Gable side sliding roof panel rigid waterproof system

A rigid waterproof and roof panel technology, applied in the field of sliding systems, can solve problems such as weak sliding connections and aging of nail hole sealants, and achieve the effects of solving nail hole water leakage, improving waterproof performance, and avoiding tearing of connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

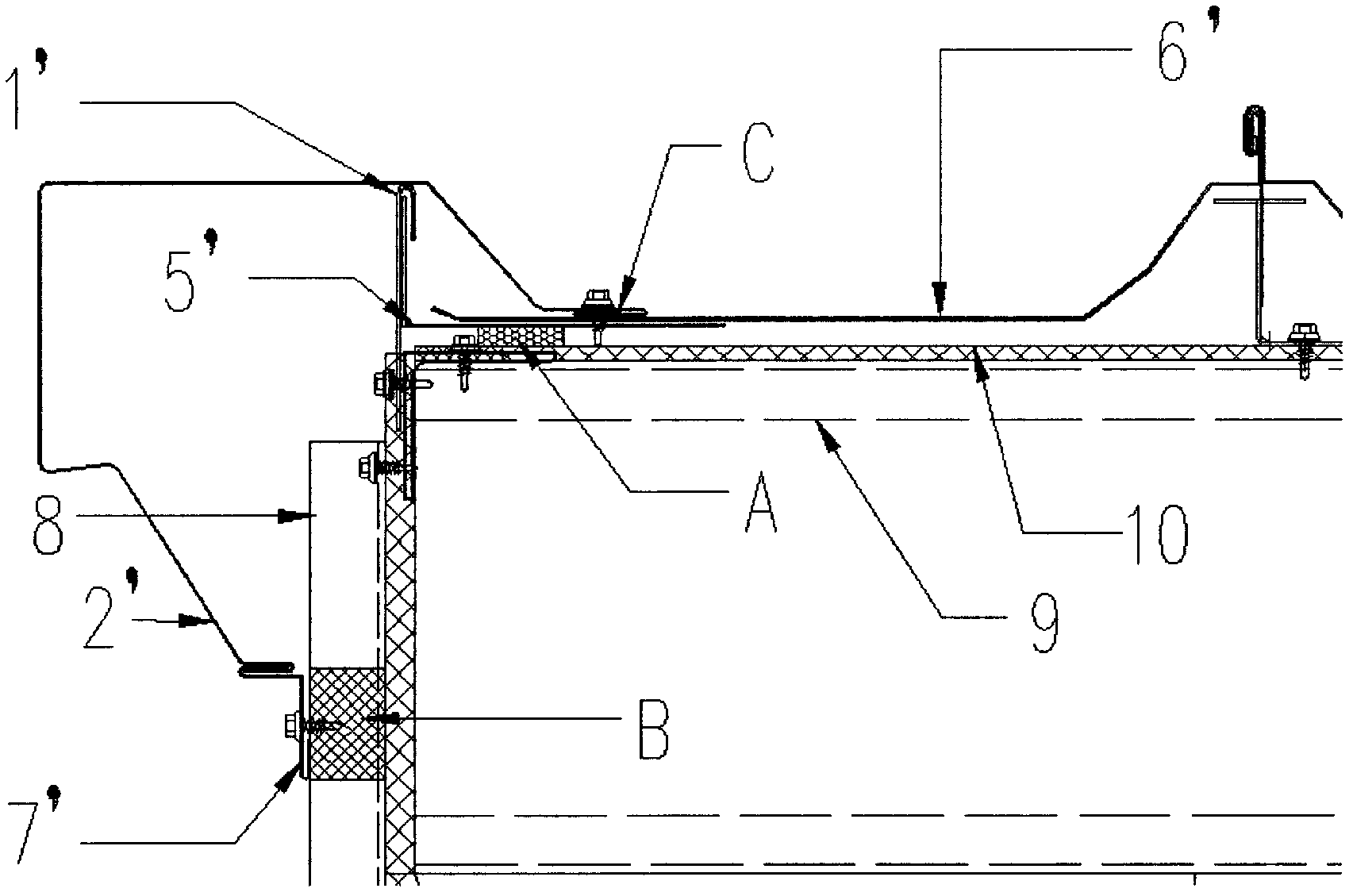

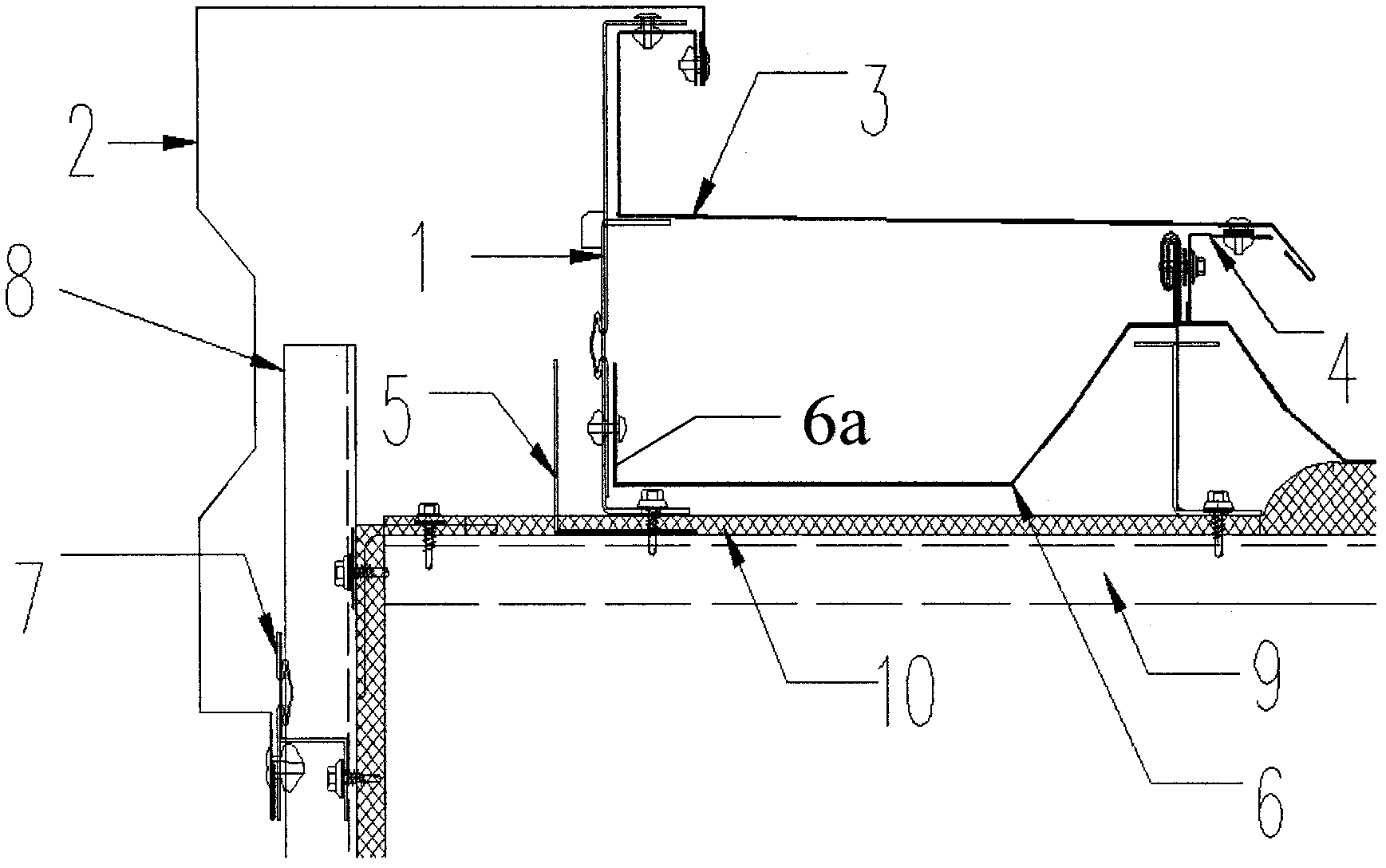

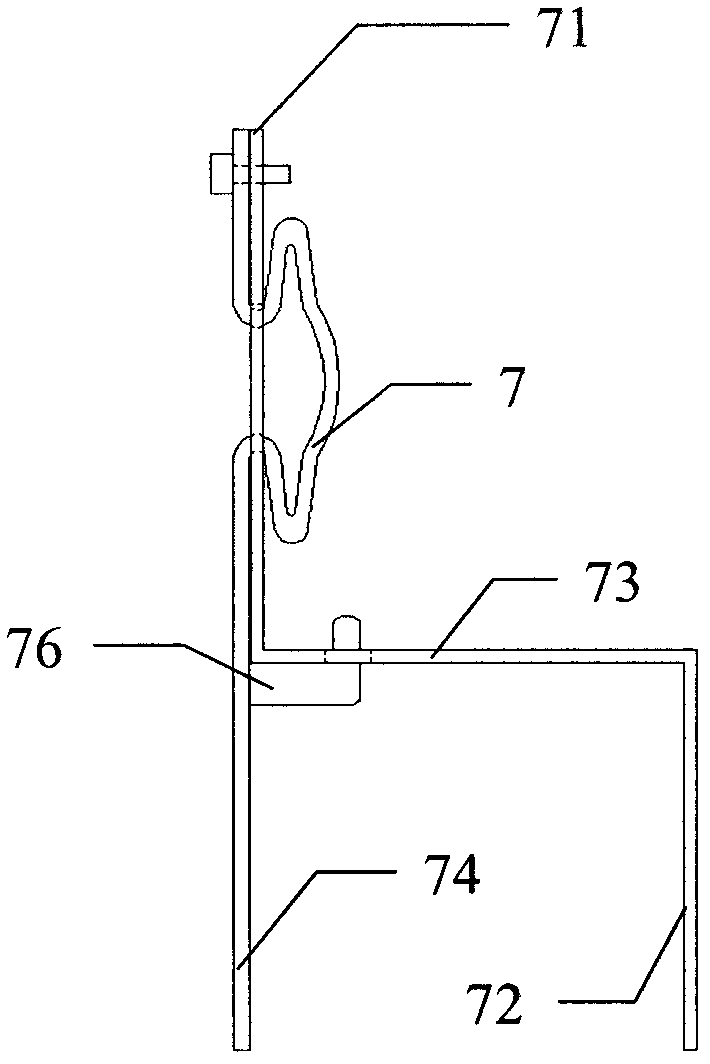

[0030] The gable side sliding roof panel rigid waterproof system described in this embodiment includes a gable roof sliding support 1, an outer flashing part 2, an inner flashing part 3, a flashing conversion part 4, a supporting angle steel 5, a hidden gutter 6, Wall-specific sliding bracket 7, exterior wall panels 8, roof purlins 9 and insulation layer 10, wherein the gable roof sliding bracket 1 includes a sliding bracket main body 11, a sliding piece 16, and the sliding piece 16 adopts 0.8mm hot-dip galvanized Plate, the main body 11 is made of 1.2mm hot-dip galvanized sheet, the width of the sliding piece is 50mm, and the maximum sliding stroke is 30mm; the distance between the main body support surface 12 and the base 15 is 80mm, which is 3mm higher than the top surface of the flashing conversion piece 4 to avoid water accumulation on the flashing part 3 in the gable; the distance between the top support surface 18 of the slide piece and the main support surface 12 is 2 m...

Embodiment 2

[0041] The gable side sliding roof panel rigid waterproof system described in this embodiment includes a gable roof sliding support 1, an outer flashing part 2, an inner flashing part 3, a flashing conversion part 4, a supporting angle steel 5, a hidden gutter 6, Wall-specific sliding bracket 7, exterior wall panels 8, roof purlins 9 and insulation layer 10, wherein the gable roof sliding bracket 1 includes a sliding bracket main body 11 and a sliding piece 16, and the sliding piece 16 adopts 0.7mm hot-dip plating Zinc plate, the main body 11 is made of 1.2mm hot-dip galvanized sheet, the width of the sliding piece is 60mm, the maximum sliding stroke is 40mm, the distance H between the main body support surface 12 and the base 15 is 85mm, which is higher than the top of the conversion flashing part 4 surface 3mm to avoid water accumulation on the flashing part 3 in the gable; the distance between the top support surface 18 of the slide piece and the main body support surface 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com