Method for oil displacement by activating indigenous microbes through slow release action

A technology of original microorganisms and oil displacement method, which is applied in the field of oil displacement where the slow release activates the original microorganisms, can solve the problems of continuous and stable nutrient supply to microorganisms, poor implementability, loss of nutrients, etc., and achieve Improve the affected area of water injection, reduce nutrient loss and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

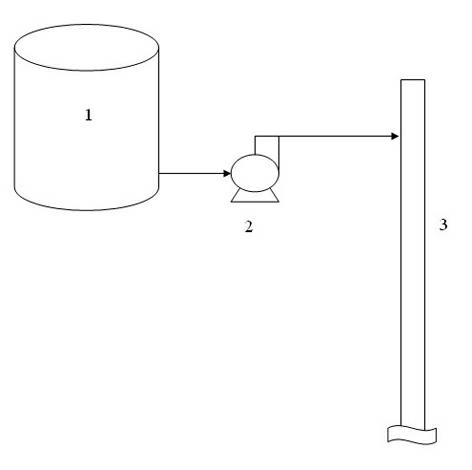

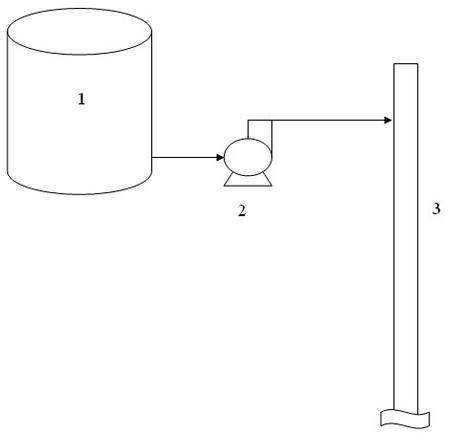

Image

Examples

Embodiment 1

[0025] The oil displacement method that the slow-release effect activates the original microorganisms includes the production and construction process of the slow-release nutrient microspheres:

[0026] The production method of slow-release nutrient microspheres: will contain 300kg sucrose, 50kg peptone, 30kgKH 2 PO 4 , 1% divinylbenzene, 1% BPO methyl acrylate solution suspended in 1 ton of water containing 1% sodium dodecylbenzenesulfonate and 0.5% gelatin at 40 °C (the volume of the oil phase and the water phase Ratio of 1:3), adjust the power of the ultrasonic emulsifier, after the size of the liquid beads is suitable and the particle size is uniform, the temperature is raised to 60°C at a speed of 5°C / 10min, polymerized for 2 hours, and the temperature is still raised to 85°C at the same speed, polymerized for 8 80-100nm nutrient microsphere preparations with varying drug loads were prepared within hours.

[0027] Process implementation: Suspend the slow-release nutrien...

Embodiment 2

[0029] The oil displacement method that the slow-release effect activates the original microorganisms includes the production and construction process of the slow-release nutrient microspheres:

[0030] The production method of slow-release nutrient microspheres: will contain 500kg sucrose, 50kg molasses, 30kgK 2 HPO 4 , 1% divinylbenzene, 1% BPO methyl acrylate solution suspended in 1 ton of water containing 1% sodium dodecylbenzenesulfonate and 0.5% gelatin at 40 °C (the volume of the oil phase and the water phase Ratio of 1:3), adjust the power of the ultrasonic emulsifier, after the size of the liquid beads is suitable and the particle size is uniform, the temperature is raised to 60°C at a speed of 5°C / 10min, polymerized for 2 hours, and the temperature is still raised to 85°C at the same speed, polymerized for 8 50-80nm nutrient microsphere preparations with varying drug loads were prepared within hours.

[0031] Process implementation: Suspend the slow-release nutrien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com