Impurity removal process for quartz sand

A technology of quartz sand and process, applied in the direction of magnetic separation, solid separation, wet separation, etc., can solve problems such as difficult removal, eutectic melting, and difficult production of high-purity quartz sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

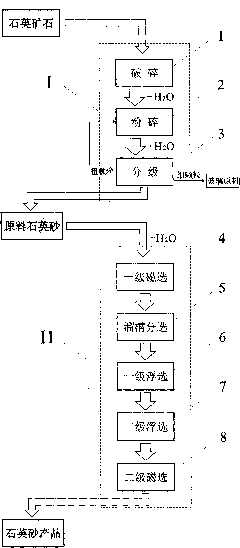

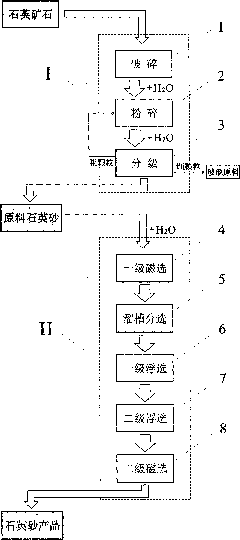

[0024] The invention includes two parts: an impurity analysis process and an ore dressing and impurity removal process.

[0025] The impurity analysis process is to directly crush the quartz ore through crushing, crushing and grading processes, so that the impurity minerals are separated from the quartz, and mainly appear as monomers in the quartz sand, so as to obtain the raw material quartz sand whose particle size meets the requirements. As a preferred solution, both the pulverization and classification processes adopt wet process.

[0026] The mineral processing and impurity removal process is to remove the mineral impurities in the quartz sand from the raw material quartz sand obtained through the impurity analysis process through magnetic separation, chute separation and flotation processes, and obtain quartz sand with particle size and impurity content that meet the requirements. Products, which provide raw materials for the follow-up process of high-purity quartz sand ...

Embodiment 2

[0040] Using the same raw material as in Example 1, except that the quartz mortar body is not subjected to chute sorting, the quartz sand product is obtained using the same process, method and equipment as in Example 1, and the quartz sand is sampled for impurity element analysis, the result See Table 1.

Embodiment 3

[0042] Using the same raw material as in Example 1, except that the quartz mortar body is not subjected to primary flotation 6, the same process, method and equipment as in Example 1 are used to obtain the quartz sand product, and the quartz sand is sampled for impurity element analysis. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com