Method for optimizing and setting regulator parameters of coordinated control system

A technology for coordinating control systems and regulators, applied in general control systems, control/regulation systems, adaptive control, etc., to achieve fast power response speed and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

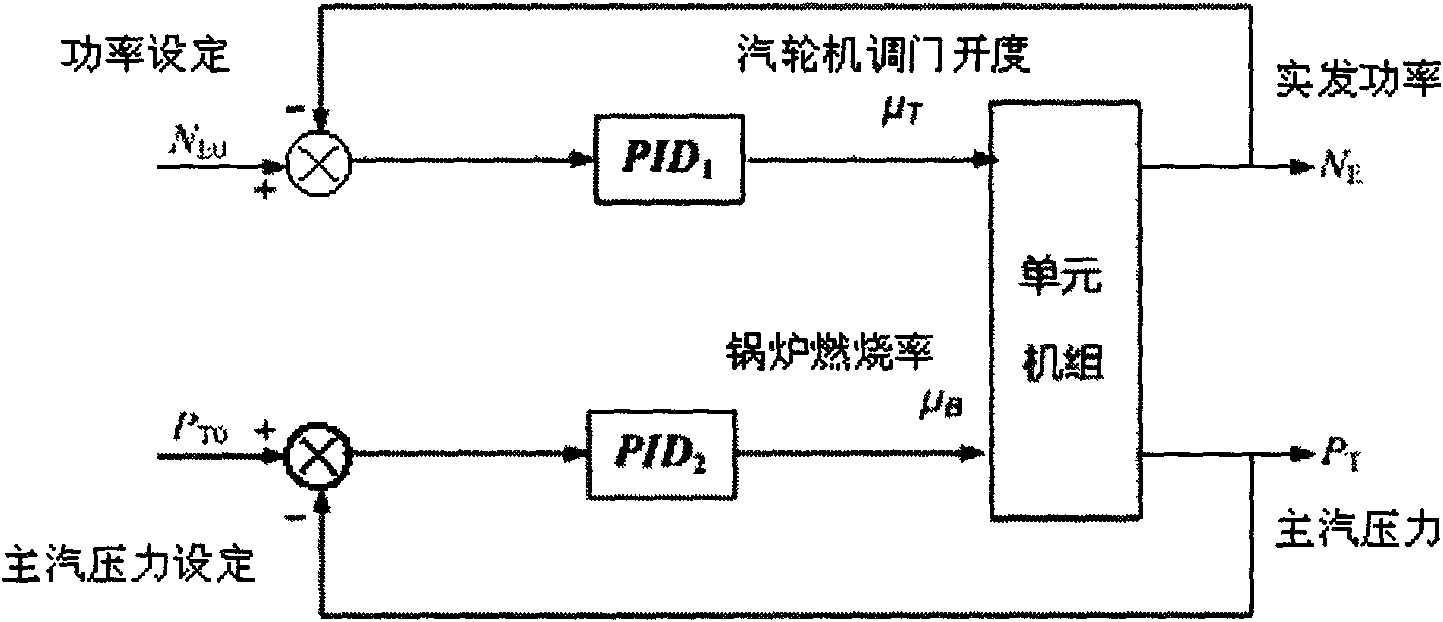

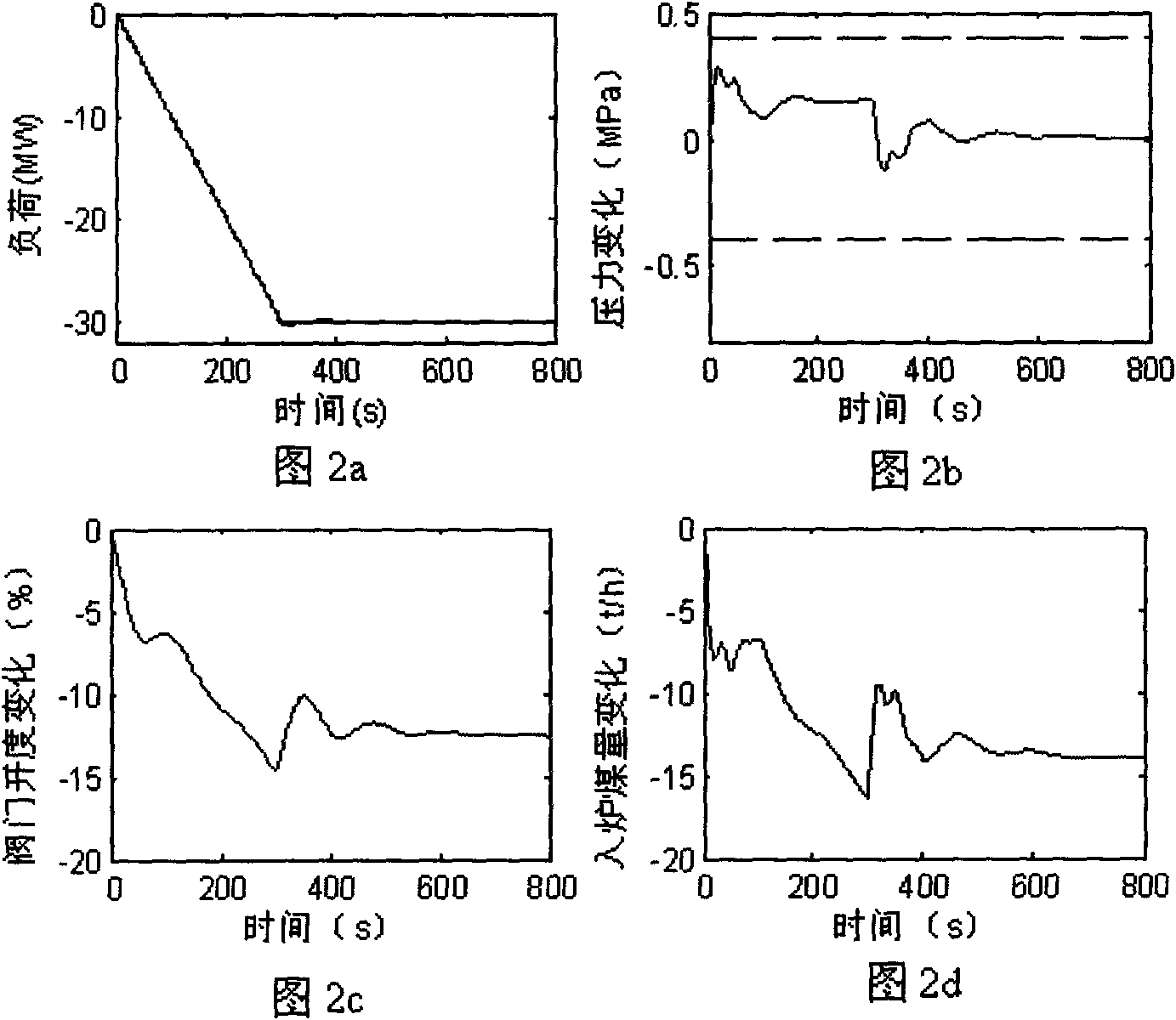

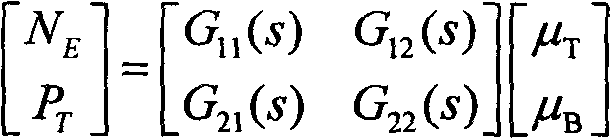

[0025] The coordinated control system of unit units is a 2×2 multivariable system, and the optimal setting of proportional-integral-derivative (PID) regulator parameters is essentially a multi-objective optimization problem. First of all, the mathematical model of the controlled object in unit unit coordinated control must be obtained, and then several optimization targets for proportional-integral-derivative (PID) regulator parameter optimization are determined according to the characteristics of the boiler following coordinated control system. Then, through the control system simulation, the multi-objective genetic algorithm is used to optimize the parameters of the proportional-integral-derivative (PID) regulator, and a set of optimal solution sets is obtained. Finally, the preference decision is made, and a group of parameters are selected from the optimal solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com