T-shaped hydrostatic guide rail for precision finishing machine tool

A technology of hydrostatic guide rail and precision machining, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., and can solve the problems of poor rigidity and poor guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

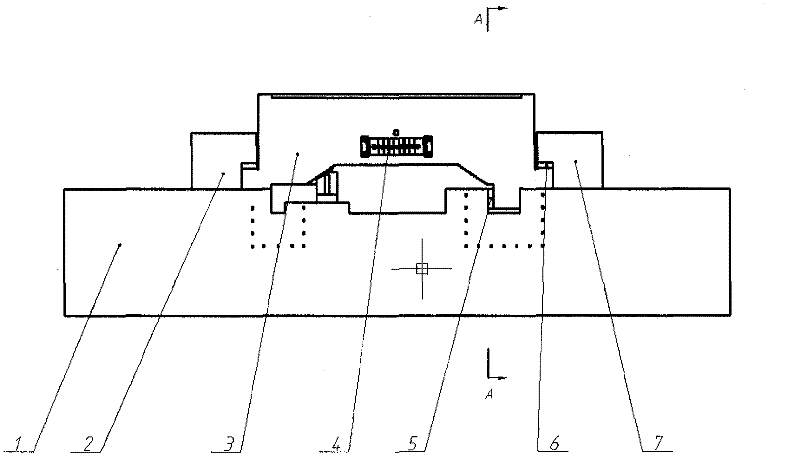

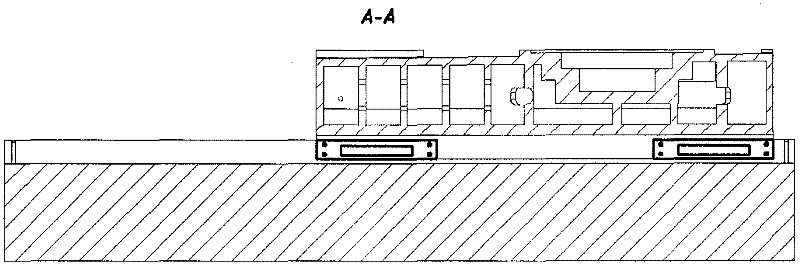

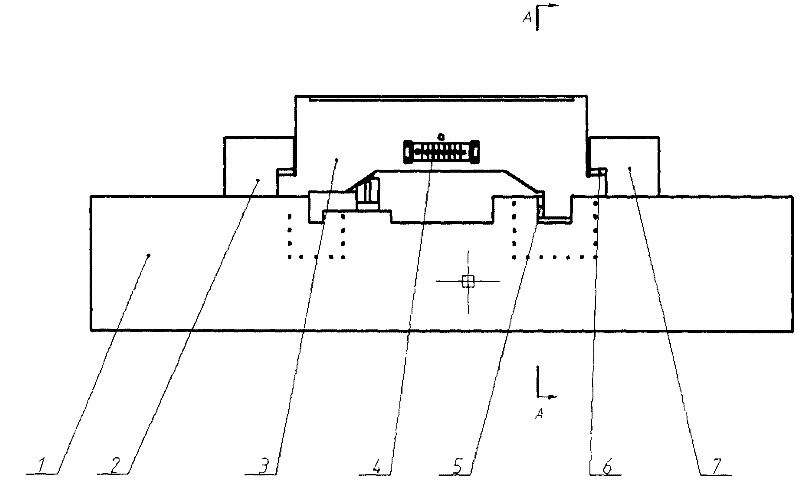

[0011] The structure and working principle of the T-shaped guide rail will be described below in conjunction with the accompanying drawings. Example 1, see figure 1 , where 1 is the granite bed, 2 is the left pressure plate, 3 is the cast iron sliding plate, 4 is the flow controller group, 5 is the horizontal static pressure block, 6 is the vertical static pressure block, and 7 is the right pressure plate. Among them, the horizontal static block see figure 2 As shown, the X axis is installed horizontally, and the quantity is 2 in total. Vertical static pressure block, installed vertically in X-axis, 3 pieces on one side, 6 pieces in total.

[0012] Working principle: Through the flow controller group 4, a certain pressure of lubricating oil is input into the static pressure chambers of the guide rails (the sliding plate 3 guide rail mating surface), forming a bearing oil film with a certain bearing capacity, floating the moving guide rails, and realizing guide rail pairing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com