Step quenching heat treatment process for high-chromium grinding section

A technology of graded quenching and grinding, applied in the field of high-chromium cast iron, can solve the problems of easy loss of roundness and low hardness, and achieve the effects of reducing crushing, improving service life and improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

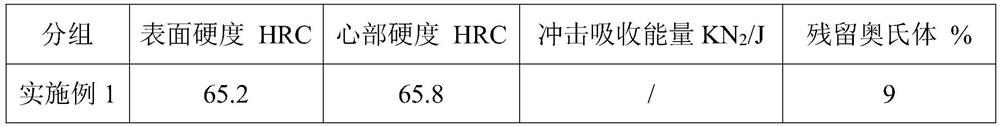

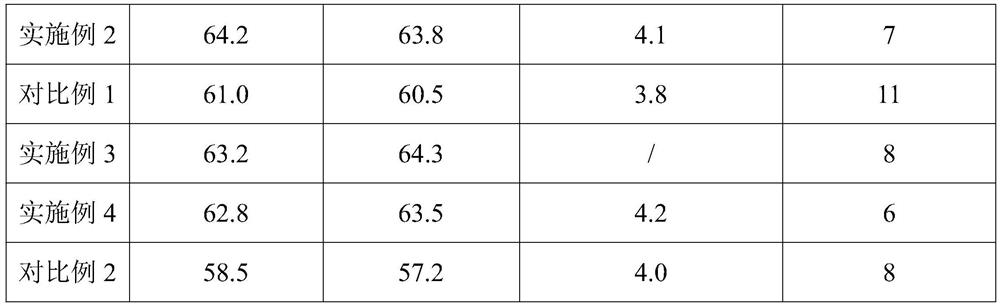

Examples

Embodiment 1

[0039] A heat treatment process for high chromium grinding segment graded quenching, comprising the following steps:

[0040] S1, the high chromium grinding section of Cr10-20mm * 25mm (its raw material comprises by weight percentage: C 2.9%, Cr10.3%, Si 0.75%, Mn 0.58%, S 0.027%, P 0.029%, the balance is Fe ) Austenitizing treatment is carried out in a continuous push rod heating furnace, the temperature in the holding zone of the heating furnace is 950°C, and the holding time in the holding zone is 220min;

[0041] S2. Take out the austenitized high-chromium grinding section from the continuous push rod heating furnace, put it into the quenching oil at 90°C, and keep it in the quenching oil for 4 minutes. At this time, the surface temperature of the high-chromium grinding section is 140 ℃, where the flash point of quenching oil is 230℃, the maximum cooling rate of quenching oil is 70℃ / s, and the kinematic viscosity of quenching oil at 100℃ is 70-80mm 2 / s;

[0042] S3. Tak...

Embodiment 2

[0045] A heat treatment process for high chromium grinding segment graded quenching, comprising the following steps:

[0046] S1, with the high chromium grinding section of Cr12-50mm * 70mm (its raw material comprises by weight percentage: C 2.75%, Cr12.32%, Si 0.78%, Mn 0.58%, S 0.028%, P 0.031%, surplus is Fe ) Austenitizing treatment is carried out in a continuous push rod heating furnace, the temperature in the holding zone of the heating furnace is 960°C, and the time in the holding zone is 200min;

[0047] S2. Take out the austenitized high chromium grinding section from the continuous push rod heating furnace, put it into the quenching oil at 100°C, and keep it in the quenching oil for 7 minutes. At this time, the surface temperature of the high chromium grinding section is 150 ℃, where the flash point of quenching oil is 230℃, the maximum cooling rate of quenching oil is 70℃ / s, and the kinematic viscosity of quenching oil at 100℃ is 70-80mm 2 / s;

[0048]S3. Take out...

Embodiment 3

[0051] A heat treatment process for high chromium grinding segment graded quenching, comprising the following steps:

[0052] S1, the high chromium grinding section of Cr18-40mm * 45mm (its raw material comprises by weight percentage: C 2.73%, Cr18.26%, Si 0.83%, Mn 0.62%, S 0.027%, P 0.025%, the balance is Fe ) Austenitizing treatment is carried out in a continuous push rod heating furnace, the temperature in the holding zone of the heating furnace is 1050°C, and the time in the holding zone is 200min;

[0053] S2. Take out the austenitized high chromium grinding section from the continuous push rod heating furnace, put it into the quenching oil at 90°C, and keep it in the quenching oil for 5 minutes. At this time, the surface temperature of the high chromium grinding section is 150 ℃, where the flash point of quenching oil is 230℃, the maximum cooling rate of quenching oil is 70℃ / s, and the kinematic viscosity of quenching oil at 100℃ is 70-80mm 2 / s;

[0054] S3. Take out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com