Urban garbage incinerating boiler

A municipal waste and incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of insufficient combustion of waste, low incineration temperature, heavy maintenance work, etc., to improve combustion efficiency, ensure environmental quality, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

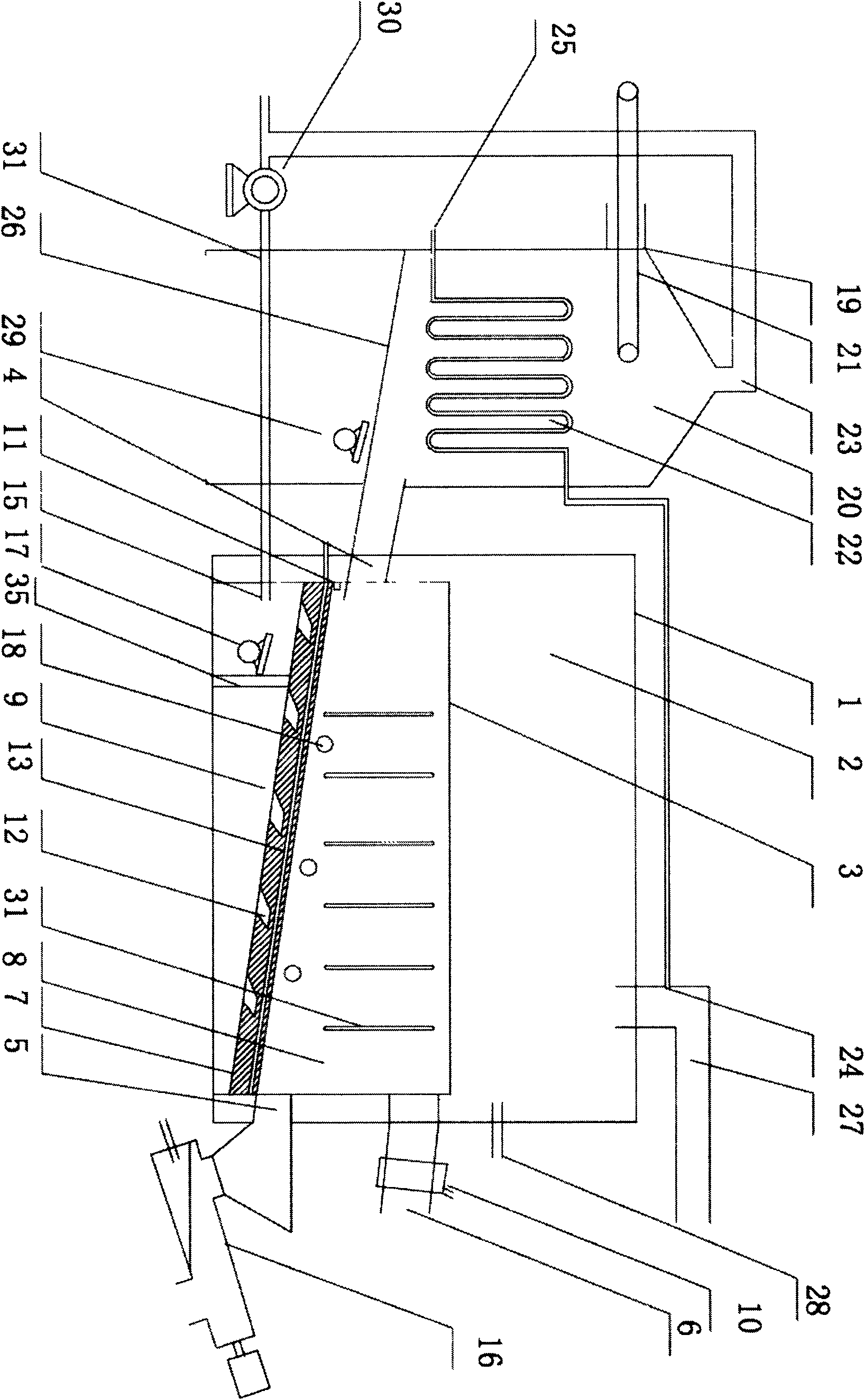

[0028] as attached figure 1 , Municipal waste incineration boiler, including boiler body 1, water tank 2, combustion chamber 3, feed port 4, slag outlet 5, water tank 2 is provided with steam pipe 27 and water inlet pipe 28 communicating with it.

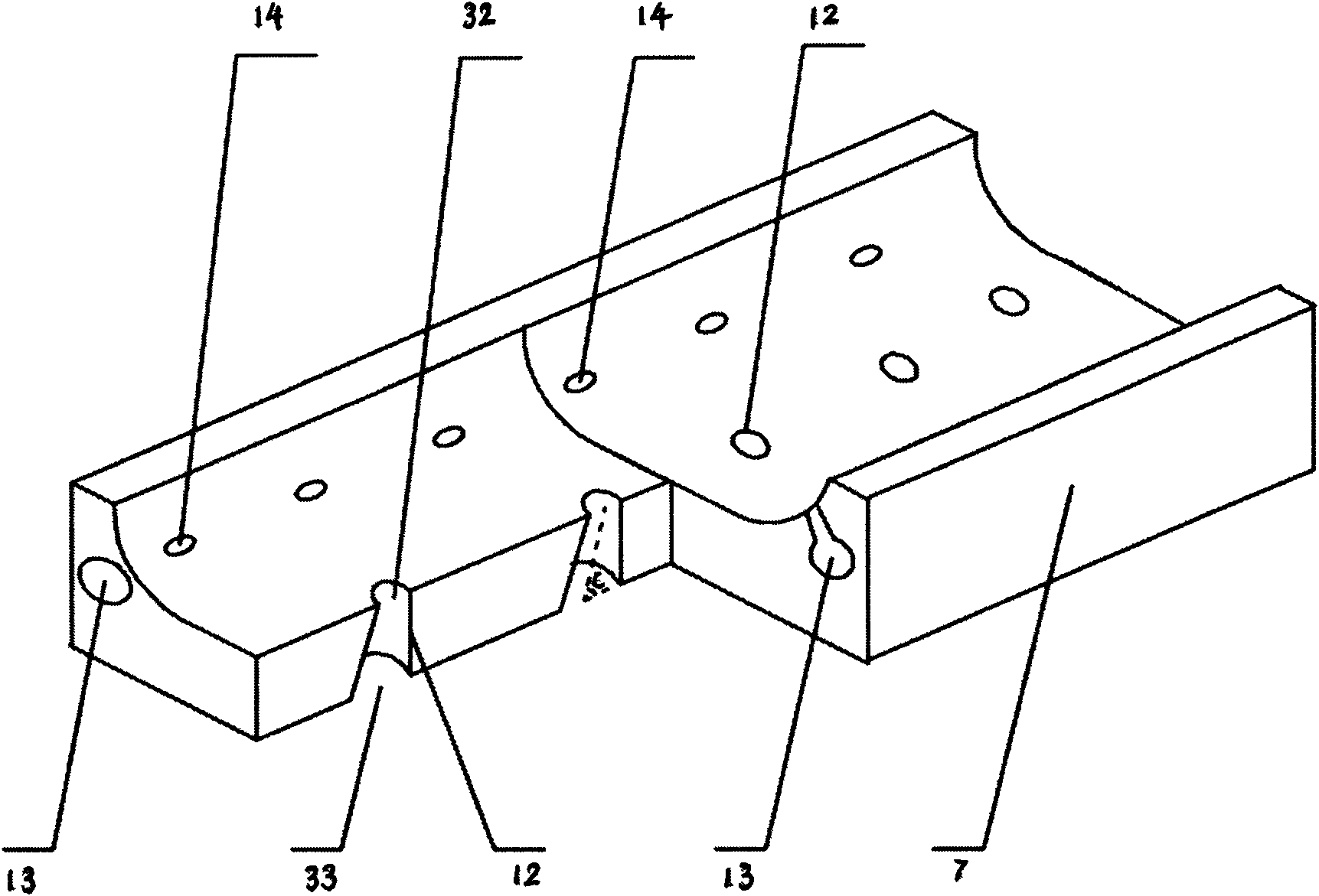

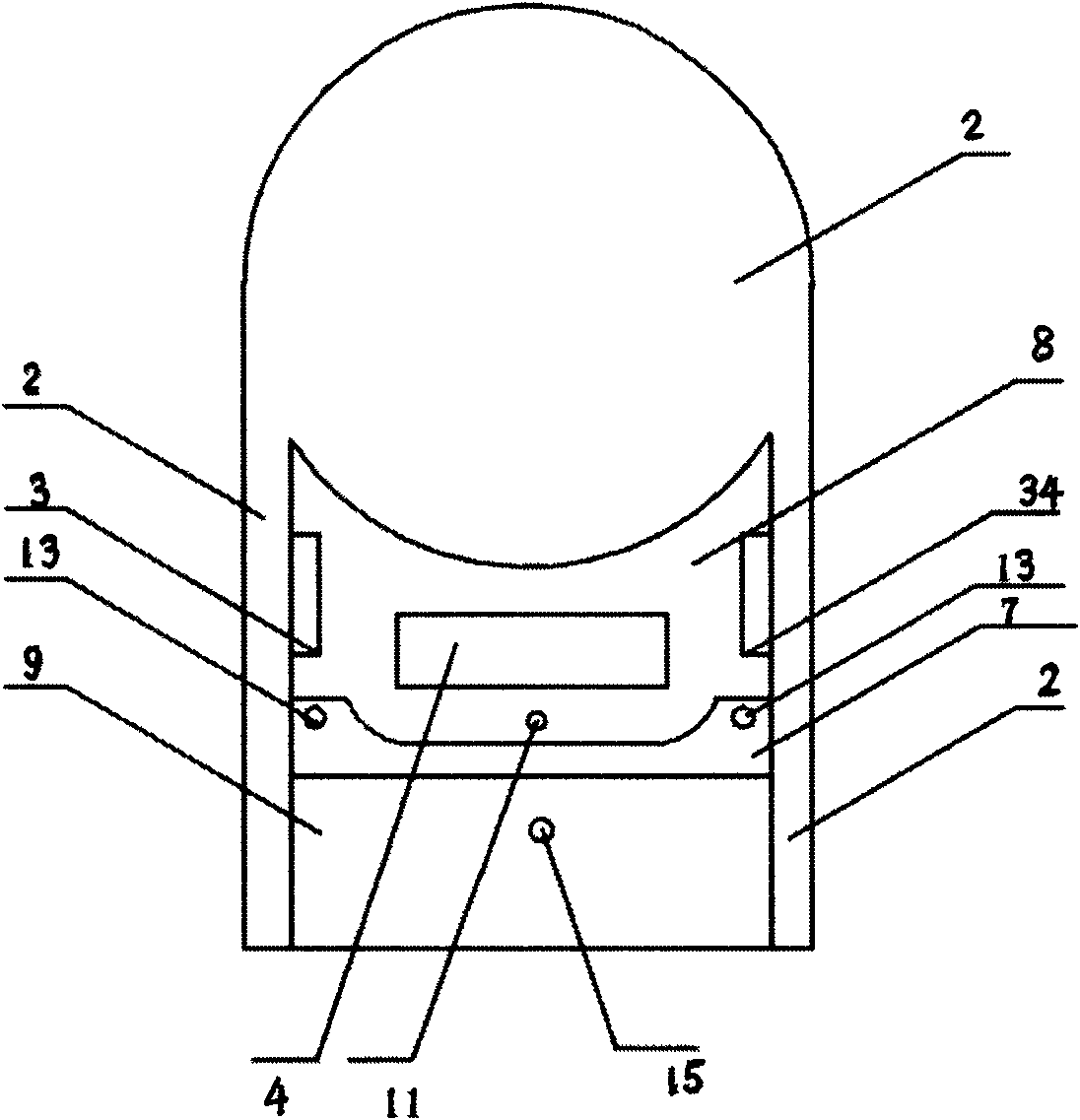

[0029] In the combustion chamber 3, there is an incineration plate 7 consistent with the width of the combustion chamber 3. The angle between the incineration plate and the horizontal plane is 25°. The incineration plate 7 is made of high-temperature ceramics and supported by a support frame 35. The incineration plate 7 separates the combustion chamber 3 into each Self-independent combustion chamber 8 and combustion chamber 9, combustion chamber 8 sidewalls and top are water tanks 2, combustion chamber 9 bottoms can be sealed with high-temperature rubber to ensure that mixed oxygen in combustion chamber 9 will not leak from combustion chamber. When the incineration board is installed, the screw jack can be used to adjust the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com