Positive pressure bundle pipe monitoring system for mine underground fire and toxic and harmful gases

A harmful gas and bundle tube monitoring technology, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems that the negative pressure bundle tube is easy to block and freeze, the negative pressure bundle tube is damaged, and the pipeline is flattened, etc. , to achieve accurate and reliable detection results, not easy to block the pipe, and achieve the effect of long transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described.

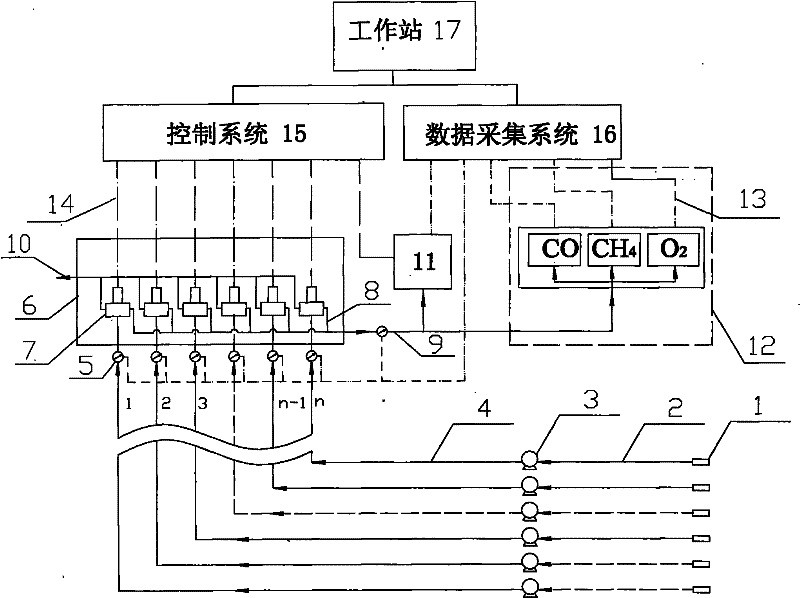

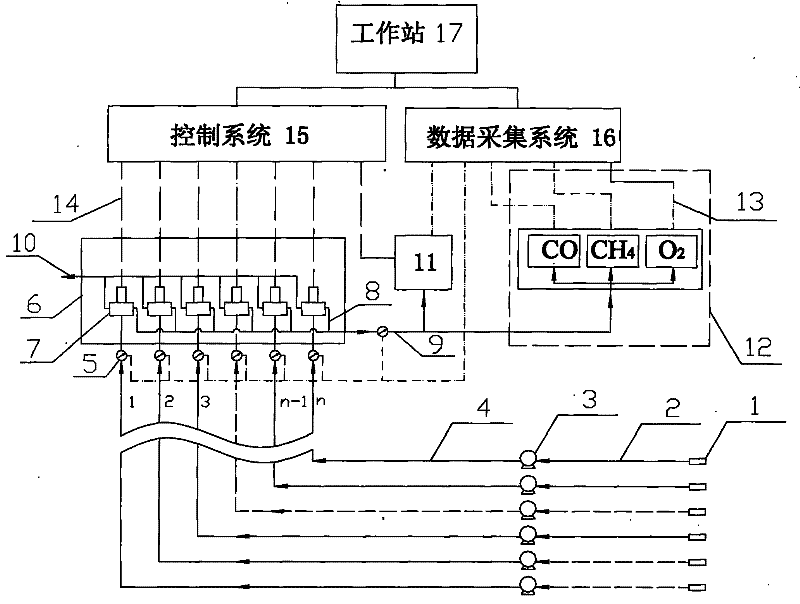

[0019] see figure 1 , mine underground fire and toxic and harmful gas positive pressure beam tube monitoring system, including gas positive pressure delivery system, gas analysis system, control system 15, data acquisition system 16 and workstation 17; The gas sucked in the pipeline 2 is pressurized and sent to the gas chromatograph 11 or a variety of gas concentration sensors 12 through the positive pressure gas supply pipeline 4 to analyze and detect the gas composition and concentration; Switch to make it enter the gas chromatograph 11 or multiple gas concentration sensors 12 one by one; the flow sensor 5 monitors the gas flow; the control system 15 controls the solenoid valve 7 and the gas chromatograph 11; the data acquisition system 16 pairs The flow sensor 5 , the gas chromatograph 11 or the data of various gas concentration sensors 12 are collected; the control system 15 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com