Exhaust gas recirculation (EGR) ratio measuring device

A technology for measuring devices and pipes, which can be used in measuring devices, transmittance measurement, color/spectral characteristic measurement, etc., and can solve problems such as adverse effects on measurement accuracy, longer piping length, and deterioration in responsiveness, so as to promote cost, reduce Pump capacity, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] One embodiment of the present invention will be described below with reference to the drawings.

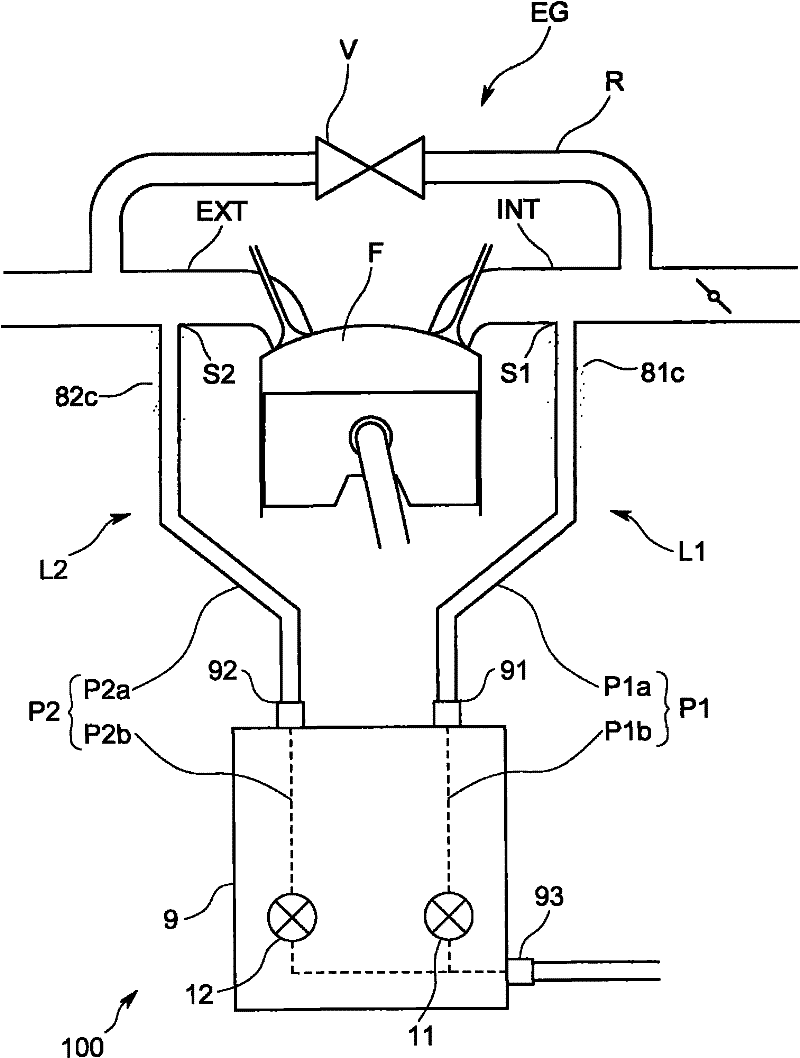

[0036] Such as figure 1 As shown, the EGR rate measurement device 100 of the present embodiment is based on the CO in the intake air introduced into the combustion chamber F of the internal combustion engine EG 2 Concentration and CO in the exhaust gas from the combustion chamber F 2 Concentration, measuring the EGR rate of the internal combustion engine EG.

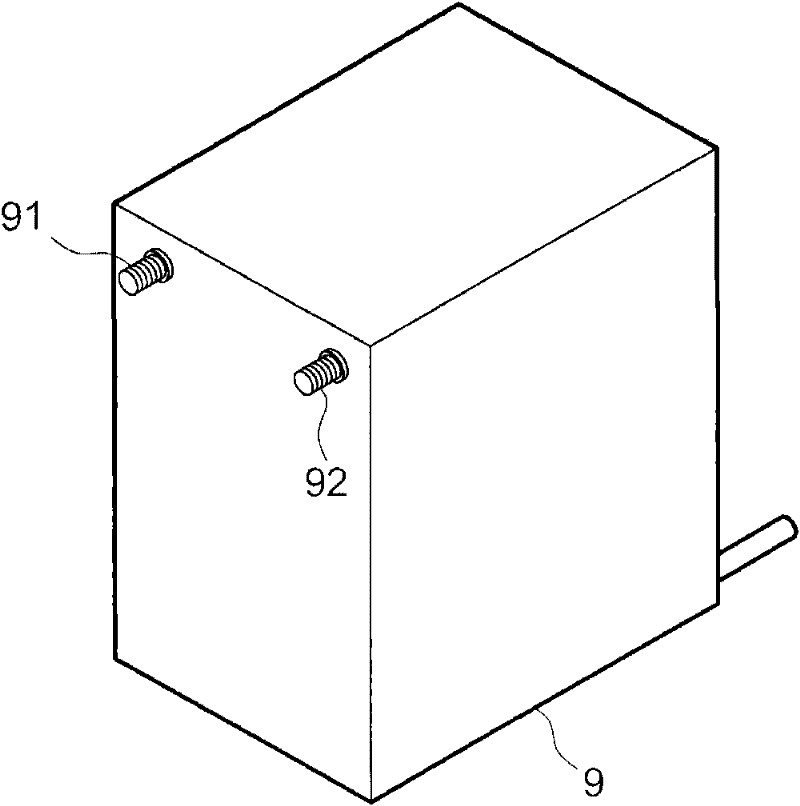

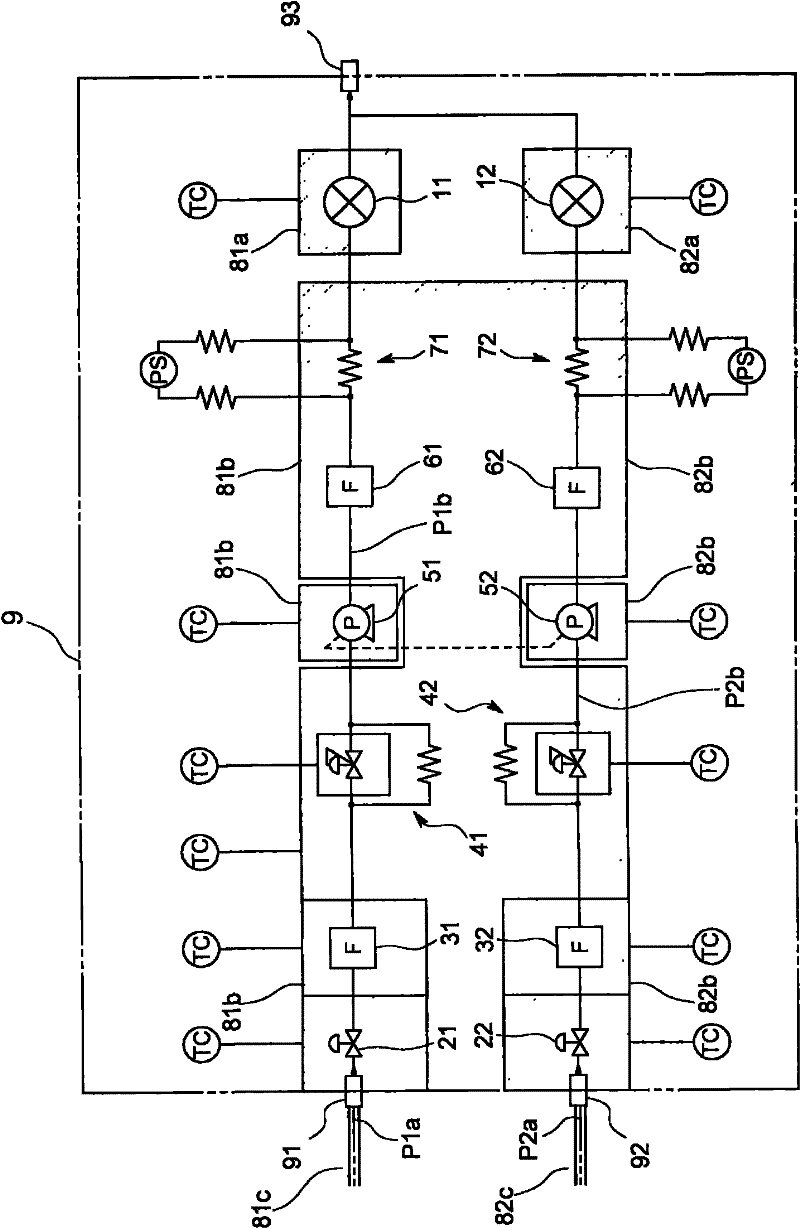

[0037] In more detail, the EGR rate measuring device 100 includes: measuring the CO in the intake air 2 Concentration of the first analyzer 11 and measure the CO in the exhaust 2 The second analyzer 12 of the concentration; the intake air introduction pipeline L1 is connected with the intake pipe INT of the internal combustion engine EG, and a part of the intake air is introduced into the first analyzer 11; the exhaust air introduction pipeline L2 is connected with the exhaust pipe of the internal combustion engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com