Testing device and method for simulating backflow of propping agent

A testing device and proppant technology, which is applied in the fields of mining fluid, earthwork drilling, geophysical measurement, etc., can solve the problems that cannot reflect the real situation of proppant backflow, do not consider the influence of proppant backflow, and cannot simulate proppant backflow Influence and other issues, to achieve the effect of practical test method, good adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

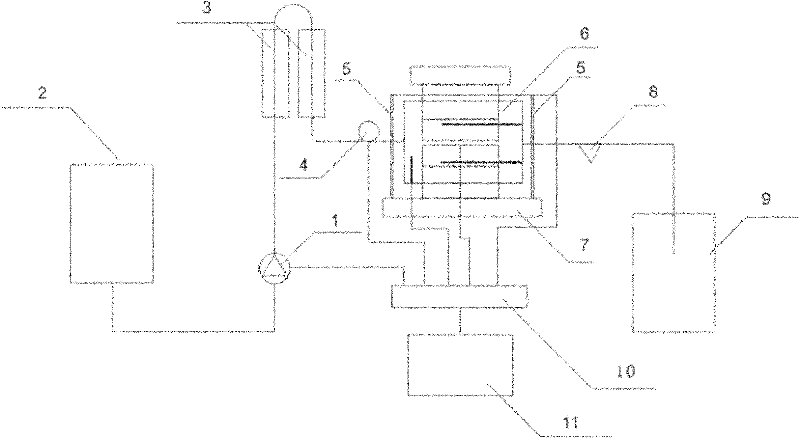

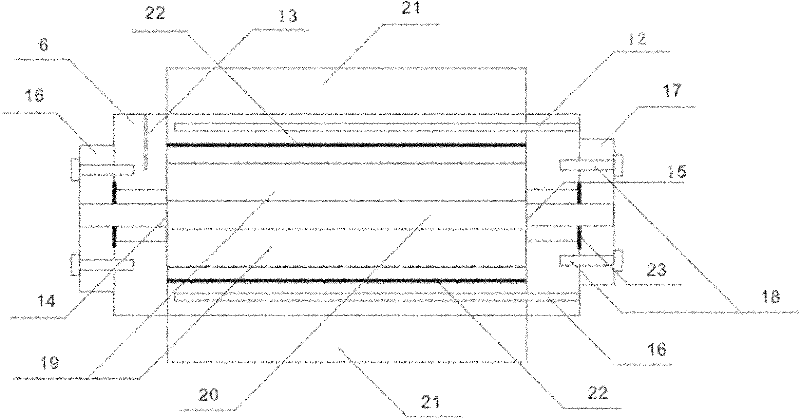

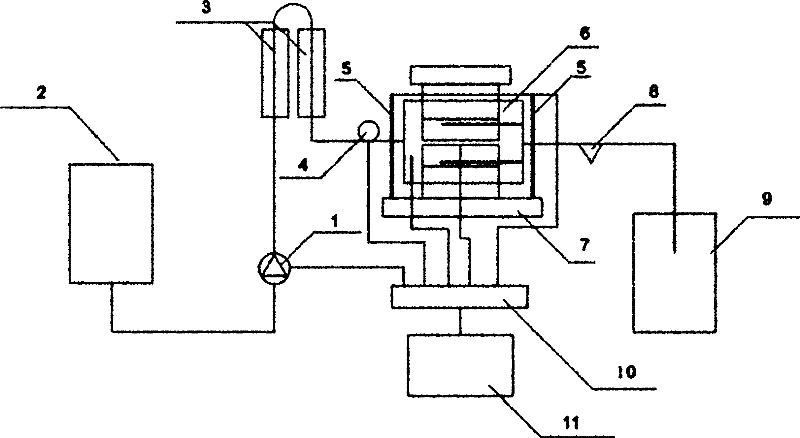

[0036] Further illustrate the present invention according to accompanying drawing below.

[0037] see figure 1 , figure 2 .

[0038] A test device for simulating proppant reflux, mainly composed of a liquid storage tank 2, a chamber pump 1, a pipeline heating jacket 3, a flow meter 4, a diversion chamber 6, a displacement sensor 5, a hydraulic press 7, a sand sample collector 8, a waste A liquid tank 9, a data acquisition control board 10, and a computer 11 are formed; the inside of the diversion chamber 6 has a deep hole for inserting an electric heating rod 12 and a temperature sensor 13; Between the plates 19 is a proppant laying area 20; the upper and lower parts of the diversion chamber 6 are connected with the hydraulic press 7 by a piston 21 and sealed by a sealing ring 22; the two ends of the diversion chamber 6 have a liquid inlet hole 14 and a liquid outlet hole respectively 15; the liquid inlet hole 14 is sequentially connected to the front joint 16, the flow me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com