Hydrogen and oxygen combustion cooker based on oxyhydrogen production machine

A hydrogen-oxygen, oxygen-based technology, applied in gaseous heating fuels, heating fuels, household appliances, etc., can solve the problems of large heat transfer loss, high harmful emissions, low fuel combustion efficiency, etc., to improve combustion efficiency and reduce emissions , The effect of reducing heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present embodiment has carried out following experiment under civilian 220V power supply condition:

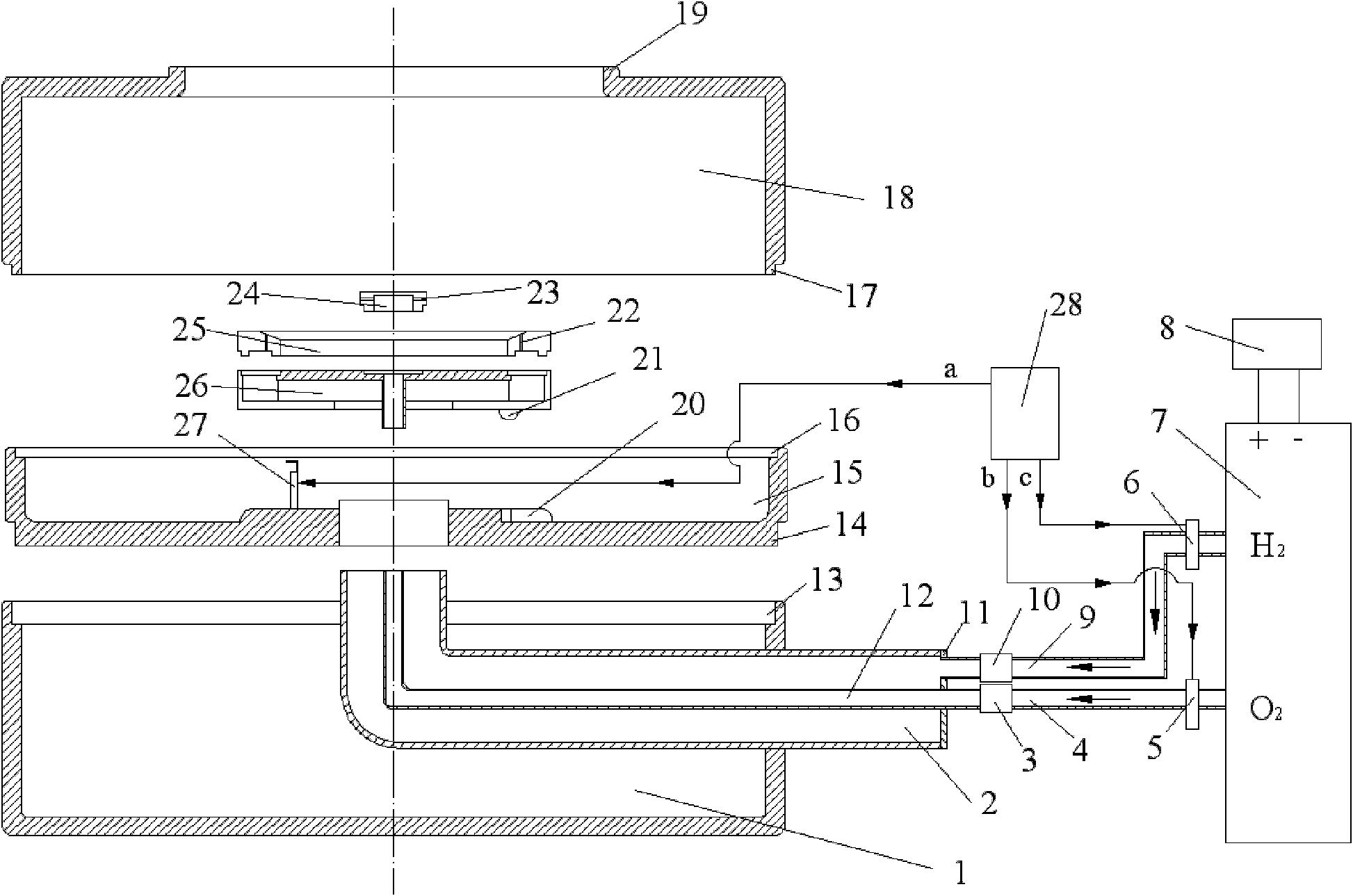

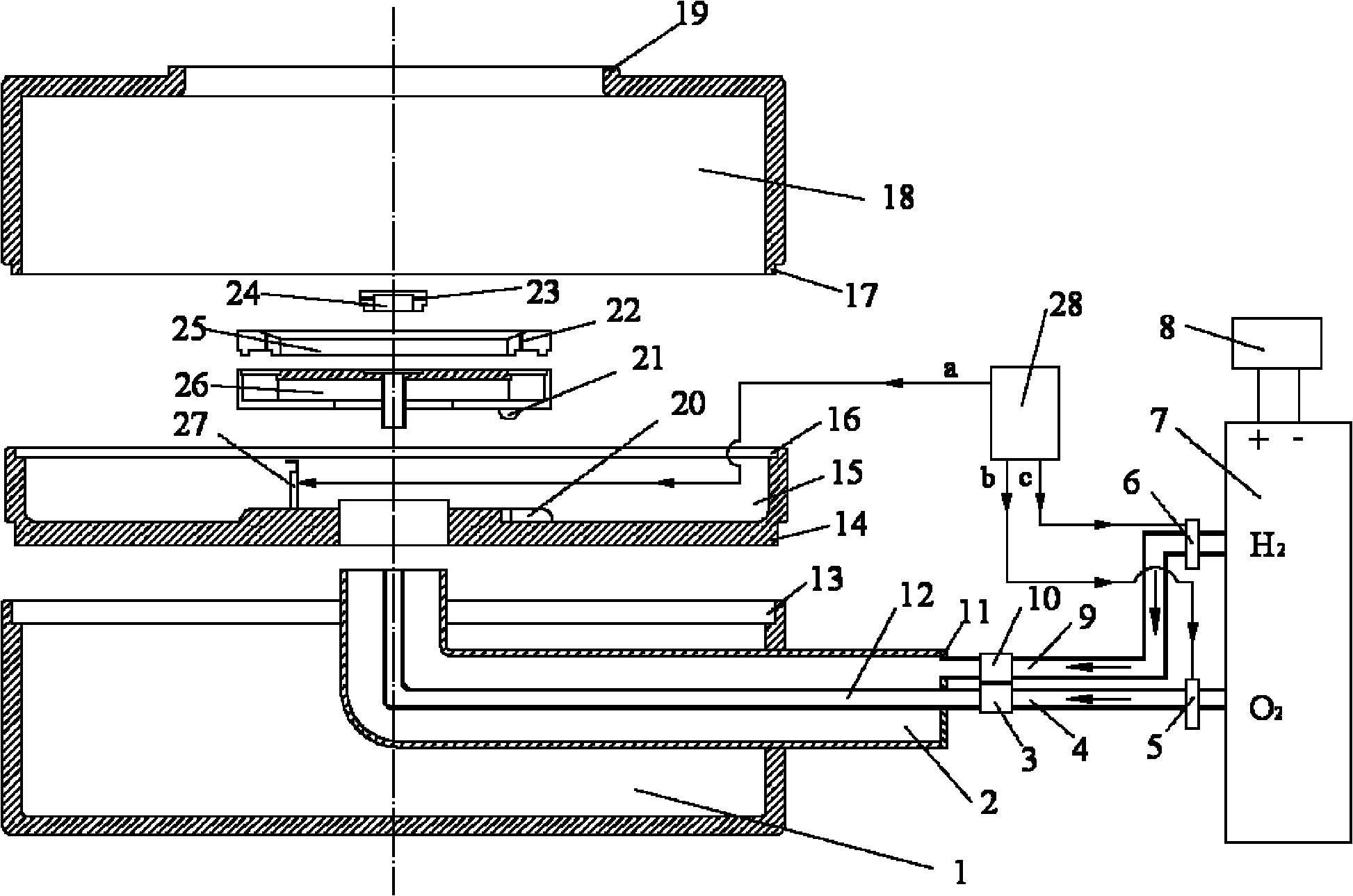

[0026] Before the experiment according to figure 1 The shown structure assembles the hydrogen-oxygen burner based on the hydrogen-oxygen generator.

[0027] Retaining the traditional cooker burner, including the burner positioning ball 21 on the burner head 26 and the burner head 26, the center fire cover 24 and the outer ring fire cover 25 respectively installed on the burner head through the positioning ring, through the positioning hole Ignition pin 27 that is inserted in cooker base 1 and near outer ring fire cover 25, the injection hole on the original center fire cover 24 is used as oxygen injection hole 23, and the injection hole on the original outer ring fire cover 25 is used as hydrogen injection hole 22. On the basis, a set of hydrogen and oxygen production and supply devices and a set of ceramic heat-insulated cooker devices are added;

[0028] Describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com