Continuously controllable transformer

A transformer and side column technology, applied in the field of continuously controllable transformers, can solve the problems of slow response speed and inability to continuously adjust the voltage, and achieve the effects of fast response speed, continuously adjustable voltage and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

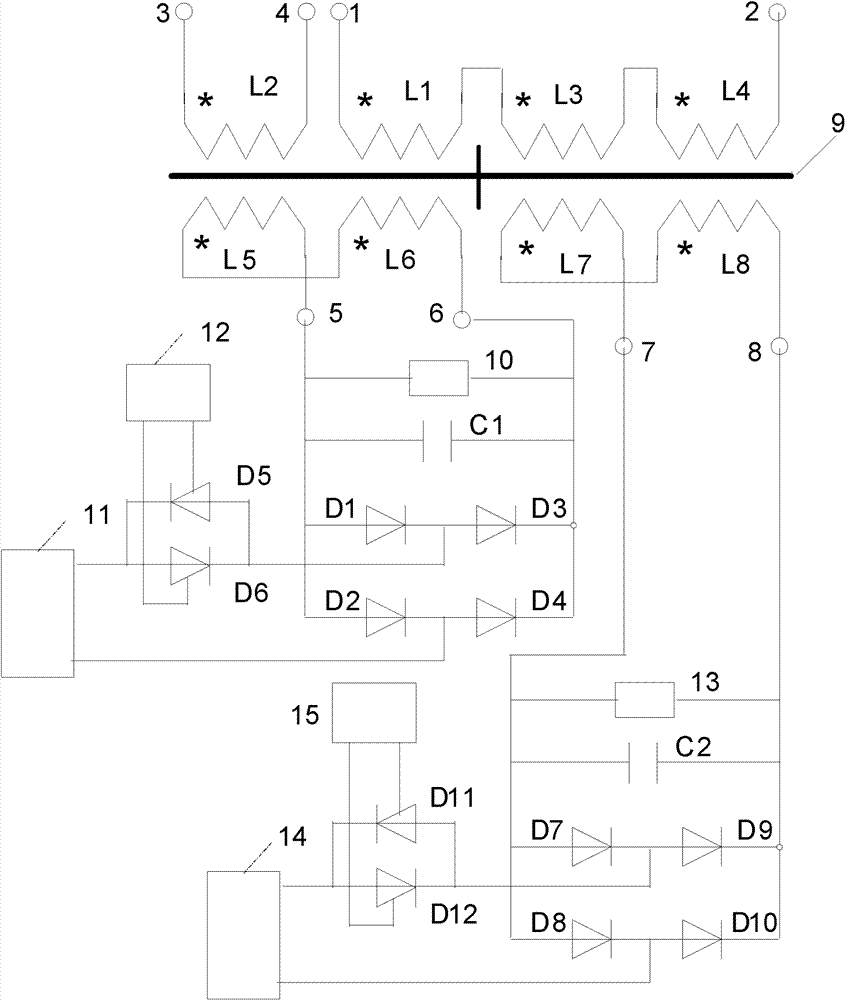

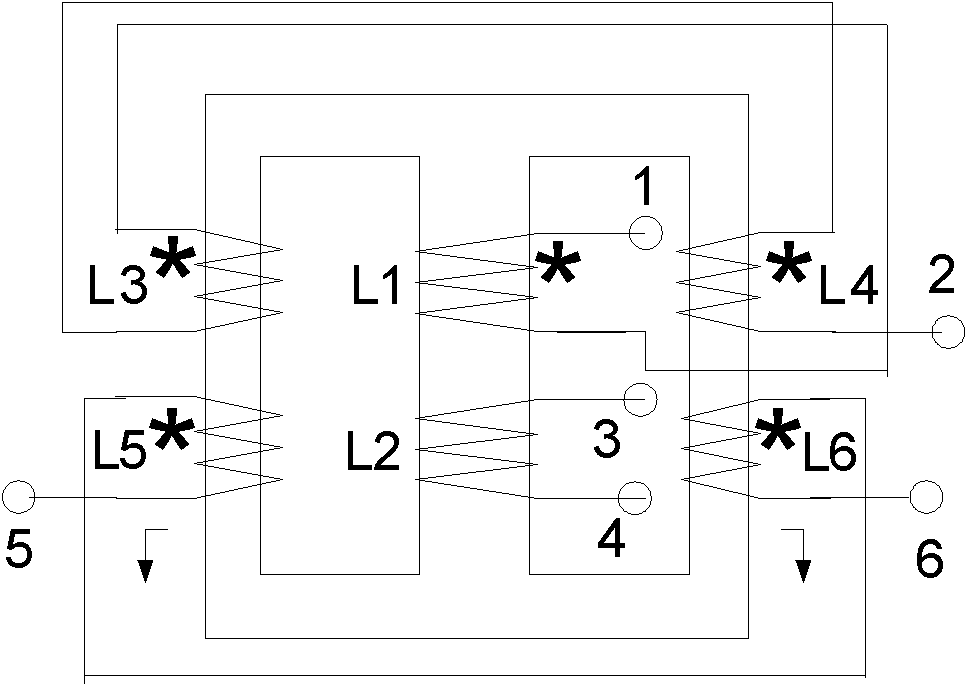

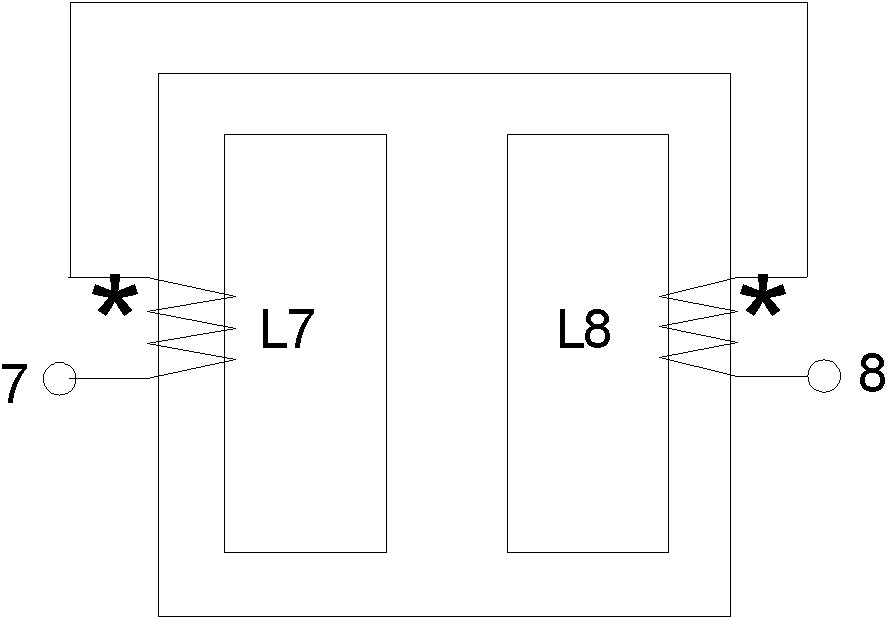

[0027] The topology and connection mode of a continuous controllable transformer are as follows: figure 1 shown. Figure 2a is the front view of the main core of the continuous controllable transformer; Figure 2b is a side view of the main core of the continuous controllable transformer; Figure 2c It is a top view of the main core of the continuous controllable transformer. The iron core of the continuous controllable transformer has 5 pillars, one center pillar and four side pillars. The five pillars are parallel to each other and arranged in a cross shape; the two ends of the five pillars have cross-shaped beams to form a magnetic flux circuit, and the side pillars I, The beams of the central column and side column II are on one straight line, the beams of side column III, central column, and side column IV are on another straight line, and the two straight lines are perpendicular to each other at the axis of the central column; side column I, side column II are respect...

Embodiment 2

[0048] In this embodiment, the number of turns of the AC coil L1 is equal to the number of turns of the AC coil L3.

[0049] When the current of the DC coil L5 and the DC coil L6 of the continuous controllable transformer is zero, and the current of the DC coil L7 and the DC coil L8 is also zero. The output voltage of the AC coil L2 is zero.

[0050] When the current of the DC coil L5 and the DC coil L6 of the continuous controllable transformer is zero, and the current of the DC coil L7 and the DC coil L8 increases from zero. The output voltage of the AC coil L2 increases from zero to half of the maximum output voltage.

[0051] When the current of the DC coil L5 and DC coil L6 of the continuous controllable transformer gradually decreases from the maximum to zero, and at the same time, the current of the DC coil L5 and the DC coil L6 gradually increases from zero to the maximum, the output voltage of the AC coil L2 is output from the maximum Half of the voltage ramps up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com