Novel polyvinyl chloride resin plasticiser

一种聚氯乙烯树脂、酯类增塑剂的技术,应用在聚氯乙烯树脂组合物,聚氯乙烯树脂的增塑剂领域,能够解决应用减少等问题,达到抗拉强度改善、良好塑化效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] Hereinafter, the present invention will be described in more detail with reference to examples. However, these examples are only for illustrating the present invention, and the scope of the present invention is not limited thereto. In these examples, the following methods were used to evaluate the physical properties of the samples.

[0043] hardness

[0044] Based on ASTM D2240, the measuring needle of the hardness tester (type A) is completely pressed on a certain point of the sample for 5 seconds, and then the hardness of the sample is measured. The hardness test was carried out at three points of each sample, and then the average value thereof was obtained. The hardness is used as an index to express the plasticizing efficiency.

[0045] Tensile Strength, Elongation, Modulus of Elasticity at 100% Elongation

[0046] Based on the ASTM D412 method, UTM was used to measure the tensile strength and elastic modulus of the samples. The tensile strength and modulus...

Embodiment 1

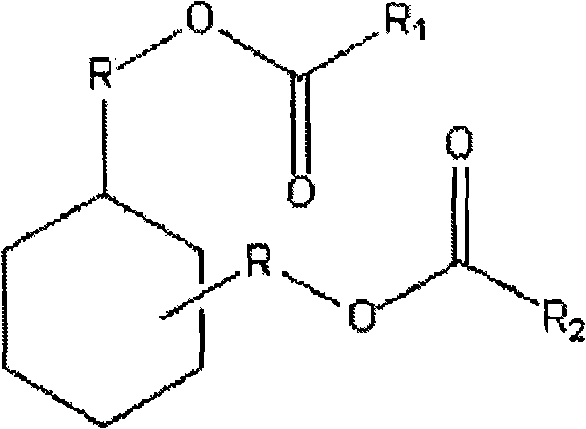

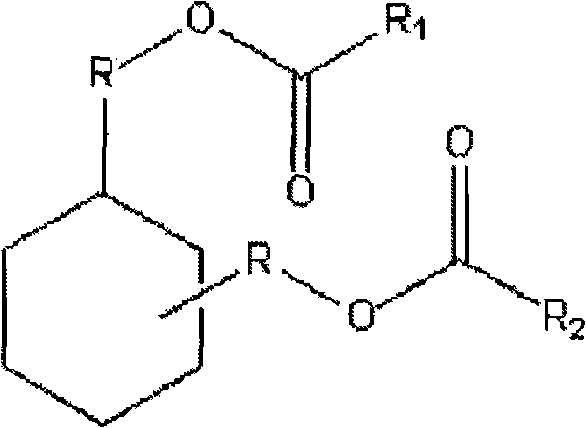

[0050] Preparation of Ester Plasticizers Using 1,4-Cyclohexanedimethanol, Benzoic Acid and 2-Ethylhexanoic Acid

[0051] First, 1.0 mol of 1,4-cyclohexanedimethanol, 0.6 mol of benzoic acid, 1.2 mol of 2-ethylhexanoic acid, 200 g of toluene (as a solvent) and 3.0 g of sodium bisulfate (as a catalyst) were placed in a A 2L round bottom flask with a stirrer and a condenser, then heated to 100°C, and reacted for 12 hours.

[0052] After the reaction, the pressure was reduced to 5 mmHg with a vacuum pump at 200° C., the unreacted organic acid was neutralized with a 10% by weight aqueous sodium carbonate solution, washed with water, dehydrated, and then filtered with an adsorbent to obtain a plasticizer composition. The plasticizer composition was found to comprise 4-(2-ethyl-hexanoyloxymethyl)-cyclohexylmethyl ester conforming to Formula 1 (about 50% by weight) as a main component.

[0053] Preparation of polyvinyl chloride resin composition

[0054] Test specimens were prep...

Embodiment 2

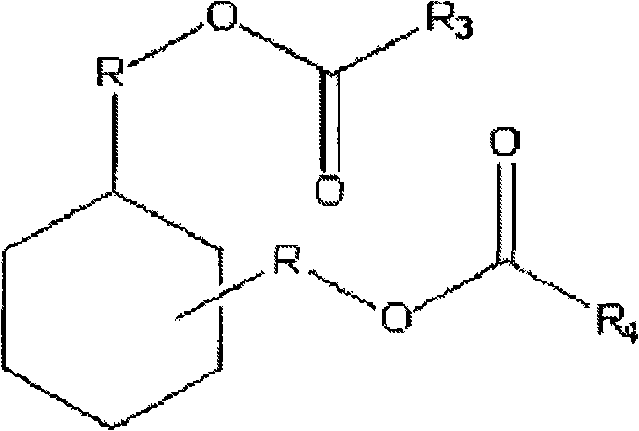

[0057] An ester plasticizer and a polyvinyl chloride resin composition were prepared in the same manner as in Example 1 except that capric acid was used instead of 2-ethylhexanoic acid. The test results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com