Driving device for cold cathode lamp tube powdering machine

A transmission device and cold cathode technology, applied in transmission device, mechanical equipment, tube/light screen manufacturing, etc., can solve the problems of inability to ensure the consistency of the thickness of the powder layer on the tube wall, large light decay, and low luminous efficiency of the lamp tube. Achieve the effect of strong practicability, energy saving and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

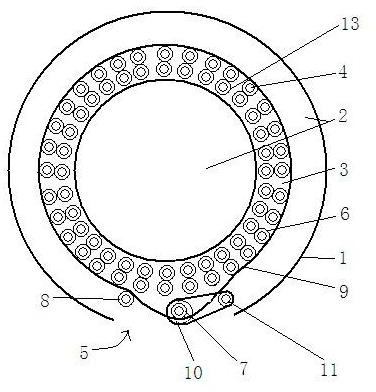

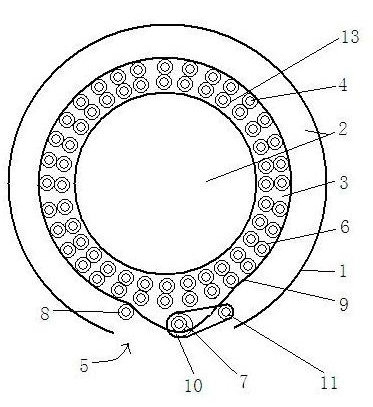

[0017] Such as figure 1 As shown, the present invention includes a track 3 located in the shell 1 of the powder feeder and revolving around the center of the shell (the track 3 runs in the heating channel 2 in the shell), a chuck connected to the track 3 through a shaft 4, and also includes The operating window 5 provided on the casing 1.

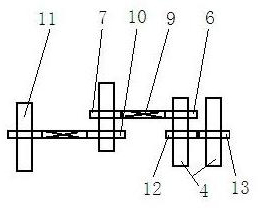

[0018] Such as figure 1 , 2 As shown, the chuck shaft 4 connected to the track 3 has two inner and outer circles, and the shaft 4 of the chuck of the outer ring is provided with a first transmission wheel 6 and a second transmission wheel 12, and the first transmission wheel 6 is connected with the transmission belt 9 through The driving wheel 7 is connected for transmission, and the second transmission wheel 12 is meshed with the third transmission wheel 13 on the inner ring shaft for transmission. The shaft 4 of the chuck is rotatably connected to the track 3 (the rotatable connection can be a bearing connection or a sleeve connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com