Novel large-cavity high-pressure device

A technology of high-pressure devices and large chambers, which is applied in the application of ultra-high pressure processes, pressure vessels used in chemical processes, etc., can solve the problem that secondary pressurized high-pressure devices are difficult to meet production requirements, high production costs, time-consuming and labor-intensive Problems such as pressurized block loss, etc., to achieve the effect of simple structure, convenient preparation and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

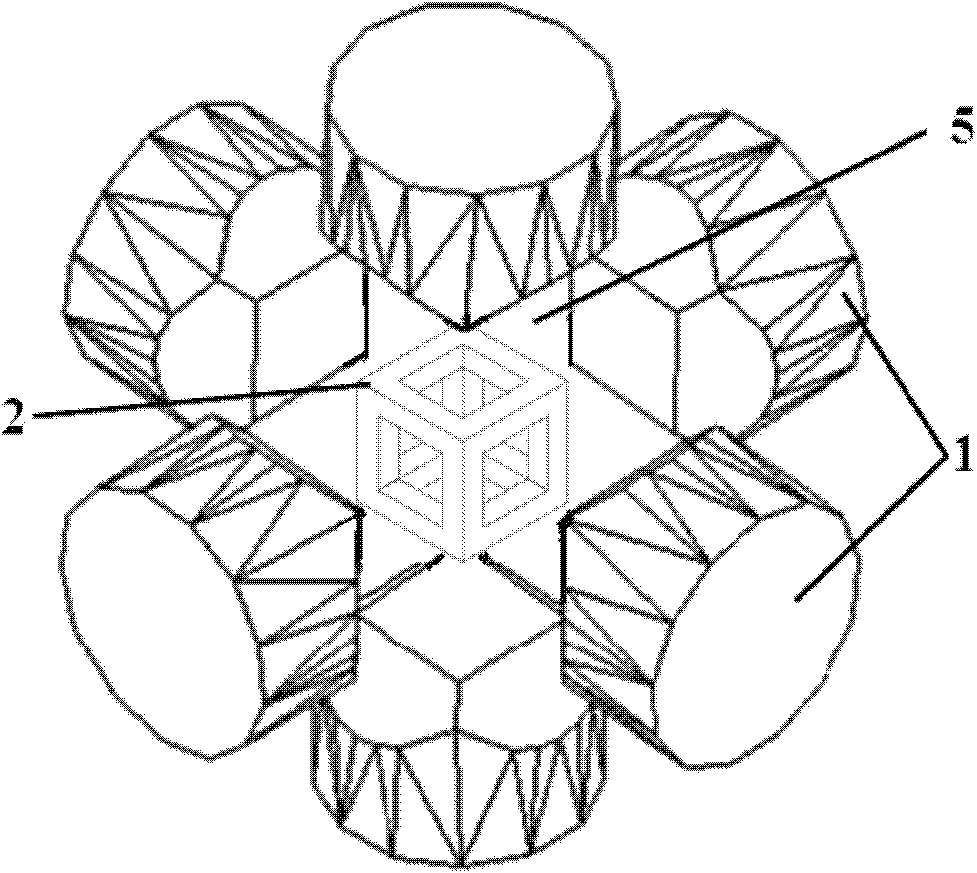

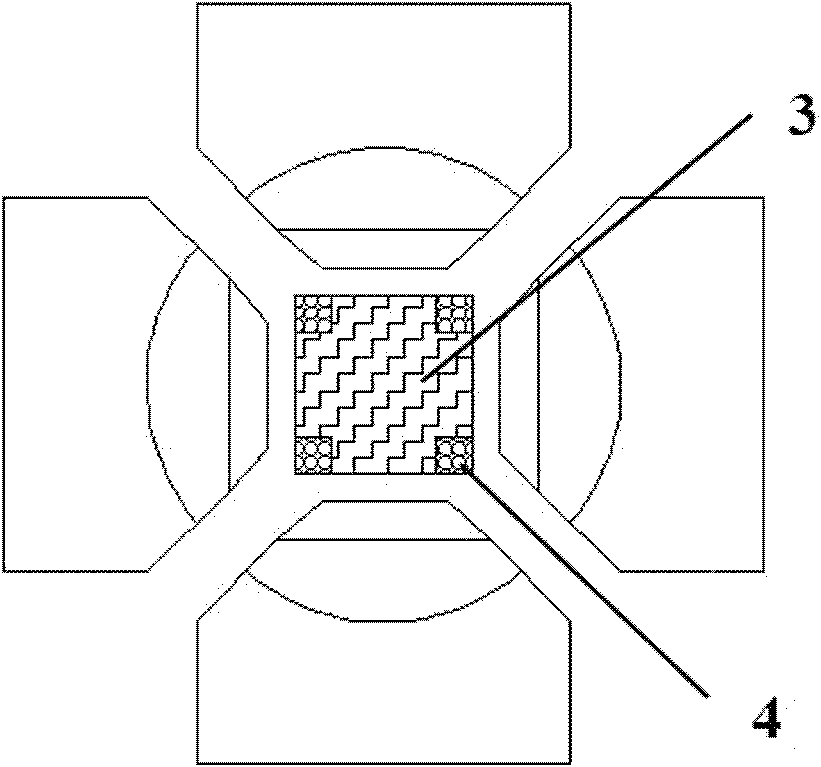

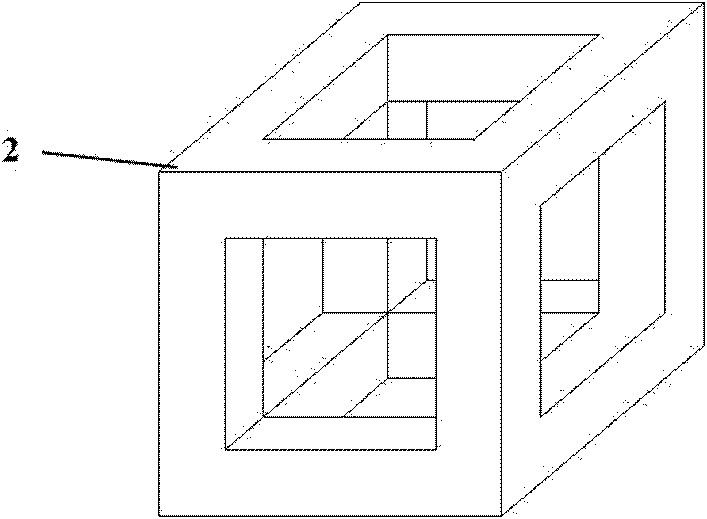

[0030] Such as Figure 1~6 As shown, the present invention has the characteristics of simple structure and low cost, and can flexibly choose the assembly method of pyrophyllite frame and pressure-transmitting medium composite block according to needs. The pyrophyllite frame and pressure-transmitting medium composite block can be selected as one-piece or modular Assembly. The device includes six top hammers 1 synchronously driven by a six-side top press, a pyrophyllite box 2 composed of twelve pyrophyllite strips 4, and a pressure-transmitting medium composite block 3 for containing synthetic raw materials. Among them, the pressure-transmitting medium composite block 3 is placed in the pyrophyllite box 2 to form a pressurizing unit. The pressurizing unit is placed in a high-pressure chamber 5 composed of six top hammers 1. The top hammer 1 is made of YG8 tungsten carbide cemented carbide. In order to make an appropriate amount of leaf wax serve as a sealing edge to protect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com