Floating cover type dry fermentation biogas digester device

A dry fermentation and biogas tank technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc. Unsafe hidden dangers and other problems, to achieve the effect of convenient installation and adjustment, solving the problem of not being able to use in winter, and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described below in conjunction with the accompanying drawings.

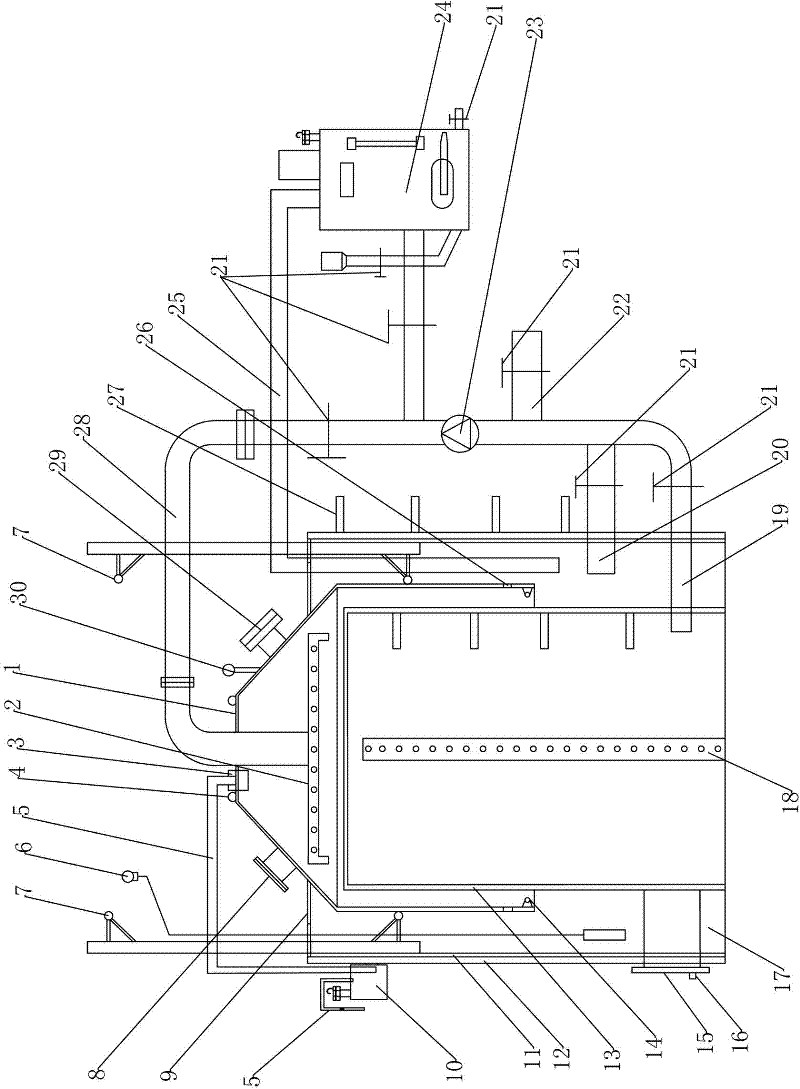

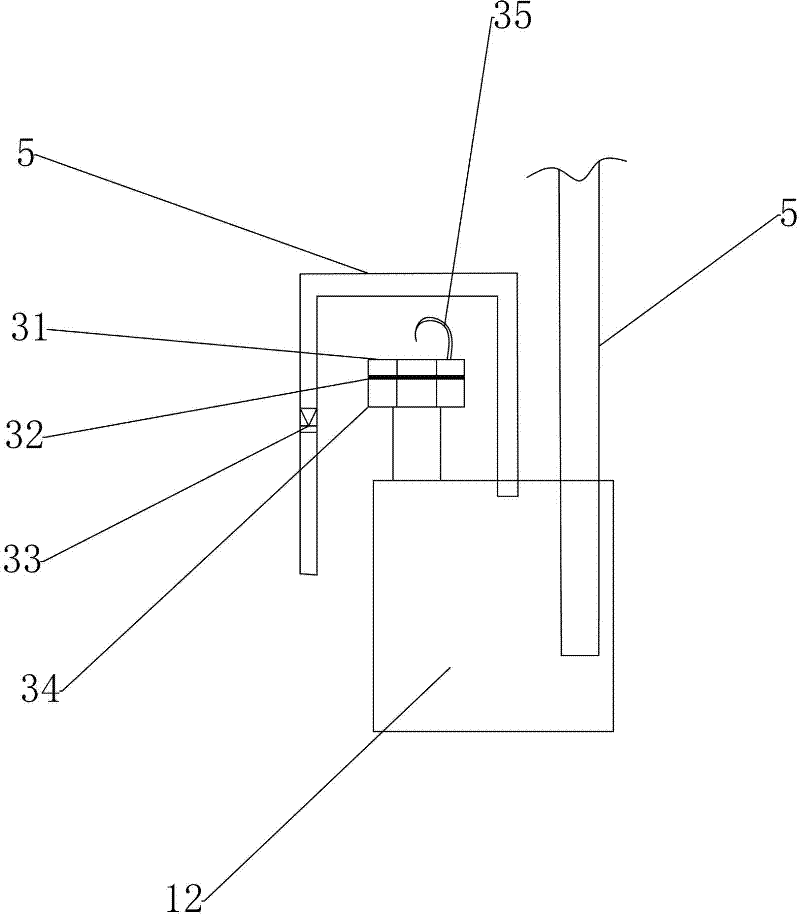

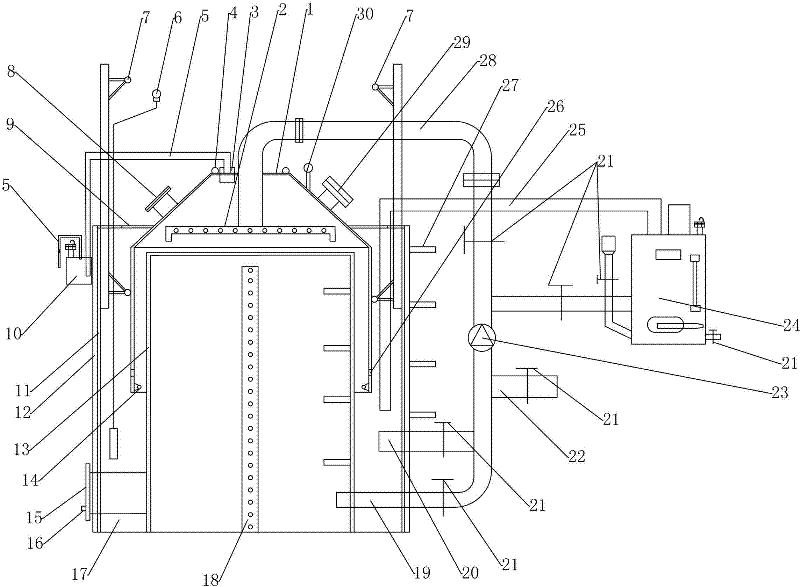

[0014] Depend on figure 1 It can be seen that the overall structure of the present invention, the floating cover type dry fermentation biogas tank device, is composed of an insulating layer 12, a sealed water tank 11, a dry fermentation tank 13, an air storage floating cover 1, a circulating mud pump 23, a steam boiler 24, etc. The outer side of the sealed water tank 11 is an insulating layer 12, and the sealed water tank 11 is located on the periphery of the dry fermentation tank 13, which plays the role of water storage and sealing. Located between the sealed water tank 11 and the dry fermentation tank 13, on the upper part of the dry fermentation tank 13, the gas transmission pressure is controlled by the weight of the air storage floating cover 1. There is an air guide pipe 18 in the dry fermentation tank 13, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com