Novel low-density tobacco packet remoistening device

A loose moisture regain, low-strength technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of high energy consumption, high steam consumption, high construction cost, and achieve the goal of increasing installed power, reducing steam consumption, and improving utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

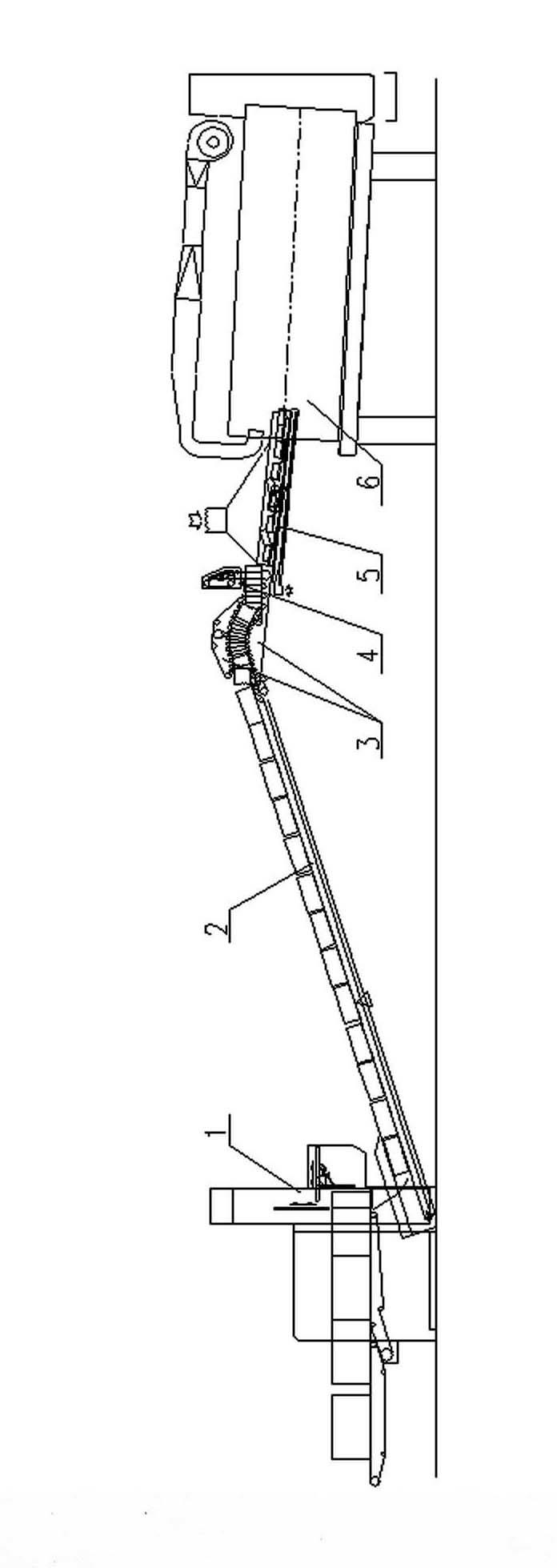

[0029] See figure 1 The system diagram of the low-strength loose moisture regainer shown. It includes a vertical slitting machine 1, and a belt conveyor 2 with a weighing function, an arc belt device 3, a fork knife mechanism 4, a vibrating tunnel 5 and a loosening dampening machine 6 are sequentially connected at the output end of the vertical slitting machine 1.

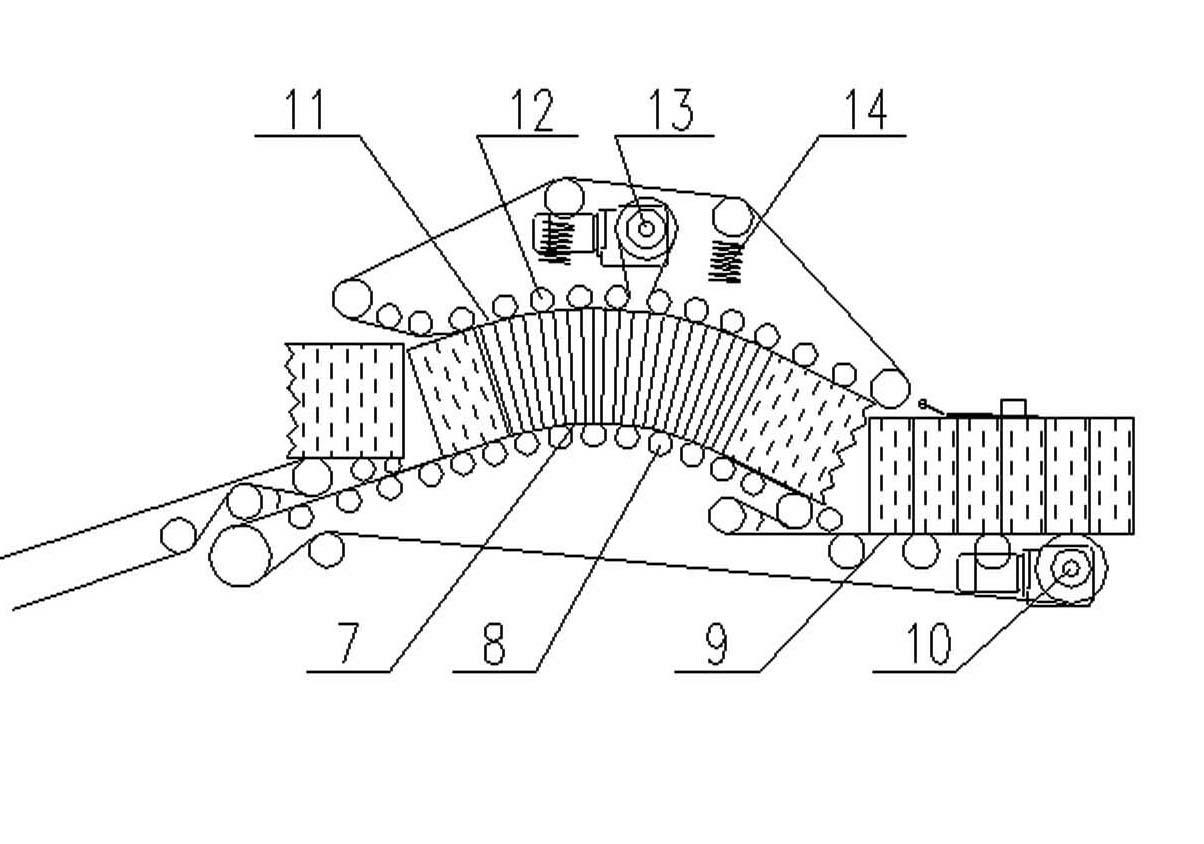

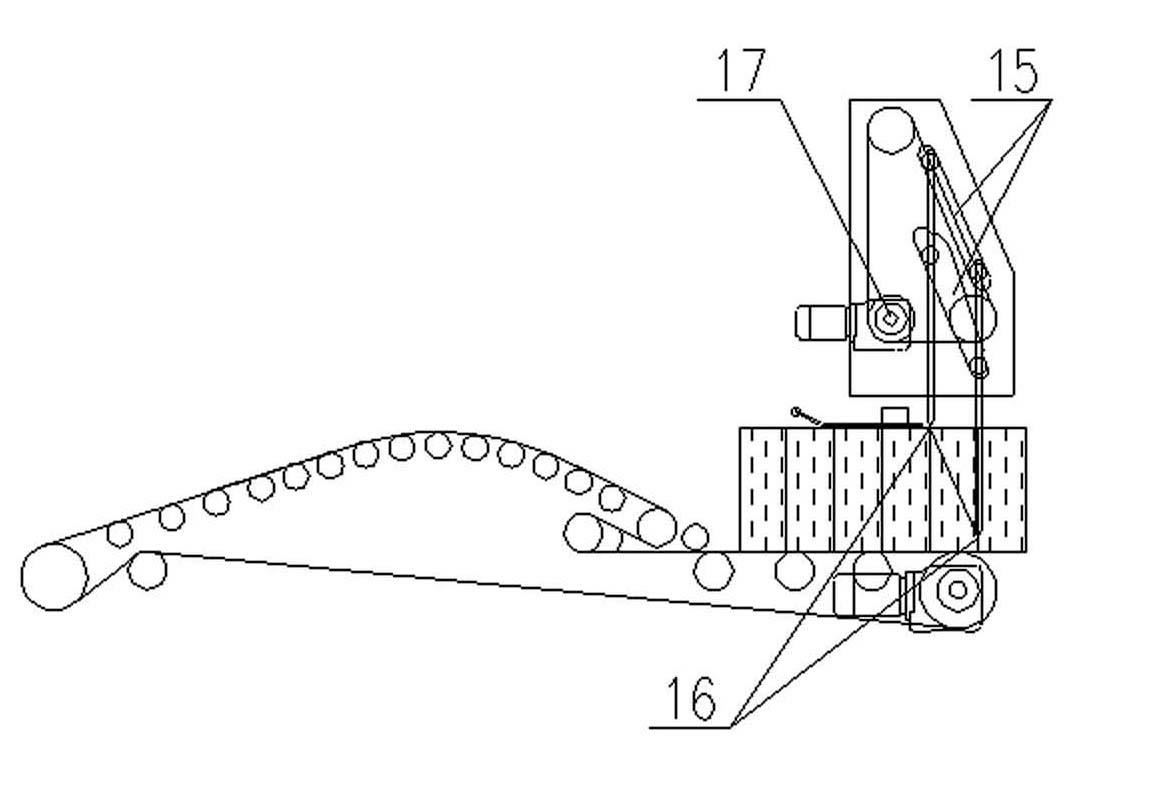

[0030] According to the application characteristics of the present invention, the pre-loosening device for multiple structures involved is an independent configuration of any structure, or a sequential combination of multiple structures.

[0031] figure 2The structure of the curved belt device is given. The arc belt device involved includes a group of roller tables 12 distributed in a concave arc shape, and an upper arc-shaped transmission belt formed by an endless belt 11 installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com