Combustor assembly of multi-nozzle gas furnace for complete top air intake

A technology of burners and gas furnaces, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., which can solve the problems of not being too large, occupying a lot of space, and large volume of the burner, so as to achieve the effect of maintaining combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

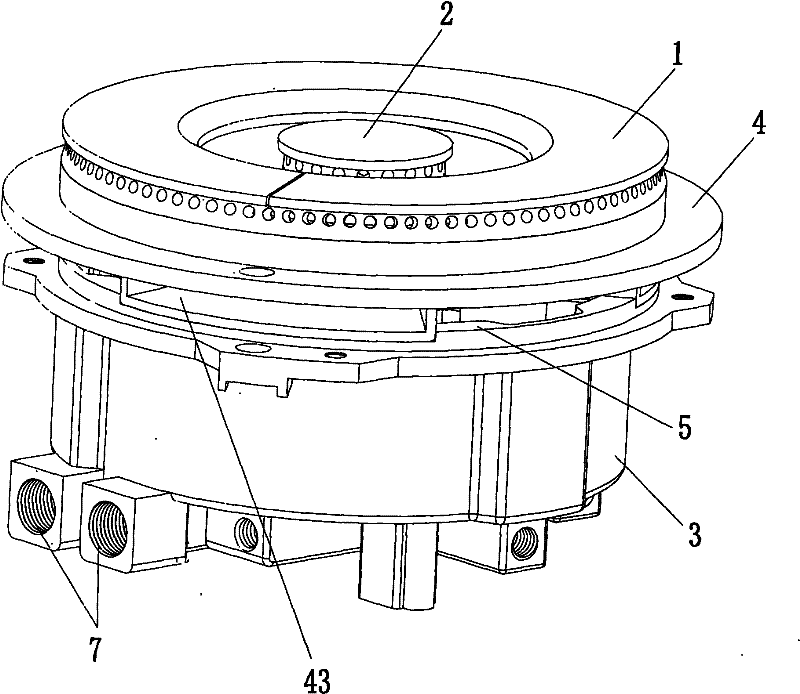

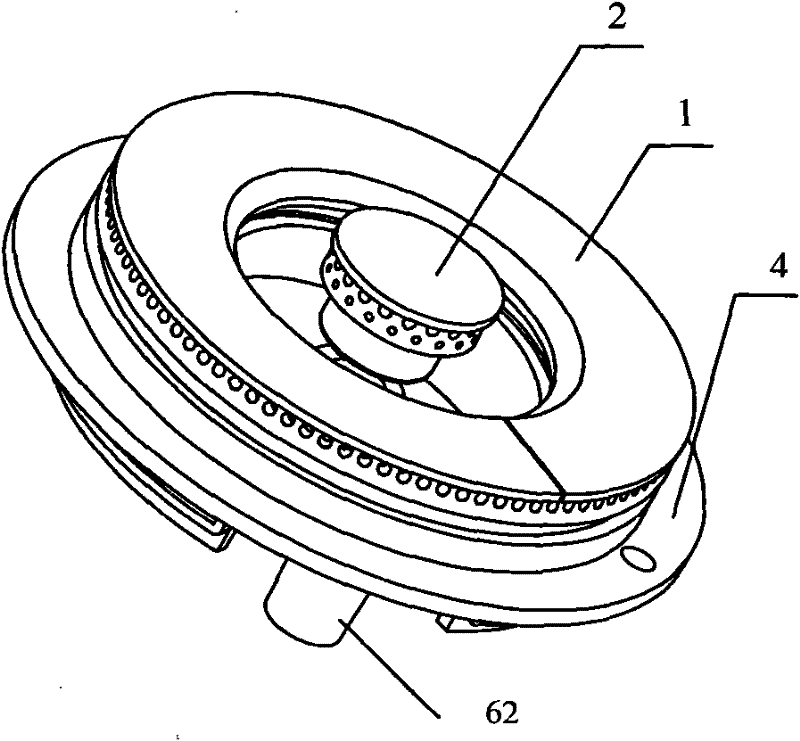

[0031] Such as figure 1 As shown, a multi-nozzle gas furnace burner assembly with upper air intake completely includes an outer ring fire cover 1, an inner ring fire cover 2, a cup-shaped base 3, and an upper seat cover 4 is arranged at the open end of the base 3.

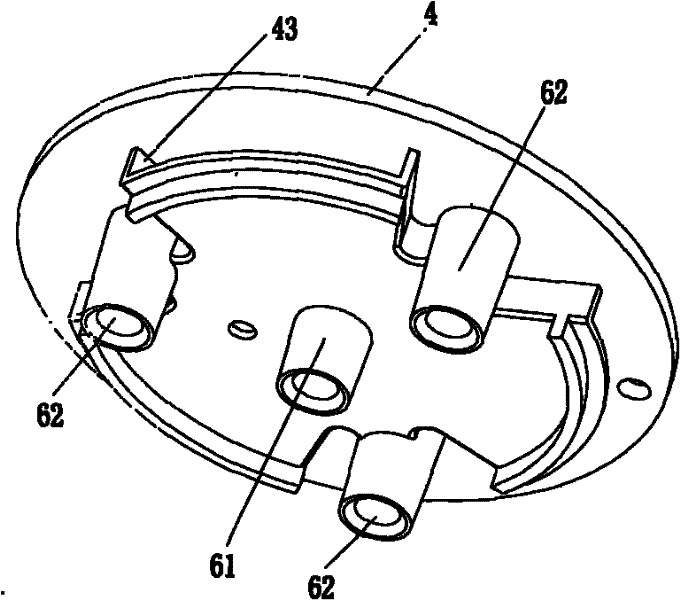

[0032] Such as figure 2 , image 3 and Figure 4 As shown, the upper end of the upper seat cover 4 is provided with an inner ring burner head 42 and an outer ring burner head 41, and the outer ring fire cover 1 and the outer ring burner head 41 form the main combustion chamber, and the inner ring fire cover 2 An auxiliary combustion chamber is formed between the inner ring burner head 42, the outer ring fire cover 1 is provided with an outer ring fire hole 11 communicating with the main combustion chamber, and the inner ring fire cover 2 is provided with an inner ring fire hole communicating with the auxiliary combustion chamber. Hole 21.

[0033] Such as figure 1 , image 3 , Figure 4 , Figure 5 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com