Method for detecting fault of coal bed methane collecting and delivering pipeline at coal mine region

A technology for fault detection and coalbed methane, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., and can solve problems such as low extraction concentration, blocked pipelines, and mine safety threats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

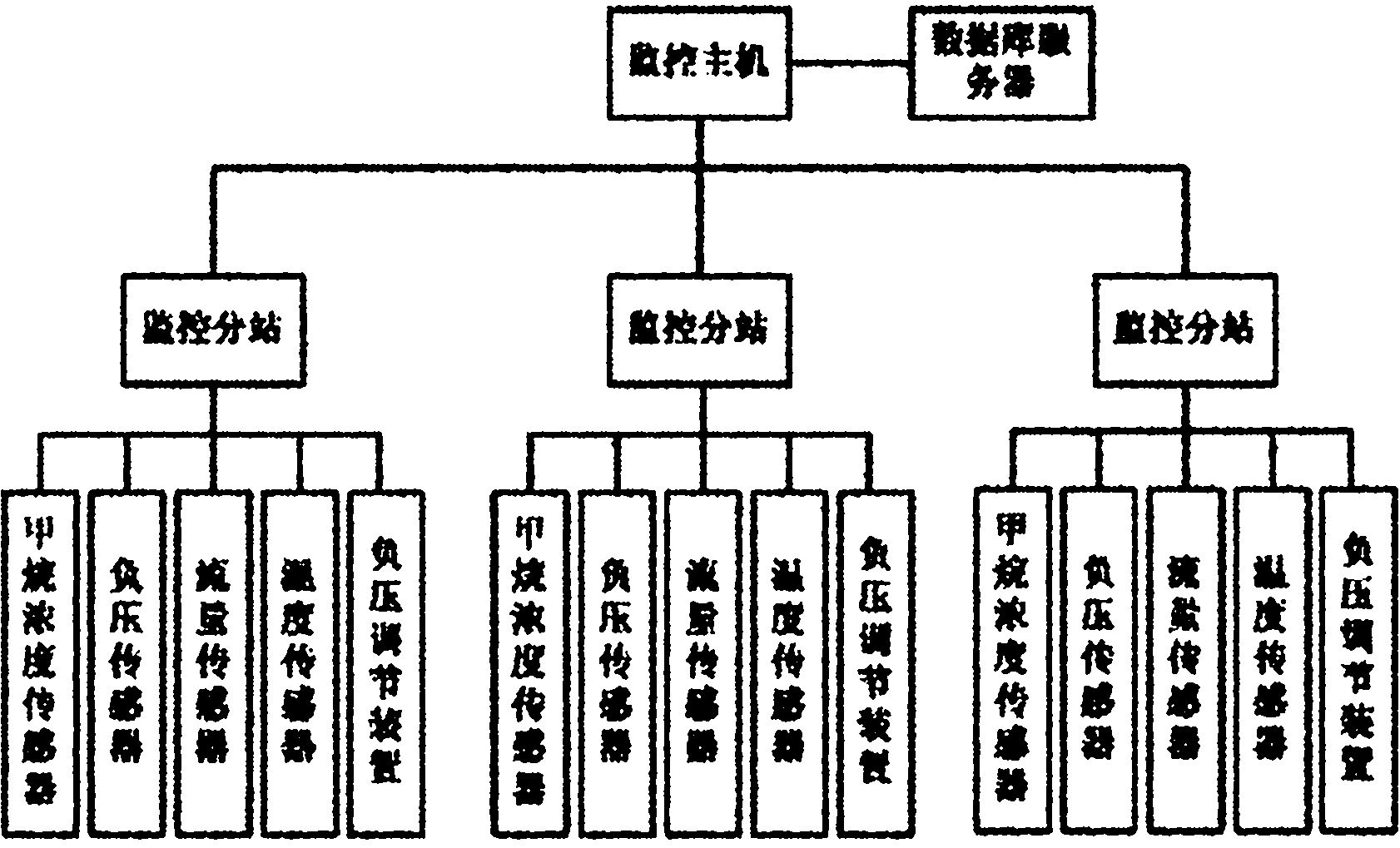

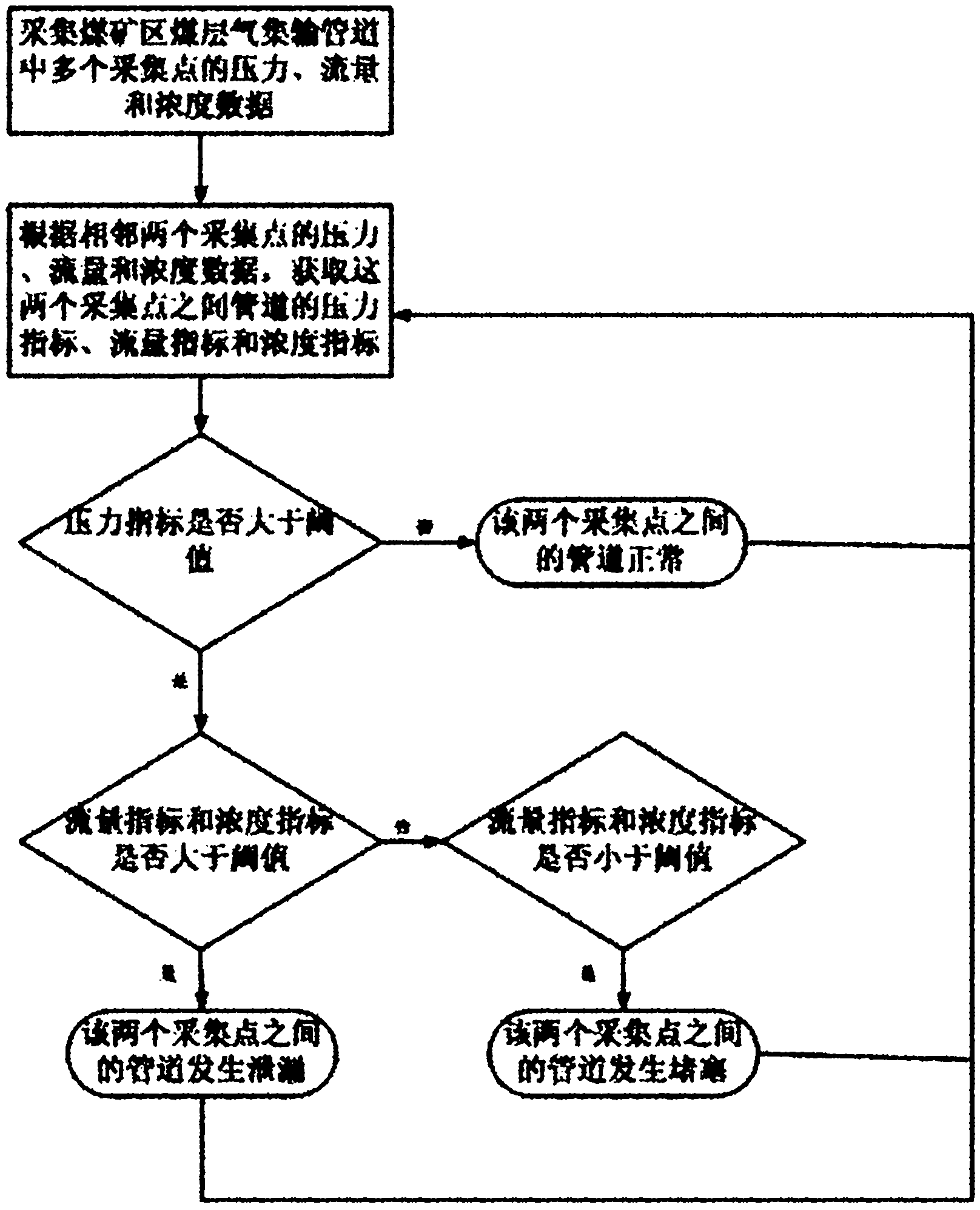

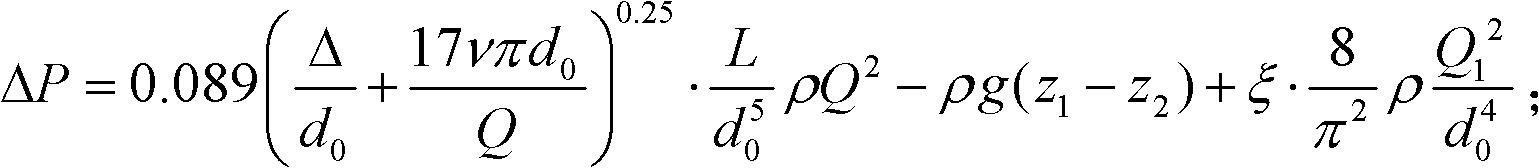

[0031] see figure 1 The coalbed methane gathering and transportation pipeline fault detection method in this embodiment can be realized by the following coalbed methane gathering and transportation pipeline fault detection system in the coal mining area. The coalbed methane gathering and transportation pipeline fault detection system in the coal mining area includes a monitoring host, Multiple monitoring sub-stations set in the coalbed methane gathering and transportation pipeline network in the coal mining area and multiple groups of methane concentration sensors, negative pressure sensors, flow sensors, temperature sensors and Negative pressure regulating device, each monitoring substation receives at least one group of methane concentration sensors, negative pressure sensors, flow sensors, and temperature sensors to collect methane concentration, negative pressure, flow and temperature data in the pipeline and transmit them to the monitoring host According to the monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com