Explosion-proof grading anti-blocking type solid drying system

A drying system, explosion-proof technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of changing the particle size distribution of raw materials, destroying the particle size of dried materials, and complex equipment structure. The effect of shortening drying time, ensuring unobstructed sieve holes and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

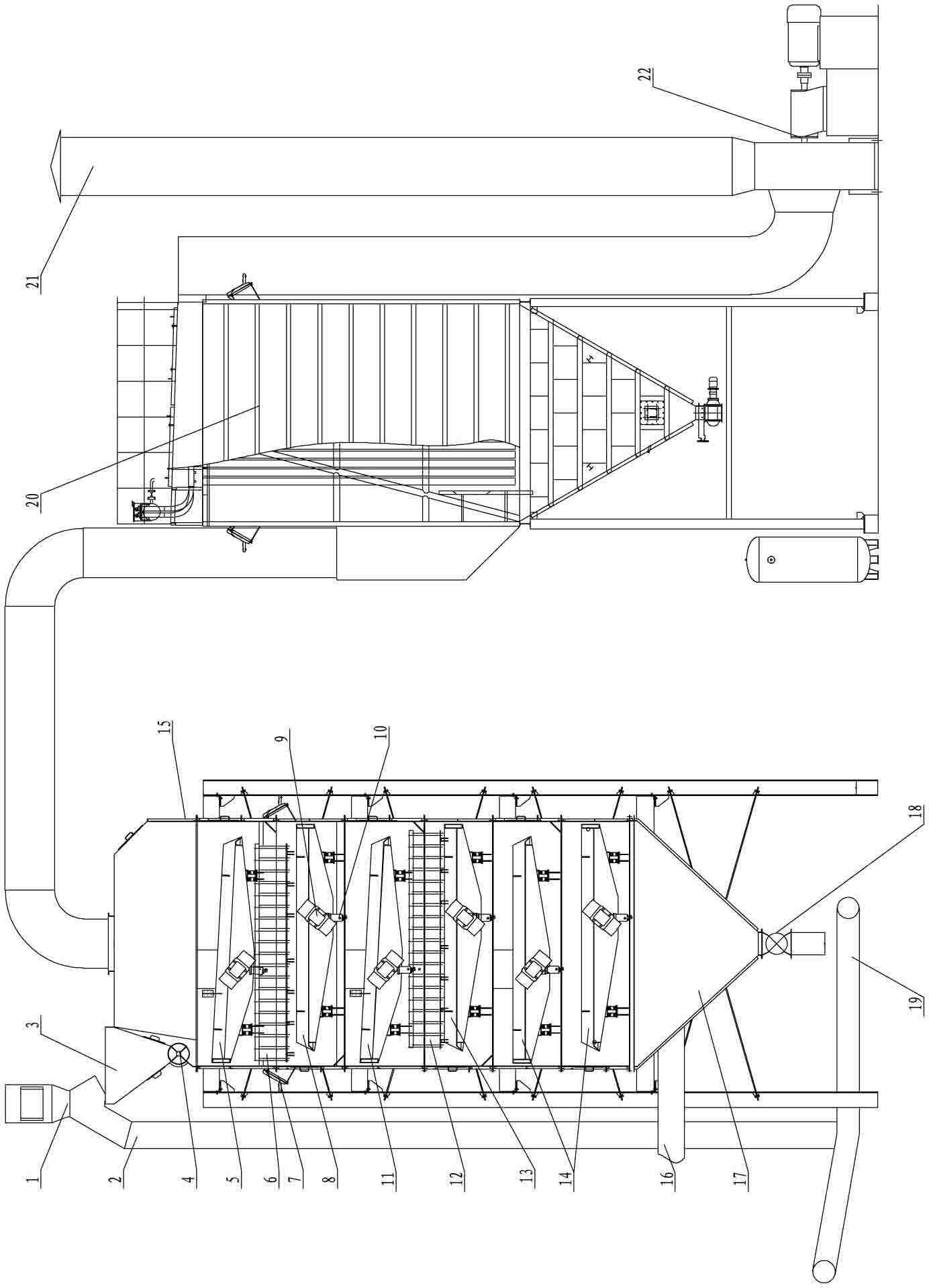

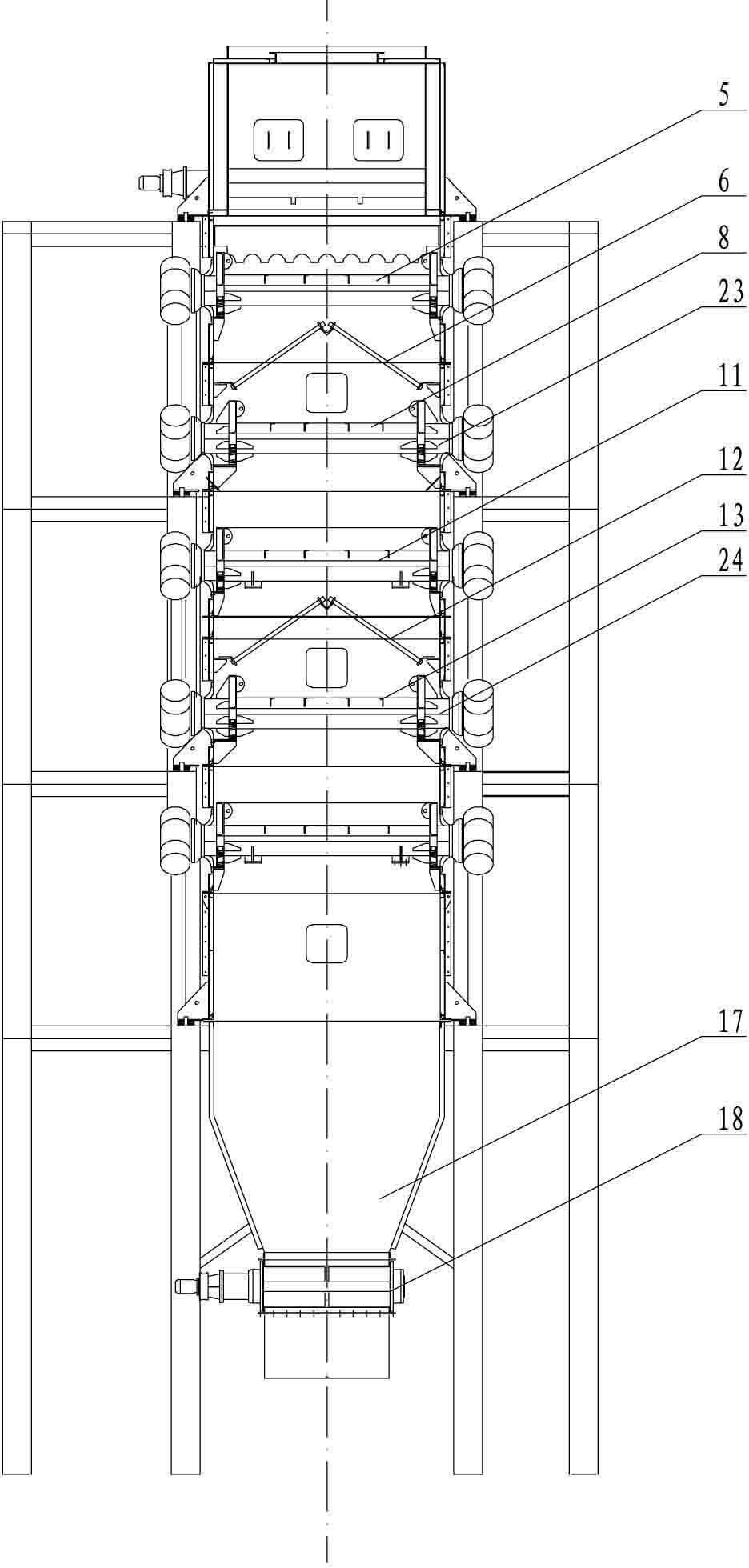

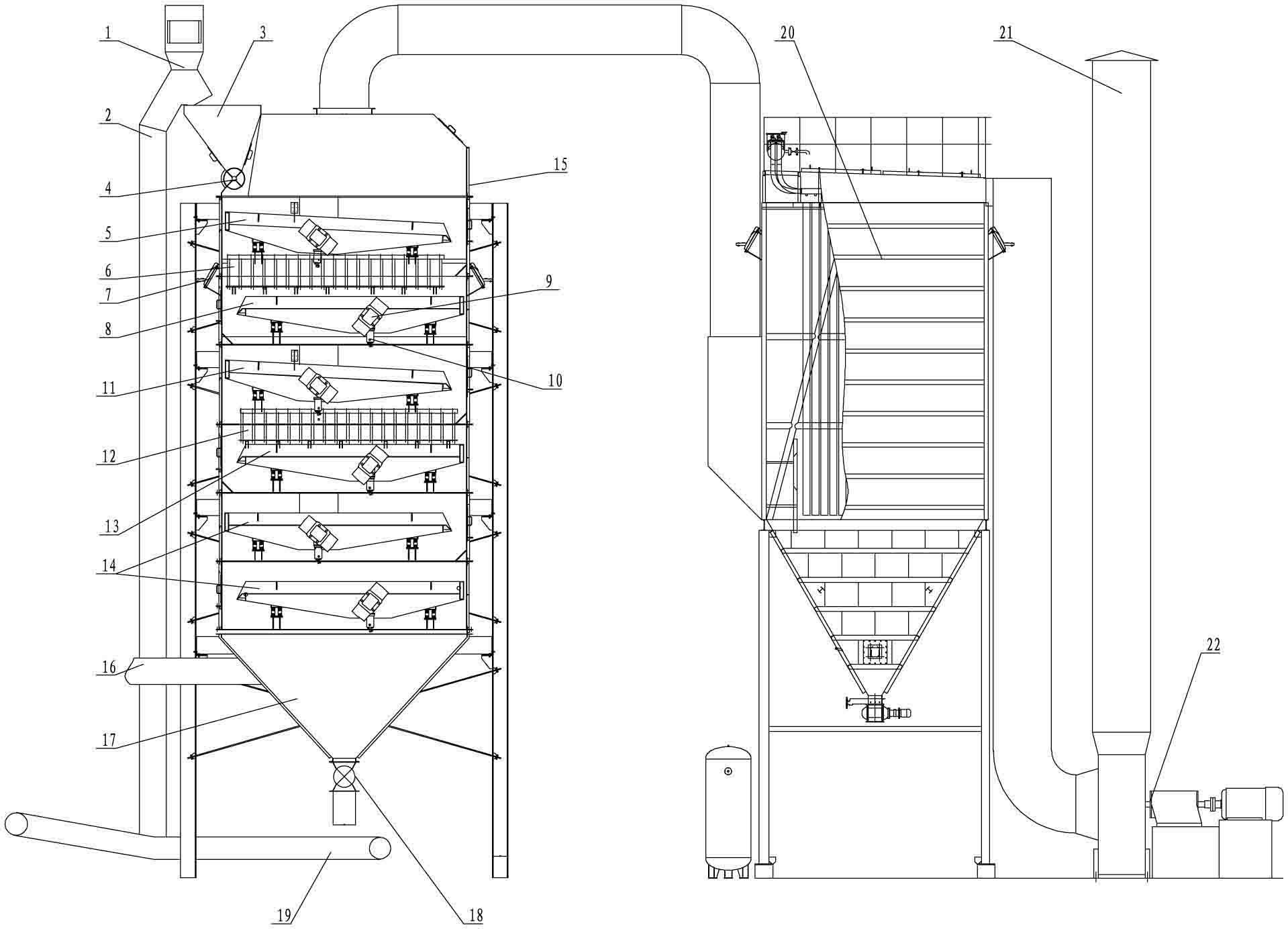

[0009] Such as Figure 1 ~ Figure 2 As shown, the explosion-proof graded anti-blocking solid drying system: the three-way reversing valve (1) is connected to the bypass system (2) and the storage bin (3) respectively, and the storage bin (3) passes through the inlet discharge valve ( 4) Communicate with the inside of the casing (15).

[0010] Inside the housing (15), install the distribution vibrating feeder I (5), the under-screen material diverting device I (6), the large particle material preheating vibrating feeder I (8), and the distributing vibrating feeder from top to bottom. Feeder II (11), under-sieve material diversion device II (12), large particle material preheating vibrating feeder II (13) and two-layer material drying vibrating feeder (14); cloth distributing vibrating feeder I (5), material distribution vibrating feeder II (11), large particle material preheating vibrating feeder I (8), large particle material preheating vibrating feeder II (13) and material d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com