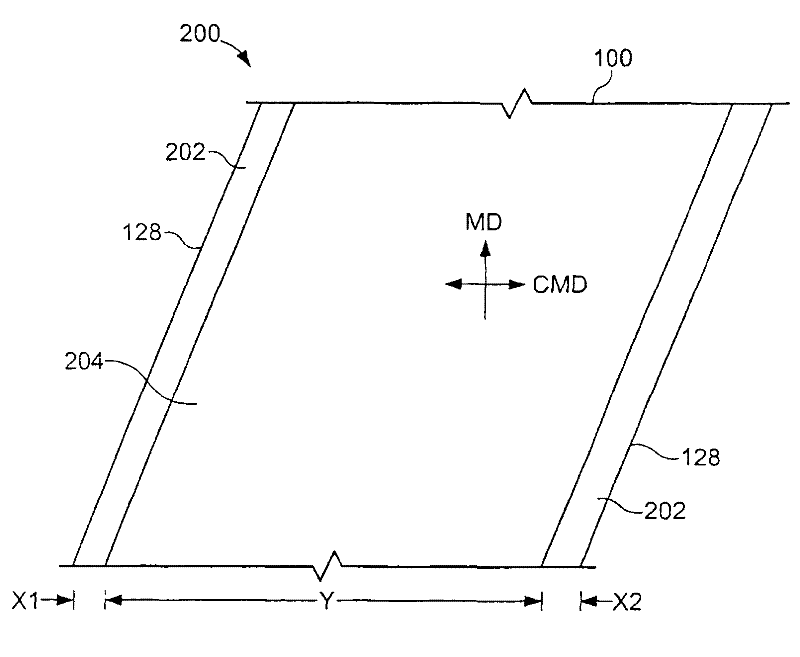

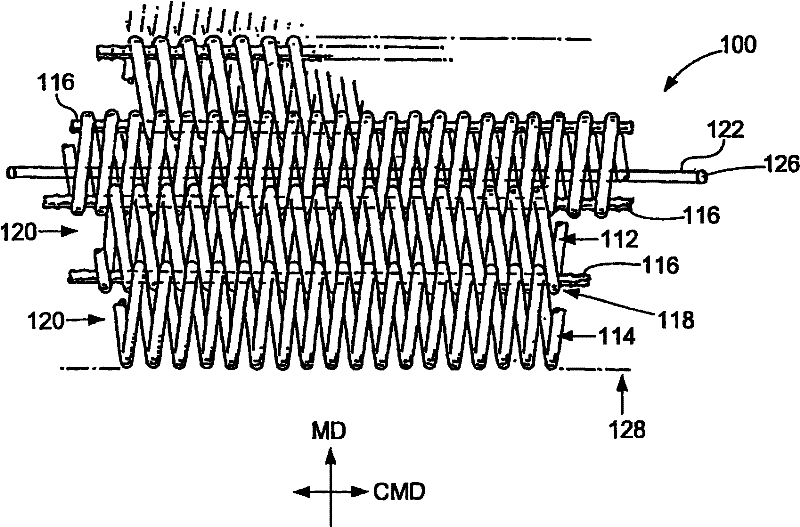

[0036] A nonwoven fabric for a corrugator was manufactured and constructed using polyester helices with a diameter of 0.90 mm and hinge pins with a diameter of 0.90 mm. Stretching and heat setting were performed at 48 pli and 210°C. After this was measured, a static control yarn (carburized nylon) having a diameter of 0.52 mm was inserted into the helix. The fabric was cut to the final dimensions of the customer's corrugator and then coated with a 1" conductive edge coating on each lateral edge in the form of a conductive carburized synthetic rubber. A silicon traction coating was applied to the The area adjacent to and between the conductive edge coatings covers the remainder of the base fabric and extends a distance of approximately 2 to 6 mm above the base fabric. The silicone rubber compound is then heat cured at 175°C, 48 pli.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com